| Pages:

1

..

14

15

16

17

18

..

27 |

Ral123

National Hazard

Posts: 735

Registered: 31-12-2011

Member Is Offline

Mood: No Mood

|

|

Why neutralize that much for 20% ammonium dynamite to be used the next day? I personaly (for egdn) place 20-30ml in a beaker with 100ml water. With

50cc syringe I suck water and blow it fast into the thing.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

It wasn't all used the next day, but yeah neutralization doesn't need to be very thorough at all if it is going to be used immediately. It maybe

didn't need to be so thoroughly neutralized but it was a safety precaution.

The rocks were blasted over a 1 to 2 week period, different rocks different locations. The person I was working with was using the rocks for shoreline

preservation, or rip rap I think they call it. Any rocks over 12-15 tonnes and dependant on location were just too big for the loader.

In the end a couple more charges were needed so a little more was made and a very quick and dirty neutralization was done and the NG used on the same

day.

For me the most annoying but necessary part of a NG synthesis, if it is to be stored for any length of time, is the neutralization. A circulating

bicarb solution wash & agitation has potential I think.

I am looking into the bubble pump thing right now because it has no moving parts that could potentially set of the NG. The results of using the

centrifugal pump were very positive. When using the centrifugal pump from the table-top fountain a very thorough acid neutralization, of ~15g of NG,

was done in 20 minutes or so. I would normally be messing around for a day or more, with occasional swirling, trying to get it neutral with even 15

grams.

The very first time I made NG I had no clue what I was doing (very bad move!). I made it no problem but I hadn't learned yet that the residual acidity

had to be neutralized. I think I washed it once with water or something. When I went out the next morning to check on the 10g or so, it was boiling

and spewing red fumes. I immediately disposed of it, and the experience left an impression. If that had been a large amount, it would have been a bad

situation.

[Edited on 17-4-2012 by Hennig Brand]

|

|

|

Ral123

National Hazard

Posts: 735

Registered: 31-12-2011

Member Is Offline

Mood: No Mood

|

|

Why more west type guys love NG so much and the guys from the east (russian pyros) like egdn much more?  May be no NG with 60% nitric May be no NG with 60% nitric

|

|

|

caterpillar

Hazard to Others

Posts: 472

Registered: 8-1-2012

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Ral123  | Why more west type guys love NG so much and the guys from the east (russian pyros) like egdn much more?  May be no NG with 60% nitric May be no NG with 60% nitric

|

My proposition: russian boys live in the cold country, therefore they want to use something with lower melting point, than NG. It may be joke, but my

friend (same person, who made 1.5 l of NG at once), used in fact mixture of glycerol and EG to lower melting point of resulting product. It was in a

forest in a spring and he used snow to cool basin with mixed acid.

Women are more perilous sometimes, than any hi explosive.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I live in Canada and it gets pretty cold a lot of the time. I have made EGDN a few times, mostly just to mix with NG on those cold days. I like NG,

which may be just because I am more used to it. A few positive attributes of NG as I see it are its higher density, higher viscosity, lower solubility

and lower vapor pressure. All that being said EGDN is great stuff in colder climates, where pure NG often can't function at all. Apparently EGDN

doesn't suffer from low order detonation, which can be a real problem with NG if not initiated properly. They are both good, just different.

I have seen people write than EGDN is more storage stable than NG. I wonder how much more?

[Edited on 18-4-2012 by Hennig Brand]

|

|

|

Ral123

National Hazard

Posts: 735

Registered: 31-12-2011

Member Is Offline

Mood: No Mood

|

|

6 months old sample looked good, till I got rid of it  NG would be perfect

dream if it was stable... NG would be perfect

dream if it was stable...

|

|

|

Bot0nist

International Hazard

Posts: 1559

Registered: 15-2-2011

Location: Right behind you.

Member Is Offline

Mood: Streching my cotyledons.

|

|

Six months with no deterioration sounds stable to me. I think your confusing stable with sensitive to stimuli. Stable implies chemical stability, not

susceptibility to explosive decomposition from various stimuli.

U.T.F.S.E. and learn the joys of autodidacticism!

Don't judge each day only by the harvest you reap, but also by the seeds you sow.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

So EGDN is known for being less sensitive in terms of explosive initiation, not storage stability? I think I have heard both, but I could be wrong.

