ThatchemistKid

Hazard to Others

Posts: 132

Registered: 2-6-2010

Member Is Offline

|

|

Reduction of Vanillin via Zn/AcOH problem

Hello, I am new here and still an undergraduate so please excuse any ignorance. Currently I am attempting to reduce vanillin to vanillyl-alcohol and

have run into sort of an issue.

Ok, so down to business. The procedure I followed was a moderately modified version of one described on page 46 of Weygand and Hilgetag Preparative

Organic Chemistry.

Here is their procedure :

Here the preparation of 2-(l-naphthyl)-l-propanol304 will be described as an example of reduction by iron powder:

A mixture of 2-(l-naphthyl)propionaldehyde (83.5 g), acetic acid (300 ml), water (300 ml),and iron powder (200 g) is heated for 7 h on the steam-bath.

The solution is then filtered and

the filter-cake is washed with water and then with ether. The filtrate and wash-water are diluted with water and then extracted with ether. The oil

remaining after evaporation of the

ether is boiled with a solution of NaOH (15 g) in water (30 ml) and alcohol (50 ml) to cleave the acetate that has been formed. The alcohol is then

washed, dried in ethereal solution, and

distilled. 2-(l-Naphthyl)-l-propanol is obtained as a yellowish viscous oil of b.p. 144-147°/3 mm, in 78.5% yield (66.3 g).

The modifications I made were, first, I scaled down the reaction to only 5 grams of the 4-Hydroxy-3-methoxybenzaldehyde, 30 mls glacial acetic acid

and 18 grams zinc (all were scaled down to where they were still in the same molar ratios as described in the paper and a slight excess of glacial

acetic acid was then added. I also replaced Iron with Zinc, as the text had previously said that either could be used only changing the formation of

side products ( Iron demotes the formation of glycols which apparently aromatic aldehydes have a higher tendency to form.) Also i believe that both

metals were going to end up in the divalent state so I did not see to much of an issue in interchanging them (but this could have been out of

ignorance).

It should be noted that this was done at home.

Procedure: 5 grams (.032 moles) of 4-Hydroxy-3-methoxybenzaldehyde were weighed out and placed in a

125 ml erlenmeyer flask and dissolved in 30 mls (.52 moles) of glacial acetic acid that had been just freshly distilled from relatively dry sodium

acetate and sulfuric acid (drain cleaner sulfuric acid) the flask was placed on a magnetic stir plate and a teflon coated stir bar was dropped in.

Next 18.6 grams (.28 moles) of zinc powder were added to the flask and the stir plate was turned on. Then 10 mls of water were added to the mixture.

The reaction was allowed to proceed for 7 hours and then the reaction mixture was extracted with 30 mls of ether/heptane mix ( the ether heptane as im

sure many here are familiar with came from starter fluid, I could have made my own ether but I figured it was not worth the hassle and that this would

work out just fine). That ether extract was washed twice with 25 mls of a saturated bicarbonate solution, and here is where the issue occurred. As

soon as the bicarbonate solution hit the ether and then separated down to the bottom of the 250 ml separatory funnel a white crystalline solid formed

in the aqueous layer. upon shaking a lot of gas was evolved and the solid disappeared but the aqueous layer turned a redish pinkish purple color

(which I thought might be the glycol but I am really unsure.) The organic layer was then dried over calcium chloride for a few minutes and then I

proceeded to distill away the solvent (under a slight vacuum because i am impatient). After most of the solvent was distilled off an oily layer could

be seen at the bottom of the distillation flask. I took this oily layer along with the last mls of solvent and placed it in a 250 ml beaker to allow

the last bit of heptane to evaporate and the acetate ester of the product to solidify. (possibly the di-acetate if the OH on the aromatic ring

reacted). Next, since my interest was peaked I added about 50 mls of water to the remainder of what was in the 125 ml erlenmeyer flask and filtered

this away into the

250 ml separatory funnel. I washed the remaining zinc with ether/heptane and then extracted the water that was in the separatory funnel with 30mls of

ether/heptane ( included in that 30 mls was the ether/heptane used to wash the zinc.) After extraction the ether/heptane was washed twice with 25 mls

