| Pages:

1

2

3

4

5

..

18 |

vulture

Forum Gatekeeper

Posts: 3330

Registered: 25-5-2002

Location: France

Member Is Offline

Mood: No Mood

|

|

I would suspect the NaOH would dissolve the TiO2 layer and form sodiumtitanate, but I may be wrong...

One shouldn't accept or resort to the mutilation of science to appease the mentally impaired.

|

|

|

BromicAcid

International Hazard

Posts: 3253

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

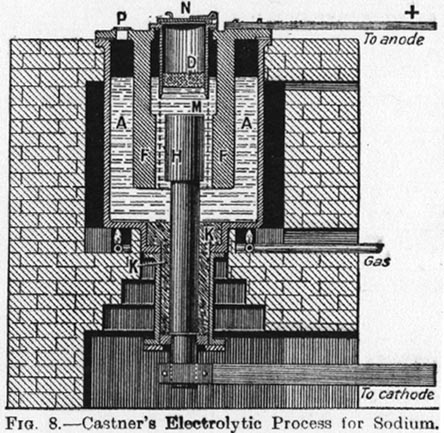

Like I said, a picture of another, Castner Tiegel. This one with additional explantions.

| Quote: |

The sodium hydroxide, contained in an iron pot set in brickwork, is melted by means of a ring of gas jets placed underneath; and kept about 20 C above

the m.p. (318C) of sodium hydroxide. The cathode, H, of nickel or iron rises through the bottom of the iron pot, A,

Fig. 8, and is maintained in position by a cake, K, of solid sodium hydroxide in the lower part of the pot. THe anodes,

F, several in number, are suspended around the cathodes from above. A cylindrical vessel, ND, floats in the fused

alkali above the cathode, and the sodium and hydrogen liberated at the cathode collect under this cylinder. The hydrogen escapes through the cover

and the atm. of hydrogen in the cylinder protects the sodium from oxidation. A cage of nickel-wire gauze, M, seperates the anode,

F, from the cathode, H. From time to time the sodium D, is skimmed off by means of a perforated

ladle, which retains the liquid metal, but allows the molten hydroxide to flow back. The oxygen liberated at the anode escape via the vent

P.

|

Simply a beautiful process. One day it will be mine. As for vulture's comment on the use of titnium I didn't even think of that, I was

more worried about hydrogen embrittlement, titanium is strikingly succeptable to that.

Also, I found "Sodium chloride mixed with powdered lead heated red hot in a closed retort gives metallic sodium:

2NaCl + Pb -----> PbCl2 + 2Na

I guess I would list that just for completeness seeing as how our current research into aluminum is paying off so well.

Also, while I'm on a roll, "Upon heating a molten mixture of sodium carbonate and sodium cyanide at a temperature of 1000C, metallic sodium,

carbon monoxide, and nitrogen are formed."

2NaCN + Na2CO3 ----> 4Na + 3CO + N2

[R. Franchot, Ind. Eng. Chem., 16, 235 (1924)]

I also found references to sodium carbonate being reduced by both magnesium and aluminum turnings to yeild sodium metal, which I believe has been

hinted at if not outright stated already.

|

|

|

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

Bromic,

I'm not convinced the aluminium method is worth following up, for reasons Ive explained.

vulture,

I concurr with the worry about titanium in molten hydroxide.

Organikum,

Then there is a problem, becuase if the bell isnt electrically connected to the copper nail at the start of the reaction, it soon will be. A cell

where both electrodes enter from the top seems to require a molten hydroxide stable insulator just like the other designs, and I havnt been able to

find one I can use. The one good suggestion that was made to me was sintered magnesia containing 1% or so waterglass, which only reacts with the

hydroxide very slowly, but I lack a suitable furnace to make it in.

Any idea what insulators the Castner Tiegel cell used?

It would also be nice to know how big the holes in the ladle need to be for surface tention to retain the sodium, but allow the hydroxide to pass

through.

If the battery is just for smoothing the current, then it is not useful in this application. If the cell has 12v over it then too much power is being

wasted for the current that is flowing and it needs redesigning.

|

|

|

Hermes_Trismegistus

National Hazard

Posts: 602

Registered: 27-11-2003

Location: Greece, Ancient

Member Is Offline

Mood: conformation:ga

|

|

Look on the first diagram on the first page, The Holzring is the anode insulator, its made of wood.

