| Pages:

1

2

3 |

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

Magic, If HazMat is such a problem, try to find a supplier that is near you, so you can pick up a large amount at once.

Maybe the supplier I gave you for potassium iodide could send it to you, with no HazMat. Did you buy your KI there?

|

|

|

MagicJigPipe

International Hazard

Posts: 1554

Registered: 19-9-2007

Location: USA

Member Is Offline

Mood: Suspicious

|

|

len1, maybe you know. What do they mean by "Distilled White Vinegar". Surely if they distill the vinegar there can't be any sugars. There's a

thread called "Sodium Acetate Discoloration" where someone mentions what the impurities might be.

"There must be no barriers to freedom of inquiry ... There is no place for dogma in science. The scientist is free, and must be free to ask any

question, to doubt any assertion, to seek for any evidence, to correct any errors. ... We know that the only way to avoid error is to detect it and

that the only way to detect it is to be free to inquire. And we know that as long as men are free to ask what they must, free to say what they think,

free to think what they will, freedom can never be lost, and science can never regress." -J. Robert Oppenheimer

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

I have not seen distilled white vinegar here. My experiments were with white vinegar of course (since the brown variety is obviously high in

impurities. It does sound like its worth investigating.

It is of course possible to distill white vinegar yourself - that should eliminate sugars to a degree - but imagine distilling 2L, then reacting with

baking soda (which also contains sugars) then boiling it down, then reacting with H2SO4 all for just 20gram or so of GAA. I still think acetone, or

oxidation of meths is a better way.

|

|

|

microcosmicus

Hazard to Others

Posts: 287

Registered: 31-12-2007

Member Is Offline

Mood: spin up

|

|

| Quote: |

baking soda (which also contains sugars)

|

Huh? Every time I have encountered baking soda, it has

been NaHCO3. Maybe it contained some impurities like

K or Mg or Ca instead of Na, but most definitely no

organic stuff.

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

I have been calcining NaHCO3 recently to turn it to Na2CO3, and found solutions of the latter to always have a light brown colour. I presume from

organics decomposed during calcining.

|

|

|

MagicJigPipe

International Hazard

Posts: 1554

Registered: 19-9-2007

Location: USA

Member Is Offline

Mood: Suspicious

|

|

What kind of baking soda do you use len1? I buy USP baking soda from the grocery store and I have never had brown solutions from it. It's always a

very pure white color even when I heat it to Na2CO3 and dissolve the solutions are very clear.

Also, distilled white vinegar should be in your local grocery store in the condiments section. Even the generic (Kroger) brand is distilled where I

live.

The only problem is that NaAc derived from this distilled vinegar turns brown upon heating and it's solutions are brown as well. That doesn't really

matter if you're making GAA though. It only takes a few hours to boil down the vinegar and I get huge pan fulls of NaAc every time.

Still, buying GAA is easier and if the price is low enough it should be done that way. It just so happens though, for me, doing it this way is MUCH

cheaper because of HAZMAT fees and it's unavailability in my area.

"There must be no barriers to freedom of inquiry ... There is no place for dogma in science. The scientist is free, and must be free to ask any

question, to doubt any assertion, to seek for any evidence, to correct any errors. ... We know that the only way to avoid error is to detect it and

that the only way to detect it is to be free to inquire. And we know that as long as men are free to ask what they must, free to say what they think,

free to think what they will, freedom can never be lost, and science can never regress." -J. Robert Oppenheimer

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

"Distilled" refers to the alcohol (later denatured with ethyl acetate perhaps) used to make it, not the product. If it was, it wouldn't be vinegar

anymore, it would just be dilute acetic acid.

Recrystallization and decolorization of boiled down some neutralized vinegar will eventually give a decent white product. Charring on adding sulfuric

acid is a problem with CP acetate even, it must be added slowly and with good stirring which is very unpleasant if not done in a flask or in a hood.

I've never tried bisulfate with acetate, but if someone should try, that would be an interesting report for posting here. I've made formic acid (and

CO!) in this way in the past, I've since forgotten the patent number that I read this in.

