| Pages:

1

..

29

30

31

32

33

..

68 |

grndpndr

National Hazard

Posts: 508

Registered: 9-7-2006

Member Is Offline

Mood: No Mood

|

|

Youtube Explosively formed penetrators hes under the name incognito oo1 look in the post above yours for specifics.

I got nothin against the guy Hissingnoise except BS pees me off

PS look at the video carefully once he gets to the device atop the target 'cylinder'(the target dwarfs the device?wieght guestimates) its light tan

looks very much like debarked sec tion of a log and a final shot of the top of the target reveals growth rings lighter outer wood and inner dark

sapwood!Not a characteristic of metal fellas

[Edited on 11-12-2010 by grndpndr]

|

|

|

NUKE

Harmless

Posts: 17

Registered: 21-2-2006

Location: Slovenia

Member Is Offline

Mood: Detonating with the highest order

|

|

I think he might have been referring to one those two videos (both are practically identical at least as far as "shaped charge material" is

considered)

http://www.youtube.com/watch?v=Ua0F68etB0M

http://www.youtube.com/watch?v=w0Xk-TgGcDE

http://www.2shared.com/file/J-4Fsmxe/compilation_material.ht...

There you go, higher resolution of pictures I presume you were referring to. Cannot give you any more than that

My explaination: inequal distribution of water on dirty rusty target

[Edited on 14-12-2010 by NUKE]

|

|

|

Microtek

National Hazard

Posts: 869

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

If that's a "debarked log", it's the most perfectly straight one I've ever seen. And those "growth rings" look quite a lot like machining marks to me.

grndpndr, I think you should stop pursuing this and just acknowledge that you were wrong (in fact I thought you did). You'll end up making a fool of

yourself by persisting.

|

|

|

grndpndr

National Hazard

Posts: 508

Registered: 9-7-2006

Member Is Offline

Mood: No Mood

|

|

Then with all due respect you havent seen many trees Microteck ,and my world doesnt revolve around my reputation here,I been round the block more

than a few times.FWIW I think nukes work is outstanding . A founding member judging by his join date/post count I communicate with has/had a high

opinion of Nukes/ incognitus001 work as well but he has indicated to me the photos bother him as well so Im not as alone as you would think.His CSC

appears to have one of the finest cones ive seen from a garage.The tubing appears to be seamless quality well casing from what little I can see of the

booster that may be a machining of his as well.Though effective using hose clamps instead of welding is about the only change I could think of .OT

improving the photography of the suspect target

I think the listv of photos starts on page .These 3 are by far the most troublesome.Thers No photoghraphic faux paux that causes whats happened in

those 3 photos perioud.No lighting ,dirty rain,overexposed film cause a solid steel cylinder to split like a logWith a CSC of that quality.Ive had

several people look at the offending photos and w/o exception fraud was the conclusion.I dont really care if your trying to pound smoke up somewhere

but if theres smoke thers fire.If thers a reason i dont care either but I know what Im seeing.

[Edited on 16-12-2010 by grndpndr]

|

|

|

magneet

Harmless

Posts: 19

Registered: 30-12-2007

Location: on a forum somewhere

Member Is Offline

Mood: lurking mostly

|

|

| Quote: |

Thers No photoghraphic faux paux that causes whats happened in those 3 photos perioud.No lighting ,dirty rain,overexposed film cause a solid steel

cylinder to split like a logWith a CSC of that quality

|

Maybey not the jet, but the shockwave arriving later causing brittle meltcasted iron to fall apart.

Hi,

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

lack of experience, my guess would be he was either a radio officer or the camp-cook during service, lol...

|

|

|

Microtek

National Hazard

Posts: 869

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

Have you looked at the higher resolution pictures that NUKE provided? I suppose you could possibly make a piece of wood or plastic look like that with

massive amounts of work and a flair for movie effects - but it would be much easier to make a quality shaped charge and penetrate it as NUKE has

described.

I may not have extensive experience with all of the species of log on the planet, but I have fired my fair share of shaped charges into both steel and

wood. I can tell you that wood doesn't behave like what we see in the pictures when hit by a SC, at least when the jet hits perpendicular to the

fibres.

