| Pages:

1

2 |

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Ceric ammonium nitrate- uses and synthesis

The Ce(IV) ion is a powerful oxidiser in aqueous solution, stronger than chlorine, and capable of very interesting reactions, especially in organic

chemistry.

When its oxidising properties are to be used in preparations, it is most commonly employed as the salt ceric ammonium nitrate, or short CAN:

(NH4)2Ce(NO3)6

I think that this reagent has received much less attention among amateur chemists than it deserves.

The Organikum (22nd edition) has a preparation of p-tolualdehyde (p-methylbenzaldehyde) from p-xylene by oxidation of one of the methyl groups to the

aldehyde group with CAN.

A yield of 68% is claimed, which is very good for such an aldehyde preparation that easily can result in overoxidation to the acid when other

oxidisers are used.

This preparation is very simple and straightforward: 0,4 mol CAN in 200ml 50% aqueous acetic acid is heated with 0,1 mol p-xylene on the boiling water

bath under strong stirring and reflux for 20 min (soln becomes light yellow). After cooling down it is extracted thrice with ether, the pooled

extracts washed with Na2CO3 soln to remove acidic byproducts, dried with MgSO4 and distilled to separate solvent, product, and impurities.

I think this could work just as well for the oxidation of toluene to benzaldehyde. Isnt that something a lot of people here always want to do?

It also oxidises benzylic alcohols to the aldehyde, and phenols to quinones.

The wikipedia page on CAN is very informative:

http://en.wikipedia.org/wiki/Ammonium_cerium(IV)_nitrate

This useful chemical is, however, quite expensive (500g 109€ from Aldrich, cheapest grade) from most chemical suppliers, far more so than the other

well-known oxidants like permanganate and dichromate.

A method for its preparation at home would be something worth investigating.

A cheap source for cerium compounds exists: ceric oxide, CeO2, is used for polishing gems and glass and is cheap in this form.

Be sure to get the white quality, this is essentially pure CeO2.

I will buy 200g of such CeO2 soon.

As its use for polishing suggests, this oxide is strongly calcined (so that it consists of hard, abrasive crytals) and thus unreactive, just like

calcined alpha-Al2O3.

It does not dissolve in acids unless a reducing agent is present, according to Brauer, and then it goes in solution as the Ce(III) ion.

Wikipedia says that a solution of the Ce(NO3)6(2-) ion can be obtained by dissolving Ce2O3 in conc HNO3 (oxidation of the Ce(III) takes place)- this

has to be boiled according to Brauer.

After evaporation of most of the HNO3, ammonium nitrate solution can be added to form the salt, and this crystallized after repeated evaporation with

HNO3 (dont ask why, Brauer says it).

Brauer gives a rather tedious method for CeO2 dissolution using hydroquinone which gives problems because the benzoquinone byproduct must be gotten

rid of before further processing. A different and less problematic reducing agent seems to be necessary- I'd like to try formic acid.

Brauer further gives a procedure for crystallizing the CAN and an ether extraction of ceric nitrate from CAN in 6N HNO3 for complete separation from

other rare earth elements- not necessary for us if the starting material is pure.

We can stop after the crystallization of CAN from the HNO3 solution after addition of AN and repeated evaporation with HNO3.

Obviously the yield will be far from quantitative due to CANs high solubility (mother liquor can be further boiled down once to yield a second crop),

but the Ce values can always be recycled from the mother liquors (and spent CAN during further use in synthesis) simply by diluting with water and

adding oxalic acid while hot- the oxalates of the trivalent rare earths are all sparingly soluble, and the oxalic acid acts as the reducing agent as

well.

If someone wants to do this, read the chapter "Pure cerium compounds" in Brauer, it essentially contains a preparation of CAN but not an optimal one.

When I receive my CeO2 I will try this out and report here.

Has anyone here done preparative work with Ce(IV) compounds or knows about them? Woelen?

Any comments or tips towards synthesis of CAN?

[Edited on 20-11-2007 by garage chemist]

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

Oh! No! Please don't use CAN as an abbreviation for this chemical!

CAN is the pretty much standard abbreviation for Calcium-Ammonium Nitrate, a fertilizer which is a blend of about 20% CaCO3 and 80% Ammonium Nitrate.

Wouldn't CeAN or CEAN be more appropriate!

Regards, Xenoid

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Ethanol or H2O2 have been used as reducing agents when dissolving CeO2 in HCl or H2SO4, and also to reduce slightly acid solutions of Ce(IV).

Frederick Smith's Cerate Oxidimetry starts with a low grade of CeO2, 45% or 60% ceric oxide. These grades dissolve in HNO3, the 45% with

evolution of heat. I suspect that these grades are no longer obtainable, or if so only in box car quantities.

I'll dig the pamphlet out and type in the CAN production from it.