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

Ive used two brands on NaHCO3 and they both produced various amount of charred organics when calcined. This was one of the reasons why a final steam

distillation step was necessary in my benzaldehyde purification. I also have lab grade carbonate, but it costs about $40/500gms and I dont want to

waste it on just purification.

The brands (MacKenzies is one) wont mean much to you as theyre Australian - but it does mean that the US chemical industry has outstripped ours, which

prob still uses 19th century methods, like Leblanc. Do what I can theres no distilled vinegar at my local store - you guys in the US just have life

too good

Still lets do the economics - vinegar cells for about $1.50/L, so for a 10L run (which would have to involve bucket chemistry rather than lab

apparatus) youd get about 200gms GAA (including losses) - for $15 - thats $75/L not counting the acid and all the hassles with distillation (thanks to

SC Wack for clarifying that - I had always thought white vinegar was meant as dilute AA) calcination, and redistillation fro H2SO4. Alcohol costs

$2.50/L, acetone $10/L so the economics are clear

[Edited on 29-3-2008 by len1]

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

I just tried heatingbaking soda purchased at a local shop, no sign of charring when slowly heated to 500 C, although it did get agitated as it

decomposes to the carbonate.

In the USA most sodium carbonate and bicarbonate come from the mining of nahcolite and trona, some other regions have deposits of one or the other.

If there are no useful deposits of those, the Solvay or Hou processes. China uses Hou, Solvay, and mined trona in decreasing magnitude, Australia

seems to be using Solvay although they may be switching over to Ou to eliminate the CaCl2 byproduct which has little demand there.

Solvay and Hou shouldn't be leaving organics in the bicarbonate, which normally is one of the purest chemicals produced on a large scale. Perhaps

other members could perform the test, and see if we can localise this as well as determine the nature of the charring.

Your vinegar is expensive, that is at least thrice what I pay. And with no need to calcine the economics would be different in my case.

Isopropyl alcohol can be used to extract much of the coloured matter from the crude sodium acetate hydrate. An alternative is the dehydration of the

hydrate by slowly added the powdered solid to refluxing alcohol-toluene and allowing the water azeotrope to distill off. Finish up by distilling the

alcohol-toluene azeotrope and you have powdered anhydrous sodium acetate with the organics in toluene solution.

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

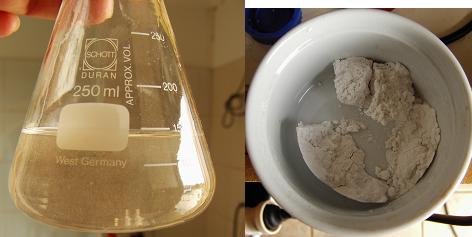

Ill post a few pics shortly just so that you can see what we Australians have to make do with

[Edited on 29-3-2008 by len1]

|

|

|

MagicJigPipe

International Hazard

Posts: 1554

Registered: 19-9-2007

Location: USA

Member Is Offline

Mood: Suspicious

|

|

Yes, vinegar here (distilled white, thanks for the info on that S.C. Wack, I always had a feeling they were referring to the alcohol used to make it

and not the vinegar itself, otherwise there shouldn't be any brown products!) comes in gallon containers for about $1.50.

So, at that price and the price of H2SO4 it comes out to being a little bit cheaper than ordering GAA online for me. If I factored the isopropanol in

it would be about the same because I can get anhydrous IPA for a few dollars a gallon, as well.

Now, if only my time and hard work was worth the remainder!

PS. Speaking of bulk alcohols, I also found a source of absolute EtOH for an EXCELLENT price. And the acetone is even cheaper so now the

acetone/EtOH method seems like a good option now. Is there a thread covering it? I really did hit the jackpot with this solvent supplier!

[Edited on 29-3-2008 by MagicJigPipe]

"There must be no barriers to freedom of inquiry ... There is no place for dogma in science. The scientist is free, and must be free to ask any

question, to doubt any assertion, to seek for any evidence, to correct any errors. ... We know that the only way to avoid error is to detect it and

that the only way to detect it is to be free to inquire. And we know that as long as men are free to ask what they must, free to say what they think,

free to think what they will, freedom can never be lost, and science can never regress." -J. Robert Oppenheimer

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Note that the IPA can be mostly recovered with simple distillation, so it's a lesser expense. Some sodium acetate is extracted by it, on a large

scale that might be work recovering.

