Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Preparation of sulfur monochloride S2Cl2

Initially I wanted to post this the thread Garage Chemist started a few years ago, but considering the rather large screen size needed to visualize

the whole thread, i prefered starting a new one.

A note concerning the cleaning of sulfur deposit on glassware: having heard of how annoying sulfur is to remove of glassware, i aprehended the

cleaning. I've found out that a base bath (KOH/NaOH in EtOH/IPA) is terribly efficient at removing it. A single night soak removed a black, burnt

sulfur deposit entirely. All the glassware came out as new, though i thought i was going to have to use pirhana (sp?) on this. Once more, I can only

recommend preparing such a base bath for people willing to stop spending hours removing organic residu off glassware. No more scrapping of the glass

surface from scrubbing with soap. Be sure to use adequate protection though (full facial protection, thick propylene gloves, lab coat and tight lid).

Preparation of Sulfur Monochloride by chlorination of Sulfur

S2Cl2 is said to be produced in high yield by bubbling dry Cl2 in hot, melted sulfur, with direct distillation of the formed S2Cl2.

The sulfur was obtained by purifying 80% gardening sulfur, by hot xylene extraction, a task I wouldn't give to my worst enemy. it smells bad, clogs

up any filter fine enough to prevent the small black particules to pass, and spoils alot of glassware for little product. Next time (if ever), i will

buy sublimed sulfur. I finally isolated over 50g of pur-ish sulfur.

The chlorine was produced by dripping 15% HCl over a TCCA slurry, as per Len's excellent document (original work by Organikum, sorry for typo!).

Indeed, it produced a constant, easily monitered flow of chlorine, which was dried over CaCl2.

I made two attempts, the first one not producing a workable amount of distillate, the second being much more succesfull.

In the first attempt, stoechiometric amount of chlorine was passed, and in the second 1.5 excess was used. Although the success of the second didn't

only depend on the use of excess chlorine, using at least 2x excess would give rise to higher yields, any formed SCl2 being reduced to S2Cl2 upon vac

distn of the crude distillate over sulfur.

First attempt

The setup was composed of:

- A pressure-equalized addition funnel attached to a erlenmeyer, connected to a wash bottle full of granulated CaCl2, itself connected to a gas

admission tube.

- A 100mL RBF, fitted with gas admission tube, a thermometer, magnetic stirring, and a adaptator in the central 29/32 neck.

-A simple distn setup, connected to the top of the adaptator

-A anti-suck back wash bottle, with a bed a CaCl2 (avoid admission of moist air), connected to a inverted full immersed in 30% NaOH solution to

neutralize unreacted chlorine.

Complete setup:

15g (~<0.5 mol) of sulfur where introduced in the RBF, 17g (~>70 mmol) of 92% TCCA powder were introduced in the erlenmeyer and slurried with

a little dH2O, and 48mL of 15% w/v HCL introduced in the addition funnel.

The RBF was heated with a mantle to 150°C. The sulfur started to melted above 110°C. The gas admission tube was then lowered as far as possible

under the melted sulfur.

The HCl was then slowly dripped over the TCCA slurry, causing some bubbling and evolution of green Cl2 gas, until a flow of 1-2 bubbles/sec were

passing through the sulfur.

There was some bubbling at the NaOH trap. After 5 min, some yellow droplets were seen refluxing on the sides of the flask.

Gassing was continued, and heating increased to above 180°C, and, even with strong insulation with aluminium foil, hardly any distillate was seen

passing over, even though there was some reflux on the central neck of the flask. The gassing took a little less than 2 hours, and only a few drops of

red distillate had been collected. During the gassing, there was constantly a little bubbling in the trap, apparently there was quite some unreacted

Cl2. Heating was increased again. When HCl addition was finished and the Cl2 generator produced only a very faint flow of gas, it was disconnected

from the flask, and the Cl2 trap was replaced by an aspirator. Vacuum was applied, but only a few mL of dark red distillate were obtained. The pot

temp increased over 230°C, the take off came to a halt, so heating and vacuum were cut. A total of 4mL of red distillate was obtained.

The major problem was that the S2Cl2 vapors couldn't travel through the 5cm long adaptator, even with the insulation. I guess it finally turned to

crap, as only a high boiling residu was left in the flask. Upon cooling, it turned to a very thick black tar, and i was scared i would never get my

favorite RBF clean. Hopefully, scrapping under boiling xylene, and 24h soak in the base bath got it as new.

Second attempt

This time, a single neck 100mL RBF was used, and the gas inlet tube was fitted in the distn head, at the place of the thermometer. I had no means of

reading the internal temperature though. The same, cleaned Cl2 generator was used, but the distn setup was used directly, without any cleaning. A fine

layer of sulfur had appeared on the inside, from the hydrolysis of the sulfur chlorides by the moist atmosphere overnight. The same Cl2 trap was used

(added some fresh 30% NaOH).