CAN is nearly insoluble in concentrated HNO3, while the REE(III) nitrates are somewhat soluble. Thorium, as the nitrate, would be the main

contaminate, these days thorium doesn't really show up in REE products.

|

|

|

woelen

Super Administrator

Posts: 8012

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

I have not really done preparative work with cerium salts, but I have some experience with the cerium(III) and (IV) ions.

Cerium(III) is amazingly hard to get oxidized to cerium(IV). You need potent oxidizers (e.g. hot persulphate) in order to get it oxidized. Cerium(IV)

oxide, CeO2, even the freshly precipitated oxide/hydroxide only very slowly dissolves in acids, giving a deep yellow solution.

I am afraid that the dissolving of calcined CeO2 will be VERY hard. CeO2 is fairly cheap though.

http://cgi.ebay.nl/CERIUM-OXIDE-Ce-99-8-250g-Very-high-quali...

I have good experience with this seller.

|

|

|

YT2095

International Hazard

Posts: 1091

Registered: 31-5-2003

Location: Just left of Europe and down a bit.

Member Is Offline

Mood: within Nominal Parameters

|

|

just a quick question, since quite a few of the rare earth metals share a similar chemistry, would it possible to use Samarium instead?

I have some of that, but the only Cerium I have is in the form of an alloy in Lighter flints.

\"In a world full of wonders mankind has managed to invent boredom\" - Death

Twinkies don\'t have a shelf life. They have a half-life! -Caine (a friend of mine)

|

|

|

yan123

Harmless

Posts: 5

Registered: 4-10-2007

Location: china

Member Is Offline

Mood: No Mood

|

|

generally, CAN is considered as cerium ammonoum nitrate, Chemiscal reviews has a paper talk about CAN (cerium ammonoum nitrate) in 2007.

| Quote: | Originally posted by Xenoid

Oh! No! Please don't use CAN as an abbreviation for this chemical!

CAN is the pretty much standard abbreviation for Calcium-Ammonium Nitrate, a fertilizer which is a blend of about 20% CaCO3 and 80% Ammonium Nitrate.

Wouldn't CeAN or CEAN be more appropriate!

Regards, Xenoid |

i am not for you to cherish.

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Xenoid: I think we should always use the proper term in a thread at least once before we use the acronym. I also wouldnt like it if everyone were

throwing around acronyms for chemicals that nobody but experts in a spceific field know about.

I always first explain the acronym (except in obvious cases, like THF or DMF), then I use it for the rest of the thread.

It should also mostly be obvious from the context what CAN would stand for- when people are talking about oxidation of methyl groups or alcohols with

CAN, then one can be sure that it isnt a nitrate fertilizer they are talking about.

| Quote: |

CAN is nearly insoluble in concentrated HNO3, while the REE(III) nitrates are somewhat soluble. Thorium, as the nitrate, would be the main

contaminate, these days thorium doesn't really show up in REE products. |

Thats great to hear, that would be a huge advantage if it is true. But then why does Brauer talk about concentration of the mother liquor to get more

crystals? Maybe the HNO3 isnt so concentrated at that stage of the procedure...

I'll have to see myself.

It would be really nice if you could post the article you were speaking of, but the white, pure CeO2 is the only grade that I can get. Nobody seems to

use impure rare earth compounds any more.

Samarium does not occur in tetravalent form.

The lanthanides that can occur in tetravalent form are Ce and Tb, and to a very limited extent (dont really know what is meant by this- maybe very

unstable?) Pr and Nd.

Of these, only Ce(IV) is metastable in water, the other ones all oxidise water to oxygen and therefore have no aqueous chemistry.

Ce is the most abundant rare earth metal, and by far the easiest one to obtain pure- oxidise it to Ce(IV) and adjust the pH so that hydrated CeO2

precipitates while all other lanthanides stay in solution. Or follow Brauers method with ether extraction of ceric nitrate.

Similar with Eu, which can be reduced to the divalent state and precipitated as the sulfate.

The other rare earths are more difficult to separate.

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

A cheap source of lower purity CeO2 is used as a glass polishing material. Mine is pink/salmon color. Try a shop that cuts and installs plate glass,

or their suppliers. Boiling with SO2 solution in water helps SnO2 dissolve in acids, maybe it would have the same effect on CeO2?

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Actually it is fairly easy to take Ce(III) to Ce(IV). Simply make a solution of a Ce(III) salt alkalike, and allow it access to air for awhile. The

Ce(OH)3 originally formed will darken to a red-orange, then change to a yellow as increasing amounts if the cerium are oxidised to the 4+ state. To

do it quickly, added H2O2 and then bring to a boil.

Praseodymium also goes into a higher oxidation state, but it forms mixed valence oxides and is difficult to get into any single pure state other than

3+. It may help with the dissolution of ceric oxide by shuttling between oxidation states, which helps do the same to cerium. However the physical

state of the oxide is important too, the low grade oxides used in the older preparations were likely ignited at a fairly low temperature and intended

as a source of the REE rather than as an end product like polishing powder.