The longest I have ever stored a sample of NG was about 3 years. It was very well washed and ~all acidity well neutralized. When it was made it was

nice and clear because I used boiled down electrolyte for H2SO4, HNO3 and nice clear glycerin. It was kept in a fairly dark location with no direct

sunlight and kept fairly cool (below 22C at all times). After 3 years it was still perfectly clear and had excellent performance when I did eventually

use it. If NG is well neutralized and stored with a bit of care it seems quite storage stable.

I am in too much of a rush right now to find a reference but isn't there a sample of nitroglycerin that is really old (like 100 years or something)

stored by the Nobel scientists at a museum or something. I think it is taken out and checked periodically and any formed acidity neutralized, but it

is still really old.

[Edited on 18-4-2012 by Hennig Brand]

|

|

|

Bot0nist

International Hazard

Posts: 1559

Registered: 15-2-2011

Location: Right behind you.

Member Is Offline

Mood: Streching my cotyledons.

|

|

Yes, that is correct about the old sample. When properly stabilized and neutral it would seem it could be stored indefinitely.

U.T.F.S.E. and learn the joys of autodidacticism!

Don't judge each day only by the harvest you reap, but also by the seeds you sow.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Yeah, NG is quite stable when treated properly however,

Regarding EGDN stability vs. NG stability

This is from Wikipedia, not the best reference but they are usually right, and it makes sense.

"It (EGDN) is considerably more stable than glycerol trinitrate owing to the lack of secondary hydroxyl groups in the precursor polyol."

I still like NG though, mostly because of the handling properties.

[Edited on 18-4-2012 by Hennig Brand]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Here is a snip-it from the section on laboratory synthesis of NG in Nitroglycerin & Nitroglycerin Explosives by Naoum.

It sounds like at higher temperatures (40-50C) and manually "shaking" the NG in bicarb solution the acid neutralization is trivial (few minute

process).

Sounds too easy but maybe it is. I think I still like the idea of having an automated acid neutralization process and being well away from it during

the agitation.

[Edited on 19-4-2012 by Hennig Brand]

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

In his book ("Nitroglycerin & Nitroglycerin Explosives by Naoum"), I believe in chapter 7 he has some "Plant Lay-Outs" & brings up some

concepts that have been used successfully for many decades. The use of compressed air for mixing had apparently been common (& safe) in Europe as

well as a contact wash with a carbonate and saline water. There is a sharp separation of the nitrated glycerin and acids even down to 10% (according

to Naoum) & apparently this presented a problem during that time as serration funnels had no Teflon for the development of the petcock. However

even with such a mechanism I had thought it wise to rotate the valve several times prior to active separation. He quotes 1.6 for NG (at that time) due

to fatty acids yet today's glycerin sources may be so pure as to reduce that figure.

One challenge with EDGN is that it's substantially more viscous (than NG) & separation is somewhat more troublesome without a very bright

background light.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Sounds good, I will read those parts right away. I haven't yet sat down and read the whole book, just skimmed it. Reading it all the way through is on

my to do list, it is a very interesting book.

I think NG is more viscous than EGDN though. The more viscosity, or the more resistance between layers if you will, the harder it is to pour etc.

Edit:

I see what you mean (I think), the EGDN would be much harder to separate from water because its viscosity is so much closer to that of water.

I found another NG data page from a company that makes NG amoung other nitric esters.

Attachment: NG Data Page 2.pdf (17kB)

This file has been downloaded 776 times

Notice the viscosity of NG is stated as 36 cP at 20 C, and water is close to 1 cP at 20 C I think. Quite a difference.

Here is a reference for the viscosity of EGDN.

EGDN Viscosity:

4.2 mPa.s at 20 deg C --->(1 mPa.s = 1 cP)

[Kirk-Othmer Encyclopedia of Chemical Technology. 3rd ed., Volumes 1-26. New York, NY: John Wiley and Sons, 1978-1984., p. V9: 573 (1980)] **PEER

REVIEWED**

And also for NG from the same source.

NG Viscosity:

36.0 centipoise @ 20 deg C

[Kirk-Othmer Encyclopedia of Chemical Technology. 4th ed. Volumes 1: New York, NY. John Wiley and Sons, 1991-Present., p. V10 (1993) 22] **PEER

REVIEWED**

[Edited on 20-4-2012 by Hennig Brand]

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

Remember however that's a really old text. (I think) the glycerin was from the soap industry and somewhat impure. It may be that was one reason why we

can achieve such a clean final product; in that the starting material has few impurities.