The pictures show what you would expect to see when an SC jet penetrates a relatively brittle target such as some types of cast iron. As I have

explained to you previously, much of the material that used to be where the hole is after the penetration is not expelled out the back of the target,

but instead pushed radially away from the channel. This produces tremendous stress in the target and would very probably fracture the target as shown.

|

|

|

franklyn

International Hazard

Posts: 3026

Registered: 30-5-2006

Location: Da Big Apple

Member Is Offline

Mood: No Mood

|

|

Computer Simulation of Explosively Formed Projectiles

http://www.mater.upm.es/isb2007/Proceedings/PDF/Volume_1/Vol.I(20)WM14.pdf

Manual for Shaped-Charge Design

Cited by octogen - www.sciencemadness.org/talk/viewthread.php?tid=10575&pag...

http://handle.dtic.mil/100.2/ADB954297

Redirects to :

http://www.dtic.mil/cgi-bin/GetTRDoc?AD=ADB954297&Locati...

.

|

|

|

grndpndr

National Hazard

Posts: 508

Registered: 9-7-2006

Member Is Offline

Mood: No Mood

|

|

Well, where to start.My apologys first and foremost to NUKE. Ive reviewed the new Pics and they certainly seem genuine to me.If these same pics of

the pieces of the target had been posted with the same clarity to begin with this misunderstanding would have been avoided altogether. I

I would never have questioned their authenticity and saved myself the embarressment(Pg. 27,9 photos- retrieved pieces).

Still. the tgt metal had to be quite brittle judging by the entrance/exit and general shattering of the target..Even before I had seen the enhanced

pictures I did give credit where I thought it was due.The cone in particular seemed well made(obviously the entire device well designed/made) and Im

still curious as to its origin, but brittle cast iron/ or not 5x CD penetration from an imp device is impressive.In fact the Carl Gustav 84mm RR HEAT

RD is reputed to be capable of penetrating in excess of 400 mm

RHA!

Whatever metal( iron/mild steel) the target was thats good company and excellent work Nuke. Again ,My apologys.

[Edited on 26-12-2010 by grndpndr]

|

|

|

The WiZard is In

International Hazard

Posts: 1617

Registered: 3-4-2010

Member Is Offline

Mood: No Mood

|

|

Assorted refs

I am not about to peruse 31 pages of posts so forgive me if

these are not new upon the collective.

As previously suggested dtic.mil is treasure trove of information.

A quick look turned up these.

William P Walters

Explosive Loading of Metals and Related Topics

ADB102693

The Shape Charge Concept

Part 1, Introduction ADA226401

Part 2, The History of Shaped Charges ADA226772

Part 3, Applications of Shaped Charges ADA228492

Introduction to Shaped Charges

And a SL more than I have time time on earth too read!

|

|

|

The WiZard is In

International Hazard

Posts: 1617

Registered: 3-4-2010

Member Is Offline

Mood: No Mood

|

|

Uses for shaped charges your mother never told you about

Just finished reading Willaim F. Walters three-part The Shaped

Charge Concept. 1990.

Part III.

A shaped charge meteor simulator was developed for NASA (Need

Another Seven Astronauts) A rocket was used to carry the charge

above the atmosphere , “turn and allow the detonation of the

shaped charge to accelerate at hypervelocity through the earths

atmosphere. The intent was to simulate a body (meteor)

re-entering the earth’s atmosphere.” A nickel – iron liner was used.

Using a Aerobee rocket launched from Alamogordo, NM October

16, 1957 “the first particles from a shaped charge jet were

successfully launched into orbit about the sun.”

A really stupid-stupid-stupid experiment “was contemplated that

would allow the jet to impact a heavenly body, such as the moon.

A spectroscopic analysis of the impact; flashes would reveal the

elementary chemical composition of the moon’s surface. The later

experiment although feasible, was never carried out.”

“… two unlined cavity conical shaped charges improvised from

coffee cans (used as the casing) and 10 pounds of C4 explosive

felled trees of up to 34 inches in diameter when detonated in

diametric opposition to each other. Larger diameter trees were

felled by multiples of 3- 5 charges detonated symmetrically at

points one-third to one-fifth of the circumference of the trees.”

I am of the drill a hole in the tree and insert dynamite school of

though. Or if there is no rush … drill two holes and pour in white

arsenic dissolved in sodium hydroxide.

Takes several months – a dead tree is guaranteed.

Bet you didn’t know there was a US patent on dissolving (white)

arsenic oxide in sodium hydroxide!

djh

----

Today's chemical trivia question —

At room temp after mercury this

is the second heaviest liquid ?

|

|

|

The WiZard is In

International Hazard

Posts: 1617

Registered: 3-4-2010

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by The WiZard is In  | Just finished reading Willaim F. Walters three-part The Shaped

Charge Concept. 1990.

Part III.