I've had a range of difficulty in dissolving CeO2 from various sources. Some would go into solution in constant boiling HCl pretty nicely, others

took prolonged treatment with acid and ethanol, one batch took long boiling with concentrated H2SO4. And one !@#$%^&*( bag wouldn't dissolve in

any acid treatment, I ended up lining a large crucible with a cm or so of the oxide, then filling the center with a mix of the oxide and sodium

carbonate, fusing the mix, and then dissolving that in HCl.

I'll try to get access to a scanner in the morning to get those couple of pages in.

|

|

|

DeAdFX

Hazard to Others

Posts: 339

Registered: 1-7-2005

Location: Brothel

Member Is Offline

Mood: @%&$ing hardcore baby

|

|

Would molten Ammonium nitrate + Cerium (IV) or (III) oxide be sufficient to form the double nitrate salt? I remember there was a discussion here

about using metal carbonates or oxides and ammonium nitrate to produce the corresponding metallic nitrate?

|

|

|

YT2095

International Hazard

Posts: 1091

Registered: 31-5-2003

Location: Just left of Europe and down a bit.

Member Is Offline

Mood: within Nominal Parameters

|

|

| Quote: | Originally posted by garage chemist

Samarium does not occur in tetravalent form.

The lanthanides that can occur in tetravalent form are Ce and Tb, and to a very limited extent (dont really know what is meant by this- maybe very

unstable?) Pr and Nd.

Of these, only Ce(IV) is metastable in water, the other ones all oxidise water to oxygen and therefore have no aqueous chemistry.

|

Thank You

\"In a world full of wonders mankind has managed to invent boredom\" - Death

Twinkies don\'t have a shelf life. They have a half-life! -Caine (a friend of mine)

|

|

|

JohnWW

International Hazard

Posts: 2849

Registered: 27-7-2004

Location: New Zealand

Member Is Offline

Mood: No Mood

|

|

Probably the cleanest way to oxidize Ce(III) to Ce(IV) in solution would be by electrolysis. In the solid state, finely divided Ce2O3 oxidizes to CeO2

on heating in air.

Of the rare-earth metals that exhibit the +4 oxidation state, only Ce(IV) is stable enough to exist in solution, being highly complexed because of

its charge. Apart from CeO2 and salts of oxy-anions, the only other compound of it is CeF4 (and possibly oxyfluorides). The only other rare earths

that stably exhibit the +4 oxidation states are Pr, Tb, and possibly Nd, although only as the non-stoichiometric solid oxides, Pr6O11 and Tb4O7,

obtained by pyrolysis in air of the soluble salts as which they are isolated by ion-exchange chromatography. They are reduced to the +3 state with

evolution of oxygen if dissolved in acids. (It is not certain what the composition of the higher oxide of Nd is, or whether it has been characterized

at all).

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

OK, attacked is the basic prep pages and the cover of the pamphlet I was referring to earlier. I skipped the electrolytic ones, they take platinum

electrodes and are more for analytical grade.

There's a table in there that shows one run where they went for 3 crops of CAN, although the text doesn't mention concentrating the mother liquor. The

first crop was 3/5 or more of the cerium, purity of the CAN was 99,4%. The second crop was less than 1/5 of the Ce with a purity of 98,8%, the third

was smaller at 90% purity. So a second crop may be worth doing, but past that you may be better hitting it with base to recover Ce as the hydroxide.

Under alkaline conditions, H2O2 or air will oxidise Ce(III) to Ce(IV), the resulting Ce(OH)4 can be dissolved in acids to get the ceric salt. This is

as clean as electrolysis, and doesn't take expensive electrodes.

Note that NaOCl bleach will precipitate Ce(OH)4 from a solution of a Ce(III) salt. The hydroxide would need to be washed clean of Na and Cl ions,

although the dissolution in nitric acid will take care of the chloride and a trace of sodium isn't likely to be important in many applications.

Attachment: CAN.zip (579kB)

This file has been downloaded 1329 times

|

|

|

NADPH

Harmless

Posts: 11

Registered: 1-1-2010

Member Is Offline

Mood: No Mood

|

|

I tried to make (NH4)2Ce(NO3)6 all the way from ferrocerium rod.

First I dissolved about one third of huge ferrocerium rod in HCl. Reaction was quite violent (lot more violent than Nd2Fe14B magnets with HCl) and

huge amount of H2 gas and heat was liberated. Also there was strong unpleasant smell. So I decided to seal reaction flask with stopper conected to

rubber tubing to lead the gas far away and out through window (cheap alternative to fume hood). I left reaction overnight and then most of ferrocerium

was dissolved. Then I diluted reaction with distilled water and filtrated off all undissolved particles until solution was clear.