The toughest separation (visually) I had seen was propylene glycol - unless you have the brightest of lighting it really tough to see the layer. Amyl

Acetate and ethanol appear to layer separate double-base smokeless powder However the graphite in some samples make virtually any movement "muddy-up"

the division.

I am guessing at this but I think that the only NG manufacturing done in the USA may be for DBSP. I had a very fine pipette unit that could draw off

the layer without disturbing the other materials and the NG blotted in paper as fast as EDGN.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Feel free to point out any mistakes in my theory, there probably are at least a few.

This is what I remember from a class last year and a little googling right now.

I don't know that much about it but I think when a liquid blots or soaks up in cellulose material it has a lot to do with the bonding between the

liquid and the cellulose.

As an example, since cellulose is unsaturated and has the hydroxyl groups it bonds well with water. This is primarily because of Hydrogen Bonding

between the water and the cellulose. Put a little water at one end of a dry cotton cloth and it will soak or spread along the cloth because of the

weak bonds between the water and the cellulose/cotton. On the other hand if you put a little gasoline, which is a saturated hydrocarbon (no hydroxyl

groups), at one end of the same dry cloth it will not spread very well because the bonding forces aren't there.

NG and EGDN both have hydrogen together with nitrogen and oxygen which means they are polar and there is hydrogen bonding between molecules for both

esters. There is also hydrogen bonding between them and other polar molecules.

Maybe what you are seeing has something to do with different bond strengths between the cellulose/paper and the NG and EGDN. I am assuming it would be

a little different for NG and EGDN.

The Viscosity of the nitric ester would also affect the flow rate into the cloth or paper as well I think. Higher viscosity, higher resistance to

flow.

Edit:

I wasn't thinking. NG has very low water solubility, so I guess that makes it only very slightly polar. EGDN is much more water soluble than NG,

making it more polar. It would make sense that EGDN would blot into paper/cotton faster for this reason.

I suppose the electronegative N's and O's are not bonded directly to the H's in either NG or EGDN.

The impurities in the old fashioned glycerin would be saturated, very nonpolar, fatty molecules which if present in the NG made from it would cause

the NG to not blot into cellulose/paper as quickly or as thoroughly. I see what you are getting at, but it took a while.

[Edited on 21-4-2012 by Hennig Brand]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

You know the more mono & di-nitroglycerine that is present in a sample of NG would also case the sample to blot more quickly into paper. This is

basically the same reason the lower nitrates of NG are more soluble in water as well, the hydroxyl groups.

I guess most of the lower nitrates would be dissolved/ washed away during the washing, but the saturated impurities wouldn't be.

MNT from NG Synthesis Spent Acid

BTW, has anyone used the spent acid from NG manufacture to produce Mono-Nitrotoluene. I was reading about it in Naoum, so decided to give it a try. It

works beautifully! The nitration of Toluene is not an equilibrium reaction like an esterification reaction is (NG), so the water in the waste acid

isn't much of a problem. More than 95% of the remaining nitric acid in the waste acid can be utilized when used to nitrate toluene to MNT.

I suppose the waste acid from NG manufacture could be used to nitrate other aromatics as well.

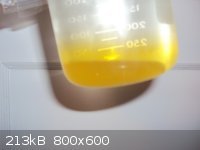

Here is a picture of the MNT made from 75 mL or so of spent acid from a NG synthesis. It is being washed in water. I will probably nitrate it to at

least DNT, so the intermediate washing probably wasn't needed. The MNT could be used as is to make a Cheddite or Sprengel explosive (?) with potassium

chlorate. The DNT/chlorate explosives are more powerful and make better use of materials than the MNT/chlorate types I think. It is also very easy to

get high yields of DNT without the strongest of acids. With TNT it is a little more difficult to get good yields (I think).

[Edited on 22-4-2012 by Hennig Brand]

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

I've tried a 2-pot synthesis that worked out fairly well (it's posted back a few years ago). Because it's mp was 80C and it had cleaned up a

tan-beige, I was surprised. I started out with bright yellow long (2cm) needles that were vivid yellow before a H2SO4 wash. I've tried many one pot

labs and never got tri-nitrated material.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Thats interesting. I attempted TNT before using AN and H2SO4, but the product I ended up with had a melting point below 70C. I later read that even

very small amounts of DNT lower the melting point of TNT a lot.