Calcium carbonate or hydroxide can be used in place of sodium carbonate or bicarbonate; this has the advantages that they are very cheap, and that

calcium acetate seems to be bit less soluble in alcohol that the sodium salt. If you're using sulfuric acid to displace the acetate then the removal

of some of the water by the CaSO4 can reduce the dehydration requirements - the monohydrate is quite acceptable.

By acetone I assume you mean via haloform reaction, which may be hiding in chloroform threads. Ethanol to acetate means more direct oxidation, the

OCl(-) with nickel catalyst would seem to be a reasonable route there. Note that denatured ethanol is likely to contain methanol, giving formic acid

mixed with the acetic.

|

|

|

Formatik

National Hazard

Posts: 927

Registered: 25-3-2008

Member Is Offline

Mood: equilibrium

|

|

| Quote: | Originally posted by evil_lurker

I'm working on a way to get as close to pure acetic acid without having to order it and pay those outrageous hazmat fees.

I know that you can reduce vinegar down to sodium acetate, and mix it with 98% sulfuric acid and get a finished product close to glacial.

|

Either that or you could heat and distill dry wood (sawdust). And then if you react the distillate with calcium hydroxide, calcium acetate results:

Ca(OH)2 + 2 CH3COOH -> (CH3COO)2Ca + 2 H2O. Then get the acid by reaction with sulfuric acid, that can be separated by distillation: (CH3COO)2Ca +

H2SO4 -> CaSO4 + 2 CH3COOH. Details in Thorpe, Vol.1, p. 11-24. Just a theoretical.

|

|

|

Baphomet

Hazard to Others

Posts: 211

Registered: 19-11-2006

Member Is Offline

Mood: No Mood

|

|

I've tried reacting H2SO4 and Na.Acetate, then distilling it.

The operation was fairly successful but being unable to stir the mixture meant a lot of heat needed to be applied. This resulted in a yellowing of the

acetic acid produced, and a smell of SO2 (around 5ppm?)

So perhaps Na2SO4 decomposed during the distillation? My question is: what is the best protocol for doing this?

Also I've noticed that Na.Acetate must go through 3 cycles of roasting and crushing to reach the anhydrous state.. also it should be kept in a sealed

container while cooling between cycles. Best results were obtained by grilling first, then using a microwave oven.

\"Who ARE you? You\'re like the drummer from REO Speedwagon - nobody knows who you are\" from \'Employee of the Month\'

|

|

|

Sedit

International Hazard

Posts: 1939

Registered: 23-11-2008

Member Is Offline

Mood: Manic Expressive

|

|

If the sodium acetate was obtained from vinegar then it should be recrystalized to rid it of other organics and possibly traped volatiles. I cant

stress this enough because it is the difference between good acid and one that is yellow and will eventually form a scum layer atop of it. You are

correct with the time it takes to get the sodium acetate dry. It is a royal pain in the ass but well worth it in the end.

A test with the addition of 35% H2O2 will show you how much other unwanted stuff is in there by forming a clear peracetic acid from the yellow

solution and bringing the contamination to the surface where it can be seen clearly as a layer of scum.

After reading thru this threed has anyone as of yet really made it using Bisulfite? I'v used sulfuric many times with good results but I have some

Sodium pyrosulfite that I could possibly use to test if no one else has attempted it yet. Im a little concerned with SO2 contamination and release

using this though.

Knowledge is useless to useless people...

"I see a lot of patterns in our behavior as a nation that parallel a lot of other historical processes. The fall of Rome, the fall of Germany — the

fall of the ruling country, the people who think they can do whatever they want without anybody else's consent. I've seen this story

before."~Maynard James Keenan

|

|

|

crazyboy

Hazard to Others

Posts: 436

Registered: 31-1-2008

Member Is Offline

Mood: Marginally insane

|

|

http://www.apcforum.net/forums/blog/crazyboy25/index.php?sho...