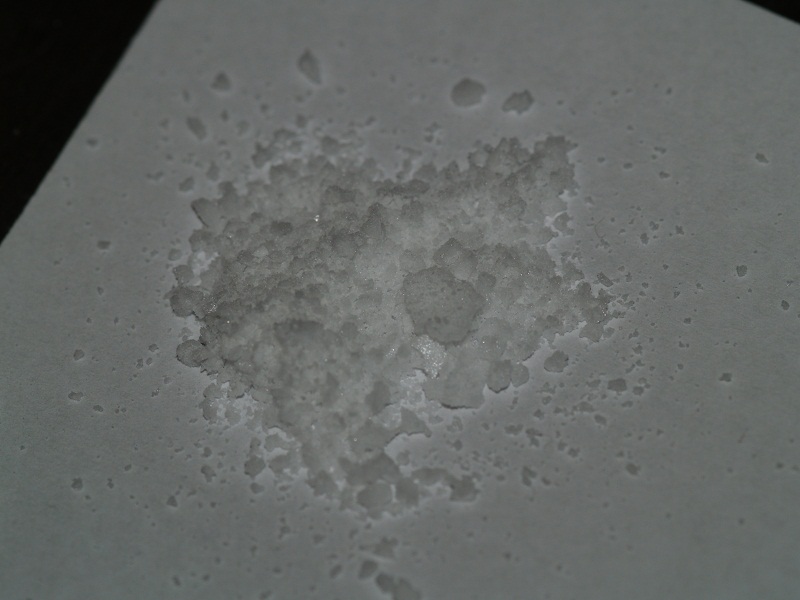

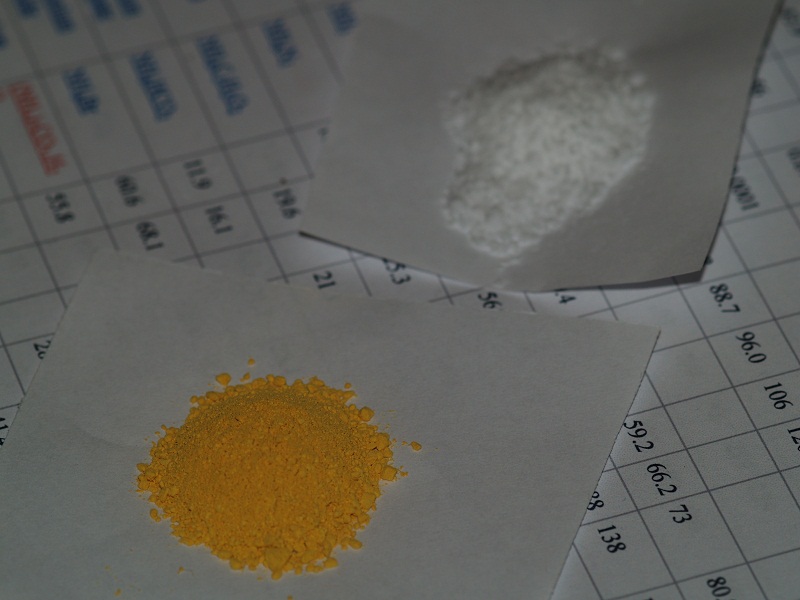

Next I purified Ce(III) by precipitating cerium (III) sulfate with concentrated solution of sodium bisulfate (of course sodium sulfate works as well

but bisulfate was only thing I had at the moment). Greenish Fe(III) was left in solution but white Ce (III) sulfate precipitated. I filtrated cerium

(III) sulfate and washed few times with boilig water. Dried it in oven @120˚C.

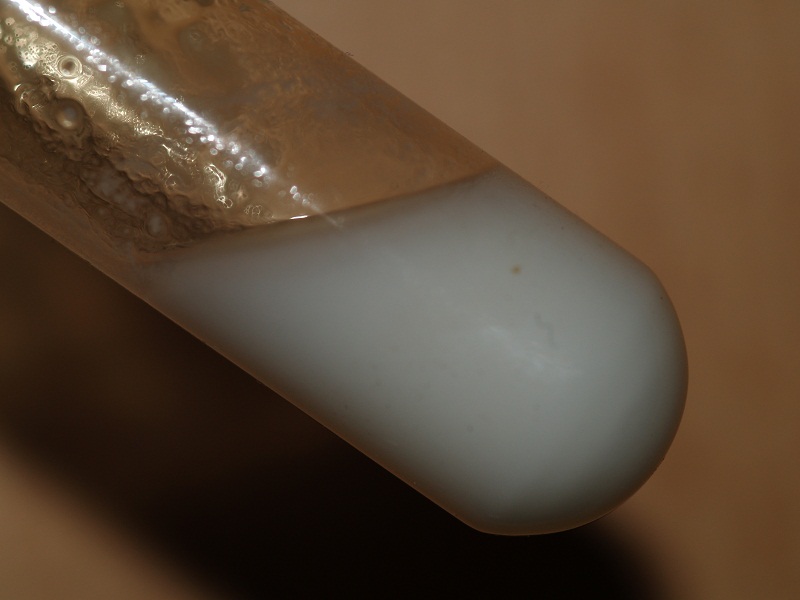

Then I converted all the Ce (III) sulfate to Ce (IV) hydroxide by mixing it with hot Na(OH) solution and adding H2O2 to oxidize Ce(III) to Ce(IV).