Again, 15g of sulfur was heated until it melted, the gas inlet tube immersed as deep as possible, and gassing started when the sulfur turned a

little more brownish. The same amount of TCCA/HCl as in the first attempt was used. The setting on the mantle was roughly the same as when a

temperature of 200°C was attained in the first attempt. The gassing was done a little more quickly this time. Pretty soon, a yellow liquid was seen

refluxing on the sides of the flask.

Hopefully, a orange/red distillate started passing after 30min of gassing (heating had been slightly increased), some white smoke was seen in the

condenser too. This time, there was hardly any bubbling in the trap. The distillate cleared up to a more golden yellow/orange color.

When all the HCl had been dripped in, the erlenmeyer was shaken for a while to get most of the Cl2 out. It was obvious that the take-off increased

with the gas flow, surely by "pushing" the vapors up to the distn head. A second erlenmeyer was charged with 8g of TCCA, slurried with a little water,

and with adequate precautions, the first erlenmeyer was disconnected and replaced by the second. 25mL of 15%HCl were added the the addition funnel,

and gassing started again. The take off increased noticeably. Once the second gassing was complete, take off came to a near halt, even with increased

heating. The Cl2 generator was disconnected, and vacuum applied, but only a few drops of distillate were recovered.

Heating and vaccum was stopped, the flask was left to cool a bit. A dark red/orange residu was left, much more fluid than the first one.

50mL of xylene were added, and brough to a boil for 5min. Upon emptying the flask, only a few "burnt" stains were left. A base bath soak removed

them.

The red distillate was placed in a 50mL RBF, and a few grams of sulfur were added. It was connect to the simple distn setup, full aspirator vacuum

applied (~25 Torr), and heating started.

At first, a red/orange distillate passed, so vacuum was cut, the distillate replaced in the still, and a little more sulfur added. Distn was started

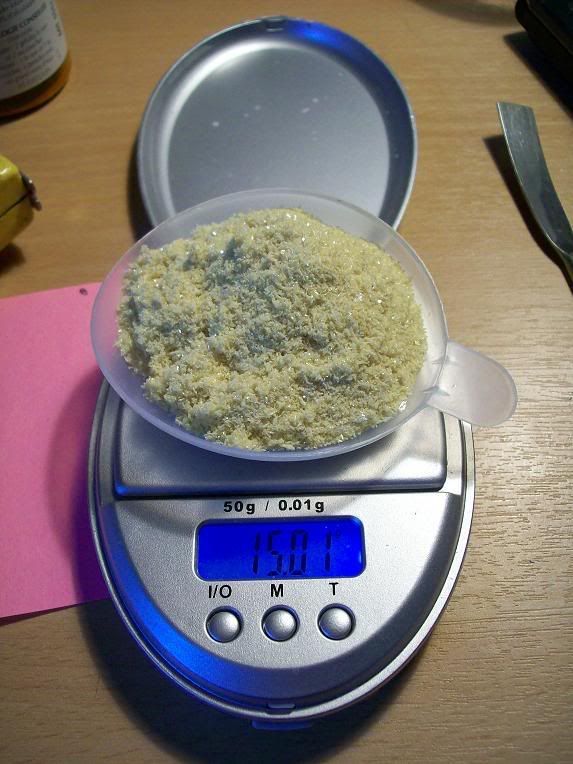

again, and this time a clear yellow distillate passed. It was collected between 51-56°C, giving 22.5g of pur S2Cl2:

The very slight orange tone must be du to the trace amounts of SCl2 present in the distn setup during the second vac distn. The product fumes slightly

in moist air, and smells badly of rotten eggs/ sewers. Hopefully, the smell doesn't last long.

Comments

Although the second attempt was much more succesfull, more Cl2 would surely have produced a better yield. Any produced SCl2 isn't a problem, as it

is reduced to S2Cl2 when distilling over sulfur. Next time, a short coluum will be used.

The yield wasn't calculated, as some of the S2Cl2 comes from the reduced S2Cl2, and it isn't possible to count the amount of SCl2 in the distillate,

or the amount of sulfur remaining after distillation.

So for best yields, this reaction should be done at high temperatures (>200°C, no unreated chlorine), and with healthy (can i use that word for

chlorine?!  ) excess of Cl2. Also, the distillate should have the shortest path

to the condenser, as it is hard to seperate from the unreacted sulfur in the pot, as Garage Chemist explained to me. ) excess of Cl2. Also, the distillate should have the shortest path

to the condenser, as it is hard to seperate from the unreacted sulfur in the pot, as Garage Chemist explained to me.

Many thanks to him for his advice, and for sharing his results in his thread, which was very helpfull.

Details on the use of the S2Cl2 are to come shortly.