of the saturated bicarbonate solution to remove the excess acetic acid and lo and behold I ran into the same problem as before odd precipitate and

redish pink aqueous layer. The Organic layer was dried over calcium chloride and distilled and the product is currently still sitting in the still

pot. The yield does not look to be to high at all, on the order of about 1 gram once the ester is hydrolyzed and the product isolated. Theoretical

yield is 5.06 grams of vanillyl alcohol (so the estimated yield is about 20%)

here are a few pictures of the procedure (this is my first post so hopefully I can upload these correctly)

this is a picture of everything in general sitting in my in need of cleaning fumehood.

the starter fluid used just for reference if anyone is familiar with this brand

this is the unknown by product that is in the aqueous layer, it is a bit more red in reality. (does anyone have any idea what this is?)

here is a slightly blurry picture of the product, as you can see there is only a little over a ml in the beaker but it is beginning to form crystals

(I think I had an oiling out issue with the product)

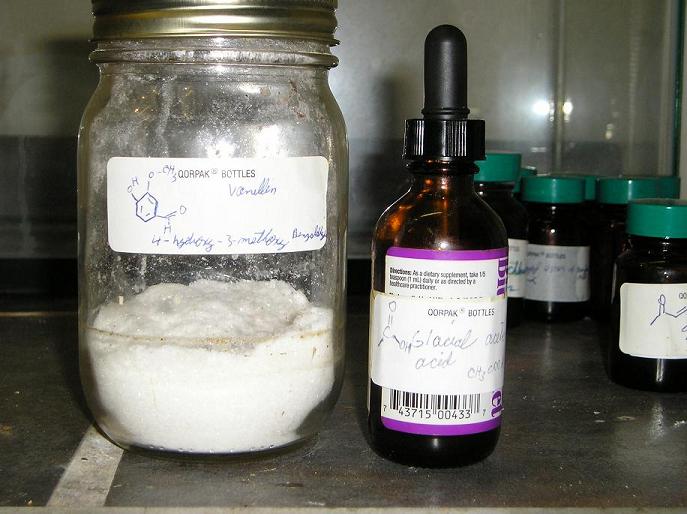

the containers for the vanillin and glacial acetic acid used.

the distillation of the solvent ( no water running through the condenser because I thought it was not needed.)

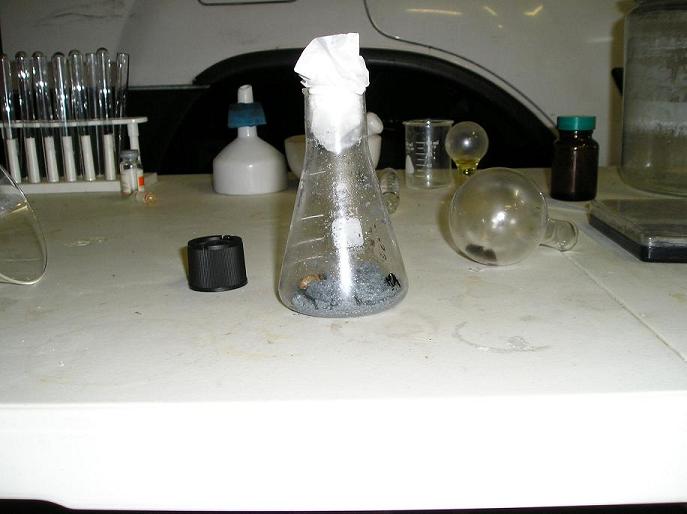

and finally just a picture of the zinc left over from the reaction.

suggestions for possible revisions and an explanation of what that the redish pink unknown might be, along with anything that might stab out

ignorance from my mind will be appreciated

There we go everything should be in order now

[Edited on 3-6-2010 by ThatchemistKid]

[Edited on 3-6-2010 by ThatchemistKid]

[Edited on 3-6-2010 by ThatchemistKid]

|

|

|

ThatchemistKid

Hazard to Others

Posts: 132

Registered: 2-6-2010

Member Is Offline

|

|

I will give the final results of the experiment once I have isolated the product and taken the melting point

|

|

|

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

Keep in mind that the phenol and methoxy moieties on the ring are going to make it significantly more polar and soluble in water than the

naphthyl-containing compound you are basing the procedure off of. In addition, you extracted with an ether/heptane mix which is even less polar than

the straight ether used in the original procedure.