Before adding H2O2 I cooled reaction in ice bath but anyway H2O2 reacted quite virgously and after I dropwise added few mililiters of H2O2 colour

changed to yellow (fine emulsion of Ce (IV) hydroxide after shaking) but most Ce (III) hydroxide was still unreacted as yellowish white clumps. Since

H2O2 is not cheap, I added bleach (5% NaClO) instead. After few minutes of virgous shaking all clumps transformed to fine yellow emulsion which slowly

settled down. Left ir overnight, filtrated and washed 4 times with distilled water and 2 times with acetone. After drying I got few grams of fine

yellow powder of Ce(OH)4 (hydrate?)

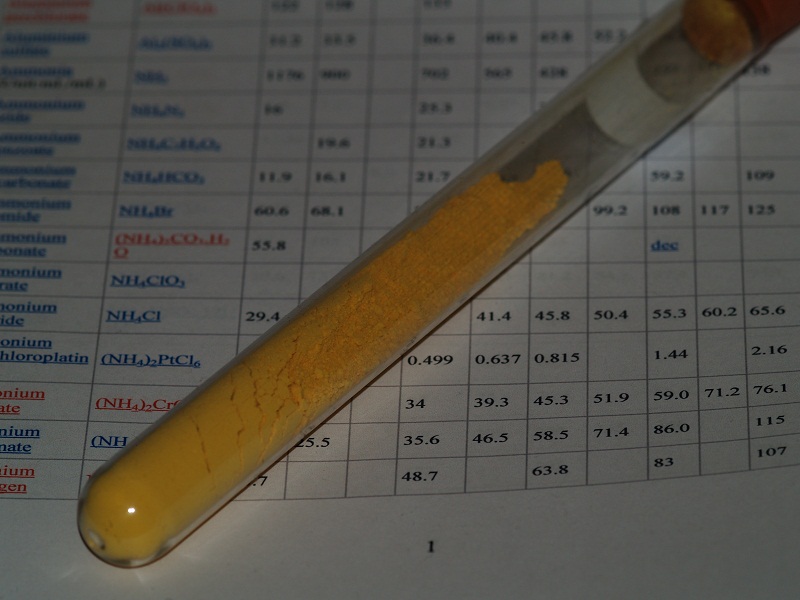

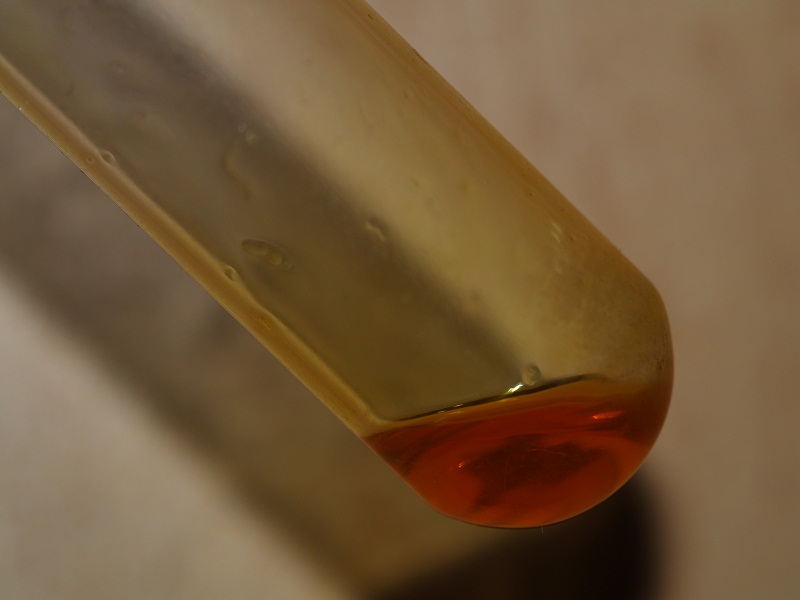

As it was quite expensive to make, first I tried to make ceric ammonium nitrate (CAN) in small scale. I weighted 0.5 grams of Ce(OH)4 (0.0024 mol) and

converted it to CeO2 by heating in test tube with butane torch until no more water was evolved.

After heating I got 0.36 grams of CeO2 (0.0021 mol).