This is how I did it.

|

|

|

no1uno

Harmless

Posts: 30

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Here is "AN" answer, maybe....

| Quote: | In the system ethyl acetate/acetic acid/water, a binary azeotrope exists between water and ethyl acetate (Boiling point 70.4 Deg. C). The separation

by distillation of water and acetic acid in the ethyl acetate can be done without too many problems. As far as running costs are concerned. one must

take card that the ration of ethyl acetate/water used in the column corresponds to the maximum volatility for acetic acid. Consequently the feeds to

the extraction column must be held within closely controlled limits, necessitating a carefully designed control system.

http://www.ddpsinc.com/ProcessProfiles/pp50.html |

Separating the ethyl acetate & acetic acid looks likes fun

|

|

|

no1uno

Harmless

Posts: 30

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Sorry for the double-post (been busy trying to build a website)...

I had that wrong, use the ethyl acetate to extract the acetic acid from white vinegar, then distill off the ethyl acetate/water azeotrope @ 70.4C...

What you are left with will be a strong acetic acid solution.

Point 1

I've seen somewhere the suggestion that fractional freezing (?) can be used to purify strong acetic acid solutions, I've no idea as to the validity of

these claims.

Point 2

It might be possible to remove the remaining water by azeotropic distillation, using ethanol, or acetone or something similar.

Point 3

In order to dry ethyl acetate, I've seen it suggested elsewhere to use hexane/toluene and NaCl to make a 2-phase solution. Personally I've tried the

use of CaCl2 to separate EtOAc/EtOH/H2O, which does form a 2 phase solution, however given the bp of the resultant EtOAc I'd say it was less than

completely effective.

PS Anyone got ANY ideas? This is just guesswork till I get my glass again, anyone else want to try it?

|

|

|

starman

Hazard to Others

Posts: 318

Registered: 5-7-2008

Location: Western Australia

Member Is Offline

Mood: No Mood

|

|

I don't know about the fractional freezing of stronger solutions,but there are a number of claims of using freezing to concentrate dilute

solutions(vinegar) to a concentration of circa 30%.(saw a webpage complete with pictures sometime ago).

This would greatly reduce the ethyl acetate required for extraction and thus increase economy/facility of the process.

Chemistry- The journey from the end of physics to the beginning of life.(starman)

|

|

|

16MillionEyes

Hazard to Others

Posts: 153

Registered: 11-3-2007

Location: 16 Million Eyes, US

Member Is Offline

Mood: No Mood

|

|

Crystallizing NaCH<sub>3</sub>COO from the vinegar/NaHCO<sub>3</sub> boiled salt can be a serious hassle: it takes days for it

to reach a saturated solution of NaCH<sub>3</sub>COO before it even starts crystallizing; separation is somewhat tedious and, unless done

very carefully, does not lead to an acceptable salt; and lastly, the yields are poor.

I think the best way, for anyone with a distilling apparatus, is to distill their white vinegar before attempting anything. Since most people here

already suggest fractional distillations and so on for the production of glacial, I don't think this will be much of a hassle. Once you've gotten your

relatively pure acetic acid, then work your way to glacial.

In actual terms of the glacial (wasn't there another thread on this, like 6+ pages?), the freezing method works well, only problem is separation. What

I mean is that you can definitely note a rise in concentration, but then, as you separate, ice starts to melt and you inevitably end up with a

solution of acetic acid. Not a bad thing, but seems like it requires a bit of ingenuity to get it to glacial by this method.

[Edited on 15-4-2009 by __________]

[Edited on 15-4-2009 by __________]

|

|

|

franklyn

International Hazard

Posts: 3026

Registered: 30-5-2006

Location: Da Big Apple

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by starman  | I don't know about the fractional freezing of stronger solutions,but there are a number of claims of using freezing to concentrate dilute

solutions(vinegar) to a concentration of circa 30%.(saw a webpage complete with pictures sometime ago).