The product may also co-distill with your solvent, but you'd have to check.

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

ThatchemistKid

Hazard to Others

Posts: 132

Registered: 2-6-2010

Member Is Offline

|

|

I had thought of the issue of higher water solubility ( especially when I was going to hydrolyze the acetate ester) but it turns out that

4-hydroxy-3-methoxybenzyl alcohol is soluble in hot water, which may rule out that issue. But considering that even when the reaction mixture was

diluted with 50 mls of water nothing crashed out makes me wonder a little.

Also the acetate ester formed is likely to be even less water soluble then the actual alcohol, no? and some product was isolated from the

ether/heptane.

Do you know of a slightly more polar solvent or solvent mix that could be used to extract the product?

|

|

|

Polverone

Now celebrating 21 years of madness

Posts: 3186

Registered: 19-5-2002

Location: The Sunny Pacific Northwest

Member Is Offline

Mood: Waiting for spring

|

|

I was curious if this route has been noted before.

I was able to find the reduction of vanillin to vanillyl alcohol with:

sodium amalgam

electrolysis (few details available)

borohydrides

hydrogen with platinum catalysts

living cell cultures (for that beloved "natural" claim on food & flavor ingredients)

Have you ever attempted this reduction by one of the documented methods? Do you have a reference sample of vanillyl alcohol that you might use to

practice/develop the extraction? It seems to me that combining an uncertain synthesis with an uncertain extraction may lead to more difficulty than

developing them separately.

A MP determination is a good check but may be rather time consuming to run for each reaction, assuming you wish to optimize this procedure or run it

repeatedly. If you could characterize the unhydrolyzed ester by TLC that could save some steps and time in checking each experiment.

I love to see that you're trying something new. I just want to be sure you can explore this idea without getting frustrated if it is more troublesome

than expected.

PGP Key and corresponding e-mail address

|

|

|

leu

Hazard to Others

Posts: 368

Registered: 13-10-2005

Member Is Offline

Mood: No Mood

|

|

It seems sodium borohydride is usually used for this reduction, these experiments might help

Attachment: GEMsID90.pdf (42kB)

This file has been downloaded 2703 times

Attachment: Chem333lab8.pdf (38kB)

This file has been downloaded 623 times

Chemistry is our Covalent Bond

|

|

|

ThatchemistKid

Hazard to Others

Posts: 132

Registered: 2-6-2010

Member Is Offline

|

|

To be honest this is my first time running this experiment, I have previously attempted to isolated vanillyl alcohol from a cannizzaro reaction and I

could use the product isolated from there to work on my extraction. Either way I am about to combine both bits of product and hydrolyze and see what

comes of it. I am very grateful for all the help it has been very enlightening  . .

The TLC Idea sounds great but first I have to figure out a way to do this at home, any suggestions? I suppose buying the TLC plates or a

Chromatography column would not be to much of a hassle.

Also, I do not have any sodium borohydride or I would have jumped on that idea immediately  . .

[Edited on 4-6-2010 by ThatchemistKid]

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Polverone  | ...

I was able to find the reduction of vanillin to vanillyl alcohol with:

sodium amalgam

electrolysis (few details available)

borohydrides

hydrogen with platinum catalysts

living cell cultures (for that beloved "natural" claim on food & flavor ingredients)

... |

Meerwein−Ponndorf−Oppenauer−Verley reduction? The traditional catalysts generally don't give good yield for benzaldehydes with

electron-releasing substitutes, but more recent works have had better results. NaBH4 is still a real good choice.

I agree that the water solubility might be a problem.

I believe that procedures for making your own TLC plates has been discussed here, and the large commercial plates can be cut to give a number of

smaller ones for reaction tracking.