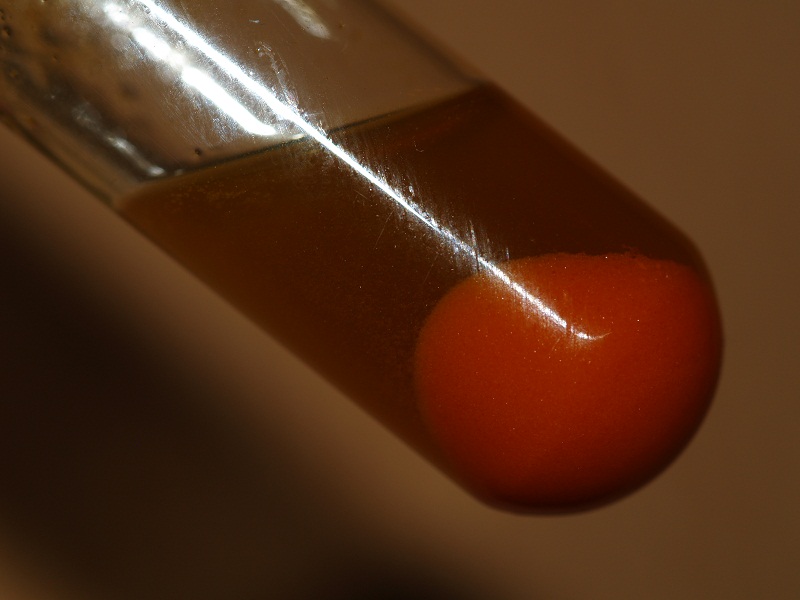

Next I heated stoichiometric amount of ~14M HNO3 (0.9 ml) and then added CeO2. It reacted virgously but lot of CeO2 remained undissolved.

I heated mixture and added more HNO3 dropwise (~0.5ml) until most of CeO2 dissolved.

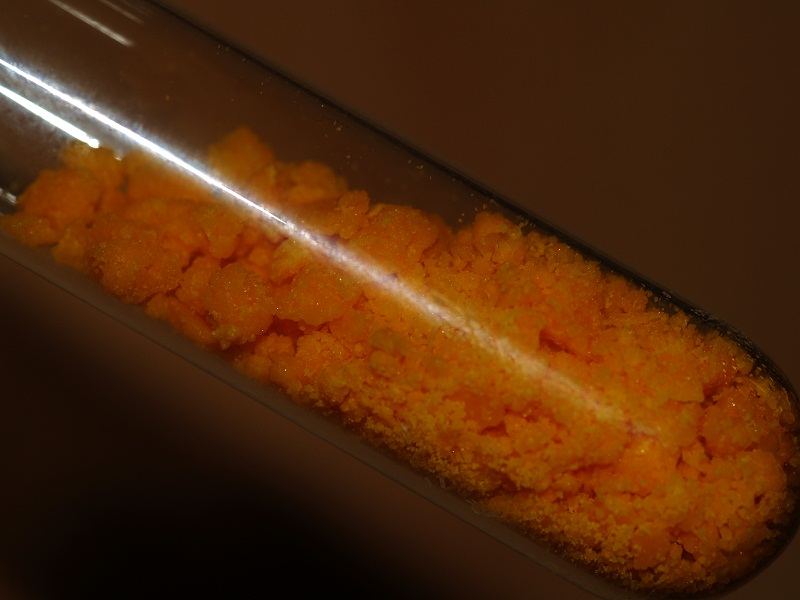

As a result I got cherry red solution which I transferred to fresh tube to get rid of undissolved particles (after settling them down for few

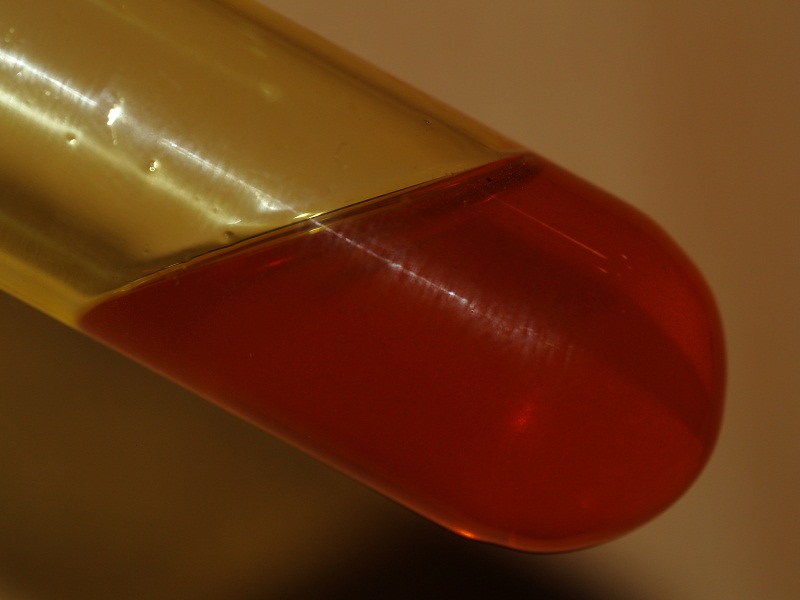

minutes). Then heated it and added stoichiometric amount of NH4NO3 (0.34 g).

Solutions colour changed from cherry red to orange and orange precipitate formed instantly.