A shaped charge meteor simulator was developed for NASA (Need

Another Seven Astronauts) A rocket was used to carry the charge

above the atmosphere , “turn and allow the detonation of the

shaped charge to accelerate at hypervelocity through the earths

atmosphere. The intent was to simulate a body (meteor)

re-entering the earth’s atmosphere.” A nickel – iron liner was used. |

From NASA — more than most really want to be knowing

me thinks.

http://tinyurl.com/29myhvt

|

|

|

franklyn

International Hazard

Posts: 3026

Registered: 30-5-2006

Location: Da Big Apple

Member Is Offline

Mood: No Mood

|

|

Good Find Wiz,

direct links for cited NASA papers

Development and testing of advanced shaped charge meteoritic simulators.

Part I - Shaped charge design and development

http://hdl.handle.net/2060/19670008288

Redirects to:

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/1967000...

Development and testing of advanced shaped charge meteoritic simulators.

Part II - Calibration of flight guns

http://hdl.handle.net/2060/19670008289

Redirects to:

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/1967000...

Design, development and testing of bi-explosive shaped charge meteoritic simulators

http://hdl.handle.net/2060/19680021751

Redirects to:

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/1968002...

Explosive oxidations initiated by simulated meteoroid penetration into spacecraft atmospheres

http://hdl.handle.net/2060/19710010761

Redirects to:

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/1971001...

- cited in the bibliography of the paper above -

Oxidative Detonations Initiated by High Velocity Impacts , AFFDL-TR-65-41

http://handle.dtic.mil/100.2/AD466558

Redirects to:

http://www.dtic.mil/cgi-bin/GetTRDoc?AD=AD466558&Locatio...

The last two above treat the incendiary effects of liner material. Imagine for example

Cesium explosively driven into an oxidizer tank, or even just water. Metal hydrides

explosively decompose on their own when liquified, something I had mentioned in passing

at the end of the following post.

http://www.sciencemadness.org/talk/viewthread.php?tid=10575&...

.

|

|

|

grndpndr

National Hazard

Posts: 508

Registered: 9-7-2006

Member Is Offline

Mood: No Mood

|

|

On the topic of unconventional shaped charges. A couple of shaped charges Ive mentioned before here are the Saddle charge and Diamond charge.

From an old FM,5-25 Explosives and Demolitions circa '67' are illustrated and formulas

given for explosive wieghts/shapes for cutting billets of various steel alloys.

The first is called a saddle charge for use in cutting solid steel billet material up to 6-8 in in diameter.

Above 6-8in diameter/high carbon alloy steels a Diamond charge is reccomended .

Appearing to be a elongated triangle the SADDLE charge is placed on the long axis of the target, the apex of the saddle is the point of

detonation.Made up of C4 ,thickness of the charge as well as size of the base and length are determined by the circumference of the TARGET.

The base of the charge is 1/2 the target circumference.The long axis of the charge is equal to the circumference of target.Finally the thickness of

the charge is 2/3in for targets up to 6in diameter,from 6-8in diameter thickness/up to 25in circumference is 1in of C4.(mild steel)

For targets in excess of 6in-8in diam. or made of high carbon/alloy steels the DIAMOND charge is reccomended.Shaped like a diamond it to is made up

of C4.Here again the long axis is = to circumference and the short axis is also 1/2 circumference.Thickness is

to be 2/3 in for a 15in circumference high carbon/ alloy steel detonated at the short axis points simultaneously.I suppose one would have to

extrapolate thickness to 1in for a target 6in diameter-larger

Rather than placed on the long axis as the saddle charge. T

The diamond charge is wrapped around the billet then detonated simultaneously at the short axis points.

This FM is a wealth of demolition info I think these likely less well known shaped charges are equally fascinating although I know even less about

how they function than an EFP or CSC .

PS; Im taking a leap that if the design of the shaped charge is less well known that qualifies them as an unconventional shaped charge.If Im wrong in

that assumption or if its felt that what Im derscribing doesnt qualify as a shaped charge I disagree.Regards Please excuse the many revisions I was attempting to make the post decipherable. Please excuse the many revisions I was attempting to make the post decipherable.

[Edited on 6-1-2011 by grndpndr]

[Edited on 6-1-2011 by grndpndr]

[Edited on 6-1-2011 by grndpndr]

[Edited on 6-1-2011 by grndpndr]

|

|

|

grndpndr

National Hazard

Posts: 508

Registered: 9-7-2006

Member Is Offline

Mood: No Mood

|

|

Little more 'unconventional'.

'Project Orion'," shaped charge fusion boosted fission explosive" designed for the lift off stage Of the 'Starship'

God help those of us left on earth.An estimated 800 nuclear devices would be required to reach low earth orbit IIRC the articles specifics.Fallout

anyone?