The main focus of my last post was on using the left over acid from a NG synthesis to nitrate toluene to MNT. That is how the MNT in the above picture

was made, from spent mixed acids from a NG synthesis.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

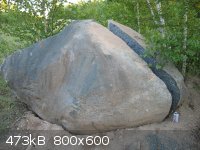

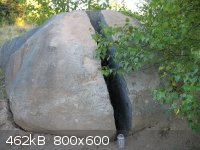

I mentioned doing some rock blasting on the last page of this thread. I found some of my old pictures. Here are 3 views of one of the more successful

blasts. It was a successful blast because the rock was broken into three large pieces and not a bunch of smaller ones. Large pieces were desirable

because of what the rock was to be used for. The whole rock was just too big to move in one piece with the available equipment.

BTW, IIRC the granite rock was about 15 tonnes and the charge used was 100g of 20% ammonia dynamite. If I was to do it all over again I would try only

10% ammonia dynamite, which I think might cut down on the amount of smaller pieces produced. This particular blast was successful however, with no

excessive shattering of the rock.

[Edited on 23-5-2012 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Vikascoder

Hazard to Others

Posts: 309

Registered: 28-1-2012

Member Is Offline

Mood: No Mood

|

|

is it possible to make dynamite with fullers earth by absorbing bitroglycerine in it or by absorbing nitroglycerine in sand which is used for

construction purposes

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

From the little bit I have read about it, fullers earth sounds promising. It is apparently a very good absorber of many things. The COPAE (p 332)

implies that diatomaceous earth and fullers earth are the same thing. Reading modern descriptions of both clearly shows that they are similar but not

the same. Apparently fullers earth varies in its composition from source to source as well. It does sound like it is used for many of the some

purposes as diatomaceous earth though, which is promising.

Mixing sand with NG sounds like a good way to reduce your life expectancy. Sand has low porosity and absorptive qualities and is also hard and gritty.

Mixing liquid NG with hard gritty things is a bad idea!

There are many materials in modern times that can be used to absorb NG. The first really successful absorbent, which is also naturally occurring, was

diatomaceous earth. Alfred Nobel discovered that is could absorb several times its weight in NG.

The follow is a copy/paste from the Wikipedia page on diatomaceous earth.

"Diatomaceous earth also known as D.E., diatomite, or kieselgur/kieselguhr, is a naturally occurring, soft, siliceous sedimentary rock that is easily

crumbled into a fine white to off-white powder. It has a particle size ranging from less than 1 micrometre to more than 1 millimeter, but typically 10

to 200 micrometres. This powder has an abrasive feel, similar to pumice powder, and is very light as a result of its high porosity. The typical

chemical composition of oven-dried diatomaceous earth is 80 to 90% silica, with 2 to 4% alumina (attributed mostly to clay minerals) and 0.5 to 2%

iron oxide."

[Edited on 3-6-2012 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Vikascoder

Hazard to Others

Posts: 309

Registered: 28-1-2012

Member Is Offline

Mood: No Mood

|

|

Friends i started with 8 ml of normally glycerin to make nitroglycerin . I completly neutralized and washed it with water . But my finally product is

15 ml which also contains water . How could i dry my nitroglycerin completely.

|

|

|

Fossil

Hazard to Others

Posts: 131

Registered: 4-4-2012

Location: Canada

Member Is Offline

Mood: No Mood

|

|

Put it in a saturated salt (NaCl) solution.

|

|

|

Vikascoder

Hazard to Others

Posts: 309

Registered: 28-1-2012

Member Is Offline

Mood: No Mood

|

|

I have already put it in NaCl solution . After that i got 15 ml of nitro glycerine . Now without further drying or desicating i just tried to detonate

it by dipping a piece of 1 cm square of paper . It detonated with a very nice bang when hit with hammer. I think there is no further need to dry it .

It is ready to be used as explosive.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I used to use a saturated NaCl solution to dry NG, but I find now that it is usually just extra bother to do so. If one is not too impatient, simply

exposing an open container of the wet NG to the open air for a while will dry it fairly quickly. NG is very non-polar, and bonds only very weakly with

water. I usually just leave some NG out over night in a beaker and by morning it is nice and clear and dry. Don't worry about losing NG, as it has

very low vapor pressure at room temperature.

[Edited on 9-6-2012 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

| Pages:

1

..

14

15

16

17

18

..

27 |