As the colour is exactly as it should be (http://en.wikipedia.org/wiki/File:Ceric_ammonium_nitrate.jpg) I assume orange precipitate is pure (NH4)2Ce(NO3)6

Sorry for my English. I hope you can understand what I wrote.

|

|

|

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

Wow, very nice of it indeed CAN! This is a nice way to make this material, although it is not THAT expensive when you can buy it (about 1 euro per 6

grams). You are sure that all CeO2 dissolved?

But why did you heat the hydroxide to make the oxide? You had a good chance that the oxide would be unreactive, and hydroxides are generally more

reactive.

|

|

|

NADPH

Harmless

Posts: 11

Registered: 1-1-2010

Member Is Offline

Mood: No Mood

|

|

Almost all CeO2 dissolved. After heating only small pellet of dark brown material remained.

I was not sure if Ce(OH)4 was hydrated or not. An I thought that more CAN will precipitate out if I will get rid of as much water as possible. That is

why I calcined my Ce(OH)4

[Edited on 13-2-2010 by NADPH]

|

|

|

bbartlog

International Hazard

Posts: 1139

Registered: 27-8-2009

Location: Unmoored in time

Member Is Offline

Mood: No Mood

|

|

Nice work! just to nitpick though -

| Quote: | | I purified Ce(III) by precipitating cerium (III) sulfate with concentrated solution of sodium bisulfate (of course sodium sulfate works as well

|

Sodium sulfate shouldn't work? If NaOH can convert Ce(SO4)2 to hydroxide then it wouldn't makes sense for Na2SO4 + Ce(Cl)3 to give you cerium sulfate.

I think you need bisulfate or sulfuric acid...

|

|

|

NADPH

Harmless

Posts: 11

Registered: 1-1-2010

Member Is Offline

Mood: No Mood

|

|

bbartlog

Why sodium sulfate shouldn't work? Cerium (III) sulfate is much less soluble than cerium (III) chloride. I think there shouldn't be huge difference if

I use sulfate or bisulfate or sulfuric acid

|

|

|

bbartlog

International Hazard

Posts: 1139

Registered: 27-8-2009

Location: Unmoored in time

Member Is Offline

Mood: No Mood

|

|

Sodium sulfate shouldn't undergo metathesis reaction with cerium chloride. In the case of the bisulfate or sulfuric acid the cerium is displacing the

hydrogen, but it doesn't seem that it should be able to displace sodium.

|

|

|

NADPH

Harmless

Posts: 11

Registered: 1-1-2010

Member Is Offline

Mood: No Mood

|

|

a) NaHSO4 => Na(+) + HSO4(-) <=> Na(+) + H(+) + SO4(2-)

b) Na2SO4 => 2Na(+) + SO4(2-)

___________________

c) Ce(3+)(aq) + SO4(2-)(aq) => Ce2(SO4)3 (s)

I still don't think there will be any difference if I use different sources of SO4(2-) ions

so I will make some Na2SO4 and try to precipitate Ce2(SO4)3.

I am almost sure it will work

_________________

p.s.

sulfate works

I just dissolved some Ce(OH)4 in nitric acid

then reduced Ce (IV) to Ce (III)

and added sodium sulfate solution. White Ce (III) sulfate was formed.

________________________

p.p.s.

I just did slightly different experiment.

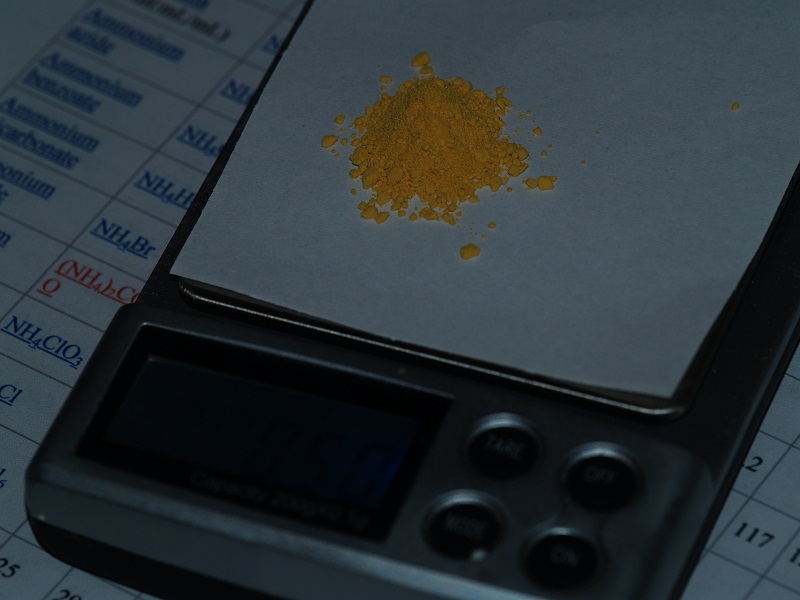

weighted stochiometric amounts of Ce(OH)4 (2 g) and NH4NO3 (1.34 g)

dissolved Ce(OH)4 in ~14M nitric acid. Reaction was exotermic with lot of heat an fizzing. Eventually clear orange liquid formed.