Arguing on the internet is like running in the special olympics; even if you win: you\'re still retarded.

|

|

|

Organikum

resurrected

Posts: 2339

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

Marvin

| Quote: |

Then there is a problem, becuase if the bell isnt electrically connected to the copper nail at the start of the reaction, it soon will be. A cell

where both electrodes enter from the top seems to require a molten hydroxide stable insulator just like the other designs, and I havnt been able to

find one I can use. The one good suggestion that was made to me was sintered magnesia containing 1% or so waterglass, which only reacts with the

hydroxide very slowly, but I lack a suitable furnace to make it in.

|

No really not. Hole in bell with filed down nail through it fixed by ovencement as no molten Na should reach the holes for hydrogen escape would be

blocked and boom it makes.

| Quote: |

It would also be nice to know how big the holes in the ladle need to be for surface tention to retain the sodium, but allow the hydroxide to pass

through.

|

Eh? surface tension? I guess this is an misunderstanding. Hydroxide passing through what? Why?

Refill: Take plier. Open lid. Throw in NaOH. Close lid. Do fast.

for the rest:

no. no. no. no.

current efficiency in a quick and dirty tomatosoupcansetup?

no. no. no.

No. sorry.

|

|

|

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

Hermes, there seems to be something inbetween the solidified melt and the holtzring. Its just labled isolation in what I can see, but it must be

molten sodium hydroxide stable and an insulator.

Wood is attacked by molten sodium hydroxide and starts to decompose over about 270C anyway. I dont think we can use this.

Organikum,

From the description it seems the molten sodium will short circuit the nail and the bell long before the bell has filled with sodium. I dont

understand how this is prevented.

One of the features of the castner process is that the sodium is removed by a perforated ladle that retains sodium while draining hydroxide. It would

be nice to know what hole sizes are needed for this.

Adding a battery is only useful over a narrow range of cell voltages. If the cell is not designed to work over this range, the battery will not help.

If it is designed to work over this range then its been designed specifically to work at a voltage that wastes power. Its a lose-lose situation.

Bromic acid,

Very nice going. If you are willing to swap magnesium for sodium potassium etc, and I would be if I could get magnesium cheaply, then you might

prefer the organic solvent method in the patent. Decent yeilds and its easier to get the metal as a single ingot relativly free of magnesium

oxide/hydroxide.

Aluminium and sodium hydroxide is supposed to go mainly to Na3AlO3, a mixture that was formerly used to defrost oil wells and which produces no sodium

directly, formation of sodium is a side reaction with the coproduction of sodium metaaluminate. Magnesium seems the only feasable metalic reducing

agent which limits most peoples ability to use this.

Kaboom, now that would be hydrobromic acid wouldnt it

[Edited on 15-12-2003 by Marvin]

|

|

|

Organikum

resurrected

Posts: 2339

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

molten sodium

seems to be a bad conductor for electricity, Marvin.

|

|

|

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

Molten sodium is one of the best liquid conductors.

Solid copper around e-8, liquid sodium around e-7 liquid mercury about e-6 (perohmpermeter). Its undoutably much better than the molten salt its

displacing/floating on.

Theoretic, based on what?

|

|

|

Organikum

resurrected

Posts: 2339

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

outch.

but it works nevertheless, also I never thought on this ??

|

|

|

hodges

National Hazard

Posts: 525

Registered: 17-12-2003

Location: Midwest

Member Is Offline

|

|

Calcium

I know this thread is about making sodium, but calcium is a similar metal. I found out that CaCl2 actually has a slightly lower melting point than Ca

does. Calcium also does not burn nearly as readily as sodium does (in fact, I had a hard time getting a small hunk of Ca to burn even with a

blowtorch). Yet it still reacts fairly well with water. And CaCl2 is cheap and plentiful (dehumidifier powder or ice melter).

I would think Ca would be significantly easier to make than Na. Might be a good first try for someone who has never made Na.

I tried making sodium from lye when I was 14. I heated up some in a large spoon, using the spoon for the anode and a wire for the cathode. As I

recall, I got vigerous bubbling (much more so than when electrolysing water, for example). The hydrogen kept exploding and blowing out the alcohol

lamp I was using to heat it. I had a small gray lump near the cathode that I tried putting some into water with a tweezers. Nothing appeared to

happen. But when I touched the lump again with the wet tweezers there was an orange spark. Have never tried making it again since then.

Hodges

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

Yes, calcium would be easier to make than sodium.

I remember reading a description of the setup to make calcium in the lab. It involved the use of a screw-like iron electrode which would be lifted

from the molten CaCl2 as calcium was being deposited, leaving only a tip of calcium in.

I'm traveling now and can't read my books to find out why can't you just leave the deposited calcium in the molten salt. This would

even prevent oxidation.

When I return home, I will find out and post. Maybe we should start a "Calcium!"

thread.

Although you can use calcium to dry solvents and make some interesting reactions, sodium BURNS, or even EXPLODES with water! UNDER water! You

can't beat that! A "Calcium!" thread sure would not be as popular as this one.