[Edited on 6-1-2011 by grndpndr]

[Edited on 6-1-2011 by grndpndr]

|

|

|

gnitseretni

Hazard to Others

Posts: 282

Registered: 5-1-2007

Location: Colombia

Member Is Offline

Mood: No Mood

|

|

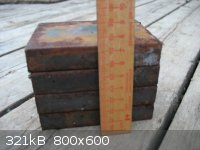

Finally got to try one of my liners. CD: 2 inch. Charge: 350g PETN plasticized with 10% by weight Propylene Glycol. (Wanted to use PGDN but ran out of time)

3 blocks of steel welded together, each 1-1/4" thick, so a total of 3-3/4". (looks more in the pic, but it's not)

All 3 blocks were penetrated but the carrot plugged the hole in the last one.

Here are some pics...

Blocks stacked together:

Direct link: http://img831.imageshack.us/img831/8258/sl731117.jpg

Entry holes:

Direct link: http://img20.imageshack.us/img20/2046/sl731118.jpg

Exit holes:

Direct link: http://img714.imageshack.us/img714/1193/sl731120.jpg

EDIT: forgot the short video http://www.youtube.com/watch?v=_oDSM_q_3BE

Video does NOT do it justice but thought I'd add it anyway.

[Edited on 15-2-2011 by gnitseretni]

[Edited on 16-2-2011 by gnitseretni]

|

|

|

grndpndr

National Hazard

Posts: 508

Registered: 9-7-2006

Member Is Offline

Mood: No Mood

|

|

Most Impressive post ive seen in some time.3.75 in mild steel penetration by a 2x CD

Conical Shaped Charge and judging by the exit holes they had some more penetrating to do.And the cones manufactured by plating! Great

stuff,repeatable-consistent

cones from, #1 -#50!

That in itself is an accomplishment worth note all in itself.From spinning inconsistent nonrepeatable cones( no disrespect intended) to nearly cookie

cutter cone manufacture.

What was the foremost block to repeatable CSC's?!Consistent cones!

3.75-4in+ mild steel penetration.And from the looks of the exit holes they were far from done penetrating.The exit holes after penetrating the near

4in were nearly the size of

the initial entrance holes the sure didnt look like the last hurrah for that charge.

If we assume at least 4in mild steel penetration from the 2CD SC a rough comparison

between the penetration ratios are 2/3 for armor steel versus mild steel thats roughly 2.5 in+ rolled homogenous armored steel /4in mild steel.VERY

respectable performance from improvised munitions as complex as shaped charges.

Many yrs and long time since AXTs 2in glass csc/2in mild steel penetration. I began to wonder if anyone would top with a copper SC. Its been several

yrs w/o competition it seemed and now performance has been doubled.

Just a few specifics if I can ask about details?Material the body of the SC was constructed from.Approximate thickness(ML) of the 2in diam

CSC?Anything different in terms of accepted construction specs such accepted stds as head hieght,stand off.Strong confinement? Again what i think to

be an excellent effort,I hope others will take up the challenge!Hats off to you gnitsernetni!!

|

|

|

gnitseretni

Hazard to Others

Posts: 282

Registered: 5-1-2007

Location: Colombia

Member Is Offline

Mood: No Mood

|

|

Thanks grndpndr. I wish I had more of those blocks, because I too think it could have penetrated a bit more.

Container was PVC pipe. Standoff was about 3 inches. That's about it for specs. I know I didn't document it well, but that's because I wasn't planning

on sharing. Due to circumstances I have to put this hobby on the back burner again. So I quickly put together one more charge to get rid of my PETN

and be done with it. But at the last second I decided to take my camera with me after all. I promise I won't be this sloppy again

|

|

|

grndpndr

National Hazard

Posts: 508

Registered: 9-7-2006

Member Is Offline

Mood: No Mood

|

|

Dont worry the target plates speak volumes.

Do wish you had or could measure the liner thickness?

|

|

|

gnitseretni

Hazard to Others

Posts: 282

Registered: 5-1-2007

Location: Colombia

Member Is Offline

Mood: No Mood

|

|

I have another liner, I'll be sure to measure its thickness when I can make another charge.

Btw, I was a little surprised that a carrot had formed. I didn't think a carrot would form considering the way the liner was

manufactured.(electroformed) I thought it would be brittle, just like a liner made from compressed powder because basically electroforming is just

particles that build up on a form.

|

|

|

grndpndr

National Hazard

Posts: 508

Registered: 9-7-2006

Member Is Offline

Mood: No Mood

|

|

Another topic beyond my payrade but ill ask a friend who spent years in an electroplate shop, clues as to why the electroplate would behave as a

plate/casting might.I was under the impression in electroplating it was bonded on a molecular level rather than sintering which is heat and pressure

a mechanical bond.