Meanwhile I dissolved NH4NO3 in hot water. Then added it to cerium solution.

then poured on small petri dish

and gently evaporated in oven @120C until solid crust of CAN was formed

when I tried to stir with glass rod, the crust absorbed all remaining liquid and turned in dry hydrate. (According to literature its chemical formula

is (NH4)2Ce(NO3)6*xH2O; x=6-8)

As a result I got 4.4 g of CAN hydrate

[Edited on 14-2-2010 by NADPH]

|

|

|

The WiZard is In

International Hazard

Posts: 1617

Registered: 3-4-2010

Member Is Offline

Mood: No Mood

|

|

Pradyot Patnaik

Handbook of Inorganic Chemicals **

McGraw-Hill

2002

Sez ..... electrolytic oxidation of cerous nitrate in nitric acid

to ceric nitrate, followed by the addition of ammonium

nitrate solution.... Or... dissolving cerium (II) oxide ,

CeO-H2O in con. nitric acid followed by treatment with

ammonium nitrate.

** The book was reminded and could have been had

inexpensively a few years ago.

|

|

|

Copenhagen

Harmless

Posts: 13

Registered: 18-6-2010

Member Is Offline

Mood: Lattice vacancies

|

|

I performed an experiment where I tried to obtain Cerium( IV) Sulfate from crude Cerium(IV) Oxide.

Bottger, W. Newer Methods of Volumetric Analysis pg. 27-28

Trial 1

50 g of CeO2 (FW: 172.115 g/mol) were placed into a 600-mL beaker containing 50 mL of 36 N H2SO4 that was pre-heated to 120 C with magnetic stirring.

Addition was slow - scoopfuls at a time using a plastic spatula. Slow addition seemed prudent due to violent bubbling of the sulfuric acid upon

addition of the solid. The careful addition of CeO2 was completed after 1 hour. The solution was heated for an additional 2 hours at 120 C. It was

allowed to cool at room temperature for 30 minutes after which time it was slowly added to a 3000-mL beaker containing 1800-mL of cold water

temperature (3 C). The solution was allowed to settle for 2 days after which time the supernatant was drawn off in portions with a 50-mL Pipet and

transferred into a 250-mL Erlenmeyer flask. The rest of the solution was stored away in the 3000-mL beaker to allow for further settling.

Trial 2

200 g of CeO2 (FW: 172.115 g/mol) were placed into a 600-mL beaker containing 200-mL of 36 N H2SO4 that was pre-heated to 120 C with magnetic

stirring. Addition was slow - scoopfuls at a time using a plastic spatula. Slow addition seemed prudent due to violent bubbling of the sulfuric acid

upon addition of the solid. The careful addition of CeO2 was completed after 82 minutes. The reaction was heated for an additional 2 hours at 120.

After 2 hours it was removed from the heat source and allowed to cool at room temperature for 4 hours. The supernatant was drawn off in portions with

a 50-mL pipet and stored in a separate container. The precipitate was allowed to dry in room air. The precipitate has the bright yellow color

typical of Ce(SO4)2.

Attachment: VolumetricAnalysis.tif (64kB)

This file has been downloaded 1645 times

|

|

|

The WiZard is In

International Hazard

Posts: 1617

Registered: 3-4-2010

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by garage chemist  | The Ce(IV) ion is a powerful oxidiser in aqueous solution, stronger than chlorine, and capable of very interesting reactions, especially in organic

chemistry.

When its oxidising properties are to be used in preparations, it is most commonly employed as the salt ceric ammonium nitrate, or short CAN:

(NH4)2Ce(NO3)6

I think that this reagent has received. |

Uses? Not in my life. I received 5-6 lbs as a gift years ago...

The only use I am aware of is the analysis of the nitrogen content

of azides. And for the destruction/disposal of azides.

Run it through Google.com/books

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Lots of uses for CAN A test for alcohols, which form a red complex then oxidise away. In inorganic and organic quantitative analysis, as an

oxidising titration reagent; less common now due to various instrumental analysis methods. It can cleave the carbon bond in glycols HO-C-C-OH

similarly to lead tetraacetate. A good way to oxidise many aromatic compounds to quinones.

Its oxidation of alcohols, aromatic amines, and phenols, make it useful in TLC for visualising those compounds.

Attachment: ceric_ammonium_nitrate_in_modern_chemical_synthesis.pdf (748kB)

This file has been downloaded 1553 times

|

|

|

DJF90

International Hazard

Posts: 2266

Registered: 15-12-2007

Location: At the bench

Member Is Offline

Mood: No Mood

|

|

Its also used for selective mono-debenzylation of tertiary amines, and for a few oxidations aside what not_important mentions; formation of quinones

rings a bell...

|

|

|

| Pages:

1

2 |