Attachment: Meerwein_Ponndorf_Verley_reduction_of_carbonyl_compounds_catalysed_by_Mg_Al_hydrotalcite.pdf (29kB)

This file has been downloaded 1648 times

[Edited on 4-6-2010 by not_important]

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

Good to finally see some young enthusiasts doing something interesting. But, there are a few issues first. As I see, most was already discussed...

Without a reference in support of your idea that using such a reduction system gives vanillyl alcohol or its acetate, the product(s) could actually be

something else (pinacol coupling, reduction to cresol, etc.). Also, your reaction work up was not proper for the reasons mostly already discussed. The

only references for the use of zinc in the reduction of vanillin that I could find were about the reduction all the way to creosol via the Clemenssen

reduction (Zn-Hg):

Journal of the American Chemical Society, 53, 19311924-1928; DOI: 10.1021/ja01356a047

Drug Development Research, 60, 2003, 186-195; DOI: 10.1002/ddr.10281

Tetrahedron, 62, 2006, 2892-2900; (only "Zn, concd HCl, EtOH, reflux, 3 h, 80%" and lacking any further experimental)

DOI:10.1016/j.tet.2006.01.021

Organic Syntheses, 33, p.17 (1953). (wrong isomers are depicted on the scheme, just ignore that)

Creosol is an another interesting substrate for testing reactions on phenols and it is not troublesome for the isolation from aqueous solutions

(though being a liquid it requires vacuum distillation for purification). Maybe you should nevertheless try its synthesis first, to gain some

practical skills first.

Otherwise I could find no example where zinc dissolving reactions would give vanillyl alcohol/ester from vanillin (or the corresponding reduction of

p-hydroxybenzaldehyde). You might think that using plain zinc, nonactivated by Hg, and a mild acid like acetic acid would stop the reduction at the

vanillyl alcohol/ester stage, but vanillin is not just any benzaldehyde substrate and simple generalization of reactions is no good in its case. The

first reduction product is a para-hydroxybenzyl alcohol/ester derivative and these have their own peculiar chemistry (see for example this thread).

| Quote: | | The reaction was allowed to proceed for 7 hours and then the reaction mixture was extracted with 30 mls of ether/heptane mix ( the ether heptane as

im sure many here are familiar with came from starter fluid, I could have made my own ether but I figured it was not worth the hassle and that this

would work out just fine). |

First of all you need to dilute the reaction mixture with about four times its volume of water. This assures that the cosolvent (acetic acid in this

case) does not interfere too much with the partition of the inorganic salts and organic products. Then you need to use a proper solvent for the

extraction. A heptane/diethyl ether mixture is not going to efficiently extract a compound like vanillyl alcohol which has a calculated

logP(octanol/H2O) of 0.94 or its acetate ester (calc logP = 1.17). It would take ethyl acetate to extract them, and preferably with a triple

extraction from the diluted reaction mixture (due to the presence of the cosolvent). It would however extract some of the creosol (calc logP = 2) or

practically all of it from a properly diluted reaction mixture. (see this thread for more info)

| Quote: | | That ether extract was washed twice with 25 mls of a saturated bicarbonate solution, and here is where the issue occurred. As soon as the bicarbonate

solution hit the ether and then separated down to the bottom of the 250 ml separatory funnel a white crystalline solid formed in the aqueous layer.

upon shaking a lot of gas was evolved and the solid disappeared but the aqueous layer turned a redish pinkish purple color (which I thought might be

the glycol but I am really unsure.) |

Zinc hydroxide and carbonate are insoluble in water so what you saw was probably precipitation of some of these salts being carried with the extract

(drops of aqueous phase remaining in the funnel). This is why it is good to have a wash with water in between (provided you use ethyl acetate or some

other proper extraction solvent). Gas evolving while the extracted acetic acid is being neutralized with NaHCO3(aq) is normal (CO2). You should take

care while washing extracts containing acids in a separatory funnel using (bi)carbonates, because often a lot of CO2 and foam evolves which commonly

leads to spill overs and flying stoppers. NaHCO3(aq) should be initially added in small portions and with swirling the mixture before actually

tapering and shaking the funnel (to prevent potential pressure build up). Colorization of the extract during pH changes is normal. It usually means

little to nothing (many tarry side products have long conjugations with a acidic/basic fuctional group and therefore colorize on pH change, but this

occurs even if they are present in ppm amounts). Additionally, some phenols, even if pure, form pinkish or yellowish solutions of their corresponding

phenoxides. Some phenoxides are very intensively coloured even if the corresponding phenols are completely colourless (think of phenolphthalein as an

example).