Why the enormous pressure of the CSC doesnt make the sintered copper liner act as a plastic I dont have a clue.

If CSC's depended on a mallebale cones so much for glass CSC

liners.

[Edited on 20-2-2011 by grndpndr]

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

Just out of curiosity was the form for the cone, a fence post top? And have you made a (simple) record of the time in which a production cycle ran?

|

|

|

gnitseretni

Hazard to Others

Posts: 282

Registered: 5-1-2007

Location: Colombia

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by quicksilver  | | Just out of curiosity was the form for the cone, a fence post top? And have you made a (simple) record of the time in which a production cycle ran?

|

Yeah, fence post top from Ace Hardware, they call them Bullet Caps. That liner (and yours) took 3 days of plating. Mine was almost twice as thick as

yours because less of the post top was submerged in the plating solution, which decreased voltage, but because current density stayed the same it

plated at a faster rate.

|

|

|

grndpndr

National Hazard

Posts: 508

Registered: 9-7-2006

Member Is Offline

Mood: No Mood

|

|

This is a fascinating leap for CSC and EFP's.Similar to a hobbyist what interchangeable parts were to manufacturers.

Theres an awful lot of variation possible on the theme, something unavailable not long ago.Along with precision repeatability one less factor to

consider in a design if you can assume your CSC liner was identical to the last.Whats that worth to experimetation?

Repeatable, easily made cones fired into target plates professionally arranged as is possible to identify and repeat results.I cant find any real

fault with the concept, seems equally as useful in making single finned long rod hard tgt EFP's to multiple efps.

Unfortunately it would seem gang type forms could be crafted

easily so that availability of platters/CSC's could be to common to discuss any more on natl news

Seems exceedingly simple process easily available materials

and if a custom shaped EFP-CSC design were contemplated

the aluminum Dies could be easily made on a simple lathe.

Actually looks like a nightmare for both homeland security and our troops in afghanistan Iran.no longer are machine shops with lathes-punch presses

required but tupperware,copper tubing etc, electrical power supply and a suitable aluminum form.

Its one heck of a good idea it seems to me if your lacking

several thousand dollar lathes and several hundred thousand dollars worth of hydraulic punch presses.

[Edited on 11-3-2011 by grndpndr]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I have been using the electroforming method to make some copper cones lately. I was having trouble finding suitable aluminum forms, so I got a few

short lengths of aluminum round stock from a machine shop in various diameters, then me and a friend turned the cones on a lathe. I will get to the

results of this later, but just for fun I wanted to show the results of using a brass candle holder as a liner.

Using nitro-genes's methods for making putty explosives from the thread PETN vs RDX as a general guide, I made putty, but with ETN instead of PETN. I

have been making this for a while actually. I used about 44g of this 85% ETN and 15% inerts plastic explosive.

The candle holder liner looked fairly symmetrical and uniform in thickness. The thickness of the liner was slightly more than the thickness of a dime,

or a little more than 1mm. The candle holder was definitely not a cone shape, maybe closer to a trumpet shape.(?) The liner was approximately 1 inch

in diameter.

The steel pipe that was used was from the frame of a swing or something I found at a scrap yard. It was convenient because the smaller diameter pipe

was just slightly smaller than the liner, and the larger pipe was just slighly larger. The liner could be locked between two pieces of the smaller

pipe with a short length of larger pipe over the join. I tacked the thing together with a brazing rod and an oxy-acetylene torch. I used bamboo

skewers as standoff sticks, trimmed to length. About 1.5 cone diameter standoff was used.

I got about 1 inch of penetration. Each steel piece in the picture is 3/4 inches thick. I piled up four pieces of the steel, (I was ambitious). I got

reasonable penetration I think even though I didn' t have the liner perfectly straight, (I didn't want to take it all apart again to straighten it).

From the picture with the tooth-pick in it, it is obvious that the jet went through at an angle. The jet also spit, you can see where parts of the jet

penetrated about 1/4" or so in several places, and the main hole is very large at first and after an inch of penetration is quite narrow. The top two

steel pieces, post blast, are shown in the bottom row of pictures. The second piece was only penetrated about a 1/4".

[Edited on 11-9-2011 by Hennig Brand]

|

|

|

| Pages:

1

..

29

30

31

32

33

..

68 |