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

A bit off topic but how much shouldc a graphite electrode cost?, I saw one today for 12$ CDN. It is about 6mm wide by 15 cm long

|

|

|

Saerynide

National Hazard

Posts: 954

Registered: 17-11-2003

Location: The Void

Member Is Offline

Mood: Ionic

|

|

Wow, thats really expensive. I got a pack of 6 of carbon rods about 1 cm x 15 cm for less than $2.

Edit:

I dont live in the US, so you wouldnt know were I got them from anyways

But if you insist, I got them at a local shop that sells plants stuff.

[Edited on 8-1-2004 by Saerynide]

|

|

|

BromicAcid

International Hazard

Posts: 3253

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

Get it while it's hot!

http://members.aol.com/bromicacid/sodium/index.htm

I don't know how long I'll leave this up, maybe someone can convert to .pdf and host it but for now here it is, go to the page and gander at

the scans I made from "Sodium: Its manufacure, properties, and uses" It is the best reference Ive come across yet regarding both chemical

and an overview of the electrochemical methods to this wonderous element. I have the whole chapter on the production of sodium metal scanned in.

Like I said, get it fast, download it, whatever!

[Plus when I take it down I have to delete this post so that my last post is not a lie.....]

[Edited on 1/13/2004 by BromicAcid]

|

|

|

Polverone

Now celebrating 21 years of madness

Posts: 3186

Registered: 19-5-2002

Location: The Sunny Pacific Northwest

Member Is Offline

Mood: Waiting for spring

|

|

Ahhh, I remember reading that book some months ago. BromicAcid, do you have higher-resolution scans on your computer, that OCR would work on? Whether

you do or not, I'll gladly host a PDF made from the scans (someone else will need to assemble the PDF as I don't have access to Acrobat at

the moment).

|

|

|

Theoretic

National Hazard

Posts: 776

Registered: 17-6-2003

Location: London, the Land of Sun, Summer and Snow

Member Is Offline

Mood: eating the souls of dust mites

|

|

On the topic of separation of sodium from carbon that fell off the electrode... ...sodium forms sodium carbide with carbon, separation must be quick.

An easily meltable salt could be used to do that, it would sink to the bottom, and carbon would sink to the bottom of it, while sodium would float on

top. Also sodium carbide would dissolve in the molten salt.

|

|

|

Polverone

Now celebrating 21 years of madness

Posts: 3186

Registered: 19-5-2002

Location: The Sunny Pacific Northwest

Member Is Offline

Mood: Waiting for spring

|

|

sodium production chapter converted

BromicAcid: the images you had on your website have been turned into a PDF and are now in the <A

HREF="http://www.sciencemadness.org/library/">library</A>. If there are other materials that you want to scan and put online in the

future, I suggest scanning in black and white at 300 or 600 DPI (or scanning in grayscale and then converting to black and white) since it's

cleaner, compresses down to a smaller size, and looks better on screen/in print. But thank you for making that chapter available the way you did.

PGP Key and corresponding e-mail address

|

|

|

KABOOOM(pyrojustforfun)

Hazard to Others

Posts: 254

Registered: 12-10-2002

Location: Iran (pseudoislamic dictatorship of)

Member Is Offline

Mood: exuviating!

|

|

Polverone:<blockquote>quote:<hr>BromicAcid: the images you had on your website have been turned into a PDF and are now in the

library<hr></blockquote>I downloaded it. it gives this error when I open it:

<i>There was an error opening this document. The file is damaged and could not be repaired.</i>

(Thank you in advance)

|

|

|

Polverone

Now celebrating 21 years of madness

Posts: 3186

Registered: 19-5-2002

Location: The Sunny Pacific Northwest

Member Is Offline

Mood: Waiting for spring

|

|

you are quite right

The file I had locally was twice the size of the one in the library. I guess the upload got interrupted before. I have verified that the file now in

the library can be downloaded and viewed.

PGP Key and corresponding e-mail address

|

|

|

Organikum

resurrected

Posts: 2339

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

Castner Tiegel remark

I was irritated all time because of Marvins remark that the molten sodium would give a shortening of the electric current between the "bell"

and the central electrode and make the design unworkable.

But I had done it and it worked.

How could this be?

Solution: The iron bell works is cooled by the air. At the edges inserted in the molten NaOH the NaOH solidifies and forms such an isolator on the

bell. This works because the temperatur of the NaOH is only slightly above the melting temperature of NaOH and the superior heattransfer properties of

iron compared to NaOH.

Try it!

Just put something from iron into just molten NaOH and you will see the solidified NaOH forming a stable protection layer on the iron. And this layer

wont dissolve also not after times.

Nothing shortens here.