[Edited on 16-4-2008 by Klute]

|

|

|

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

To recrystallize from xylene, I suggest you get a very fine metal screen. I believe the ones I located were some sort of car part and had several

round screens crimped together around the edges, with various hole sizes, the smallest barely looking like mesh anymore. The hot xylene (and a small

amount of molten sulfur that was collecting in the bottom of the beaker) flows quickly through the screen and the vast majority of the junk was

excluded. The filter is cooled, scraped off and heated in a small amount of xylene to completely clean it and allow for reuse. After a single run

through the filter, I reheated the sulfur and xylene to redissolve and was able to easily filter through paper.

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

This is an interesting substance and a somewhat politically incorrect one as it is listed in CWC - immediate precursor to sulfur mustard.

But you don't want to go there.

More practically, it reacts with anhydrous NaOAc to give (after thermolysis of the intermediate) Ac2O.

More recently, it was found to react with DIEA (di-isopropylethylamine) in presence of DABCO (diaza{2.2.2}bicyclooctane, or piperazine with an

ethylene bridge across the nitrogens) to give a very interesting product called scorpionine.

The other way to prepare it is to chlorinate CS2 in which case you get about equal amounts of SCl2/S2Cl2 and either CCl4 or CCl3SCl, depending on

wheter you added some catalyst. There is a trick to seperating this mixture. But the bottom line is that you end up with a lot of sulfur chloride

byproduct.

The trick is that you can force all the S2Cl2 to become SCl2 by passing the mixture through activated carbon granular bed at a particular temperature.

The resulting mixture can then be easily fractionated. Otherwise it is a pain in the ass.

Sic gorgeamus a los subjectatus nunc.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Nice work Klute and thanks for the detailed write-up. And BTW that is Len's Cl2 generation procedure (original work by Organikum), not Leu's.

May I ask what is in that lecture bottle with the green label? I am always on the lookout for possible new sources of reagents.

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Sorry for the typo! I evidently meant Len's document

The lecture bottle is a disposable argon cartridge, with a inline CaCl2 dryer. I'm thinking of buying a rechargeable one, as these come expensive

after a while...

Sauron, I have no interest whatsoever in sulfur moustard gas, or in any chemical weapons.

I'm using this reagent to form hydroxydisulfides (see my post in orgchem shortly). Not having CS2, I prefer this route. Apparently it gives a less

complex mixture of substance. And i wouldn't know what to do with CCl4, i have no use for it that i can think of at the moment.

Thanks for the advice regarding the sulfur purification. But I realized my local supplier can sell me 500g of sublimed sulfur for 16E, while i paid

8euro for 750g of dirty 80% gardening sulfur, and 7E for a liter of xylene-containing solvant :S...

|

|

|

PainKilla

Hazard to Others

Posts: 306

Registered: 29-4-2004

Member Is Offline

Mood: No Mood

|

|

I tried this reaction a while back, and I've a few suggestions for future runs:

Try to use a deeper flask, such as a pear, or perhaps something test tube-like. This allows for much better contact (provided you can insert the gas

delivery tube all the way to the bottom) of the gas with the sulfur. In addition, I have found it's very nice to use a reflux condenser in the initial

stages of the reaction... This forms SCl2 but it decomposes to S2Cl2 fairly rapidly anyway. This also improves yield quite a bit, I don't remember

what I got but I think it was at least 75%.

In short: hold sulfur in a pear flask at about 130*C, and run chlorine through it while refluxing. After most of the sulfur has reacted, distill the

mixture and allow to stand to get the S2Cl2, or distill under chlorine to get SCl2.

Hope this helps, and thanks again for the nice procedure and pictures!

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

No, klute, I never thought, or intended to imply, that you have any interest in sulfur mustard. However, here is a hint: do not bubble ethylene gas

through your S2Cl2. Not if you like your DNA the way it is.

My comment was solely to remind that these days the mere possession of S2Cl2 may be seriously misconstrued by national authorities. This may vary from

country to country. If in your country you could buy it, then you are all right. If not, you may be prohibited from making it. Not that this would

necessarily deter you, but, you ought to be aware of what you are doing.

Where I am, I cannot buy or import S2Cl2 without a special MOD license which is unlikely to be granted. Likewise it is forbidden to make it without

same license. And no that might not stop me either. But personally I would not keep it around for long. Same goes for SCl2. And anything on CWC

likewise. You see, that stupid treaty resulted in national legislation in all signatoree countries, varying to be sure. But the bottom line is, they

are paranoid about this. The same with thionyl chloride and thiodiglycol. For same reason, associated with same lethal agent.

You need not be interested in chemical weapons for them to get you in trouble, you see?