This would greatly reduce the ethyl acetate required for extraction and thus increase economy/facility of the process. |

Step 1

http://www.alchemywebsite.com/distillation_of_vinegar.html

Step 2

U.S. Patent 2422504

http://www.sciencemadness.org/talk/viewthread.php?tid=10545#...

Source _

www.soapgoods.com/Activated-Carbon-Carbon-Hydrodarco--p-1007...

.

|

|

|

Sedit

International Hazard

Posts: 1939

Registered: 23-11-2008

Member Is Offline

Mood: Manic Expressive

|

|

Sorry to intrude here on the discussion at hand but I seen this thread revived and wanted to ask a question for everyone here.

What would be the best way to produce AcOH from EtOH in an electrochemical cell? I'v tryed a variety of methods which I couldn't recall off the top of

my head without gathering and reviewing my hardcopy notes(most got lost in a computer crash) and what was noted in almost every attempt was a strong

smell of Acetaldahyde. This obviously equates to a large lose of product. I also tried oxidation of EtOH with Nitric acid which I honestly feel has

much potential but that also yeilds alot of AcO product as well.

I think in terms of economics electrochemical oxidation could be the way to go followed with a salting out of the formed AcOH and DCM extraction.

Given that DCM evaporates quickly, cleanly and more importantly its easy to recover even with a makeshift "Bucket" form of distilling apperatus it

would allow someone to make large amounts cheep with reusable reagents instead of wasting H2SO4 or a host of other reaents in trying to prepare AcOH.

I think it could even beat out Lens Haloform economics if enough for thought was put into its workings.

So any ideas on what to use in a cell to get the oxidation done quickly and easy? What about the AcO formation how to quell its formation enough to

give good yeilds? An acidic cell would be best else your back to using H2SO4 to release the AcOH for distillation.

Knowledge is useless to useless people...

"I see a lot of patterns in our behavior as a nation that parallel a lot of other historical processes. The fall of Rome, the fall of Germany — the

fall of the ruling country, the people who think they can do whatever they want without anybody else's consent. I've seen this story

before."~Maynard James Keenan

|

|

|

Picric-A

National Hazard

Posts: 796

Registered: 1-5-2008

Location: England

Member Is Offline

Mood: Fuming

|

|

I guess acetaldehyde is the intermediate oxidation compound, ie:

ethanol--> acetaldehyde --> acetic acid

Thus you want to leave the acetaldehyde in until complete oxidation, dont try remove it.

|

|

|

bbartlog

International Hazard

Posts: 1139

Registered: 27-8-2009

Location: Unmoored in time

Member Is Offline

Mood: No Mood

|

|

| Quote: | | Since most people here already suggest fractional distillations and so on for the production of glacial |

Care to point to even one member here who has done fractional distillation of acetic acid and recommends it as a way to produce glacial acid? Because

as far as I can tell this is extraordinarily arduous, and no one who has done it seems to think it's the right way to go. I tried this (starting with

~40% acetic acid and using a Hempel column to concentrate the acid) and the separation is simply not efficient enough. Starting with anhydrous

reagents and/or using sulfuric acid to trap water in the system seem to be the universally preferred approach.

|

|

|

The WiZard is In

International Hazard

Posts: 1617

Registered: 3-4-2010

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by evil_lurker  | I'm working on a way to get as close to pure acetic acid without having to order it and pay those outrageous hazmat fees. [snip]

|

British medical journal

February 23, 1867

Of the chemical preparations in the new edition of the Pharmacopoeia, the acids have probably undergone the most important alterations. The very

impracticable process for Glacial Acetic Acid given in the last edition is now omitted ; and we have simply a description of the characters by which

the substance is to be recognised. In point of fact, no good process exists by which the acid can be prepared at all economically on a small scale;

and, indeed, very little of the acid is made in this country. It is imported chiefly from Germany; and, under these circumstances, a good description

was all that was required for pharmacopoeial purposes.

Noted in passing :—

Probable more that you want to know.

William Theodore Brannt

A practical treatise on the manufacture of vinegar: with special ...

1900 543 pages

Google.com/books

|

|

|

| Pages:

1

2

3 |