| Quote: | | The organic layer was then dried over calcium chloride for a few minutes and then I proceeded to distill away the solvent (under a slight vacuum

because i am impatient). After most of the solvent was distilled off an oily layer could be seen at the bottom of the distillation flask. I took this

oily layer along with the last mls of solvent and placed it in a 250 ml beaker to allow the last bit of heptane to evaporate and the acetate ester of

the product to solidify. (possibly the di-acetate if the OH on the aromatic ring reacted). |

Never use CaCl2 for drying anything with even slightly basic or chelating functional groups (alcohols, phenols, amines, anilines, amides,

heterocycles…). CaCl2 will complex a lot of compounds. MgSO4 is much, much more acceptable, though it also exceptionally chelates with some

organics. Na2SO4 is most general drying reagent and it will not react with any organic as far as I can think of.

Phenolic groups cannot esterify under such conditions.

In addition to the Cannizzaro reaction, alternative OTC reagents for this reduction might be sodium dithionite (aka sodium hydrosulfite) or thiourea dioxide. However, these are not backed up by references for vanillin specifically. Another possible approach is the reduction using

Urushibara conditions: DOI:10.1016/S0040-4020(01)82402-9, DOI:10.1016/S0040-4039(01)89023-7

Buying a pack of analytical TLC plates (some standard ones with fluroscein impregnated silicagel on aluminium foil) is an excelent investment if you

want to do experiments in organic synthesis. They are a necessity if you want to try out new syntheses. Buying a 254nm UV lamp also help immensely,

though visualization of TLC plates can also be achieved using visualization reagents (a KMnO4/K2CO3 solution is one pretty general one for all kind of

compounds). Use the search engine for more info.

PS: See also J. Chem. Educ., 69, 1992, , A43, DOI: 10.1021/ed069pA43. For a yeast fermentation based reduction see: J. Chem. Educ.,70

1993, p A155, DOI: 10.1021/ed070pA155.

Edit: What is the reference for the Cannizzaro reaction with vanillin? According to DOI: 10.1021/ja01207a025 and particularly DOI:

10.1021/jo01165a011, vanillin does not give any vanillyl alcohol under the Cannizzaro reaction conditions. The authors were able to obtain vanillyl

alcohol only when a several-fold excess of formaldehyde was used in a silver catalysed cross-Cannizzaro reaction, otherwise only vanillic acid and

polymerised vanillyl alcohol formed.

[Edited on 5/6/2010 by Nicodem]

…there is a human touch of the cultist “believer” in every theorist that he must struggle against as being

unworthy of the scientist. Some of the greatest men of science have publicly repudiated a theory which earlier they hotly defended. In this lies their

scientific temper, not in the scientific defense of the theory. - Weston La Barre (Ghost Dance, 1972)

Read the The ScienceMadness Guidelines!

|

|

|

ThatchemistKid

Hazard to Others

Posts: 132

Registered: 2-6-2010

Member Is Offline

|

|

WOW!,... Im going to go study some more because it seem to me that I am way behind !!, I knew about the calcium chloride issue but i was under the

impression that it was more of an issue with smaller alcohols.

And the suggestion that the substrate came out in the aqueous phase was spot on, but now i am not sure as to the identity of the substrate.. But will

still try to isolate and attempt to characterize via NMR and IR.

The cannizaro reaction problem with vanillin explains quite a bit of issues that i had with purification!(although I had just recently thought of

doing a cross Cannizzaro with formaldehyde with vanillin, I did not explicitly know that cross Cannizzaro reactions existed at the time that I tried

it, I just had assumed that it was a possibility for them to work.)

And thanks for all the help!

|

|

|

|