Hope this answers your question Marvin?

|

|

|

BromicAcid

International Hazard

Posts: 3253

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

Electrolysis of Sodium Hydroxide

Picture shows my nickel crucible with some sodium hydroxide pellets in it. Anode is just the crucible and the cathode that decends into it is

nickel as well. Below it is the torch that I was using to heat it.

Too awhile for everything to melt. The hydroxide pellets on the top solidified together and formed a crust, I didn't realize it was all

liquid underneath till I poked at it with a nickel rod, it all caved in and melted together. The solution was white till it all dissolved then turned

crystal clear. Electrolysis was begun using a 9V battery.

Very soon after this there were bubbles at both the edge of the crucible and at the cathode. No sodium though, but the solution darkened to a

yellow color.

Thinking that maybe the solution was too hot and that any sodium being produced was reacting back with the hydroxide at this temperature I

turned off the heat. A crust quickly formed over the top that bubled up due to gas formation. Some sodium may have been formed but I could not tell.

After awhile the bubbles stopped so I turned the heat back on.

Not long thereafter I decided that maybe it wasn't a good idea to use the crucible as the anode so I grabbed a piece of nickel rod and put

the clip on that and manually held it in place. Bubbles started to rise immediately but the hydroxide solidified around it and it took awile to take

on enough heat to where it conducted again. You can see a black crud around it, I believe the sodium was going into solution and where ever the

hydroxide was solidifying it was darkening more and more.

The hydroxide solution turned almost black and no longer produced bubbles. The metaloid that has been mentioned. I discontinued electrolysis

and heating. I let it cool a bit and added water, very violent reaction but it was a block of hot hydroxide after all.

During the whole procedure I saw no sodium gobules. But as the solution darkened I was sure there was some around there somewhere. The nickel

crucible came out with no noticeable errosion but it had a black residue on it. What's everyone think, was the NaOH too hot, too much voltage,

not enough, current, electrolysis really isn't my strong point. Also this cell really isn't anything like the one that I've been

working on, this was mostly just a proof of principle thing makes it even worse that it didn't work for me.

[Edited on 4/4/2004 by BromicAcid]

|

|

|

hodges

National Hazard

Posts: 525

Registered: 17-12-2003

Location: Midwest

Member Is Offline

|

|

I think if by "9V battery" you mean one of those tiny things a few centimeters square and about 1 centimeter thick, it did not have enough

capacity to do much electrolysis. A power supply is best. Lacking that, use a 12-V auto or motorcycle battery. Lacking that, use a 6V alkaline

lantern battery.

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

I have also tried NaOH electrolysis a number of times (under conditions as you describe), with the same results as you. A blackish residue was left,

that violently reacted with water.

I used a powersupply, with as much amperage as it could take (the amperage being restricted by the resistance), @ 12 V.

Never any success that way. I believe it can't be done this way, this has to be done in a properly designed vessel, with proper temp. control,

etc.

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

I had several sucesses with small amounts of hydroxide and one failed attempt when I tried to scale it up (before I had a good idea how.

Hodges is right, you arnt getting enough current from the battery. I used a 12v PSU capable of delivering about 7A. The voltage was much higher than

it needed to be, the PSU sounded almost like it was directly shorted when running. 7A though is the very minimum Id consider using as a proof of

concept. A car battery or motorcycle battery might deliver far too much cuttent for too short a time to be useful. Formation of sodium was very slow

at 7A though its halo was impressive, best part of the experiment IMHO.

Ideally you should be pumping almost almost enough power into the cell that it stays molten without external heating - this makes it much easier to

keep it around its melting point. I would also expect an induction period before sodium starts to form as the mixture dehydrates.

Edit,

Also watch out for the small explosions as the sodium sets the hydrogen bubbles off. This tends to send sodium metal flying round the room and

limited the amount I could let form as a globule before I had to remove it, or lose it. Eye protection a must, though I think you know this. Thick

gloves also as the fumes tend to attack skin.

[Edited on 5-4-2004 by Marvin]

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by hodges

I think if by "9V battery" you mean one of those tiny things a few centimeters square and about 1 centimeter thick, it did not have enough

capacity to do much electrolysis. A power supply is best. Lacking that, use a 12-V auto or motorcycle battery. Lacking that, use a 6V alkaline

lantern battery. |

I agree. You need much more current than this batteries can provide. At least a couple of amperes (edit) considering the size of your setup.

When I tried to do an open air electrolysis of NaOH, I could not get any metal due to the fact that sodium burns at this temperature, but I could see

the little orange sparks in the cathode. Can you see those?

You seem well equiped, can't you built the "bell" proposed some time ago in this thread?

[Edited on 5-4-2004 by Tacho]

|

|

|

| Pages:

1

2

3

4

5

..

18 |