Sic gorgeamus a los subjectatus nunc.

|

|

|

DJF90

International Hazard

Posts: 2266

Registered: 15-12-2007

Location: At the bench

Member Is Offline

Mood: No Mood

|

|

Sauron has a good point. Its like the meth situation, you may well own iodine or red phosphorus (or both :O) and have no intention of making any

illegal substance, but thats not how the authorities will see it. As Sauron also said, the restricrions on chemicals vary from country to country

(e.g. In the US both Iodine and Phosphorus are prohibited, whereas in the UK, there is no such legislation). Better to be safe than sorry right?

Other than that, this is an intersting synthesis. And a very well written up one at that

[Edited on 16-4-2008 by DJF90]

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

My intention was not to deter but merely to caution.

I like sulfur chemistry.

Just as I like phosphorus chemistry.

And lots of other things.

These do not equate to chemical weapons.

Anyway for S2Cl2 and SCl2 I recommend Brauer for prep and purfication. The neat procedure for getting a discrete SCl2 free from S2Cl2 is a patent or

two by Rupp and Meyer of AKSO.

One of the hassles with making S2Cl2 and/or SCl2 by union of the elements is that sulfur is very very soluble in S2Cl2 up to some crazy figure like

65% w/w. When you distill S2Cl2 containing lots of S the S tends to coat the inside of the flask, connecting tubes, condenser, etc. as I am sure Klute

has observed. So the solution is to continue chlorination till as much of the original S has been chlorinated as possible. You can follow this by mass

gain, assuming you weighed the S you started with and have a tare on the apparatus.

If any SCl2 is formed, this can be separated by fractionation or, wait and it will disproportionate to S2Cl2 anyway.

The Rupp-Meyer technique for turning S2Cl2 back into SCl2 is the best or else the method recommended by Brauser. But SCl2 is not stable and will

always disproportionate back into S2Cl2.

Sic gorgeamus a los subjectatus nunc.

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Yes, good point actually, I hadn't considered things that way. So thank you for the warning.

But i check the legislation, i have to file a declaration if i start handling more than 100kg per year for 3 consecutive years , which is not going

to happen  . .

In any case, the S2Cl2 was used up like... 15min after having been isolated

When i distilled my crude product with excess sulfur to reduce the SCl2, there was sulfur left only in the still flask. As i distilled some xylene

in the setup after distillation, it cleaned the droplets of product in the setup before it had time to hydrolyze to sulfur. I obtained a yellow

solution of S2Cl2 in the receiver (which smells as bad!), and most of the tarry sulfur residu was dissolved in the hot xylene in the still. The

"burnt" stains left in the flask were removed by a simple soak in the base bath, the rest of the setup came out perfectly clean too.

So after all cleaning sulfur out of glassware isn't that much of a hassle, when you've got a base bath  . .

EDIT: BTW, i didn't even know what the structure of mustard gas was before checking the textes. I was also surprised to see things like tiethanolamine

or dimethylaminoethanol been restricted as weapons precursors.

[Edited on 17-4-2008 by Klute]

|

|

|

grind

Hazard to Others

Posts: 120

Registered: 13-1-2007

Member Is Offline

Mood: No Mood

|

|

The whole procedure can be done in boiling chloroforme, this is much easier und gives excellent yields!

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

Lovely to see someone else doing experimental work! The first part is similar to what ive just been doing - its the third time thats happened with my

posts - must be some form of collective ESP . I didnt have any S cleaning

problems, the reaction vessel had no S in it at all. I believe NaOH marks the glassware - especially the quickfit? Even a 2% boiling solution has

once left a mark on my glassware. . I didnt have any S cleaning

problems, the reaction vessel had no S in it at all. I believe NaOH marks the glassware - especially the quickfit? Even a 2% boiling solution has

once left a mark on my glassware.

In chloroform? Whatever for? The yield is great in just liquid S, why complicate things.

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Thank you Len.

But surely you had some black residu left in the flask?I guess using pur sublimed sulfur would leave much less crap behind, but...

Concerning the base bath: I never have had any etching at all of the glassware, even when i left some in there for 3weeks, the plastic rings got

partially dissolved, but the glass wasn't even slightly fogged. We use these baths at work, and over the years it's been used, the only times etching

were seen was when leaving fritted glass filters for extended periods (>5days). But 12-24H is usually all it takes.

On the other hand, i've noticed etching when forgetting about a beaker with 10% NaOH solution inside, slight evaporation left a crust of NaOH which

left etching traces. Maybe the fact it's in alcohol solution diminishes that effect, because I've often noticed NaOH crust when a bit of glassware

isn't totally immersed, but no etching what so ever.

The use of chloroform could be handy to avoid dirty glassware, but you can't distill the S2Cl2 as it is formed. I'm pretty satisfied with the

straight sulfur also.

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

Ive posted some pics of what I got now. I did have some black residue - but it all disolved in a single EtOH wash, nothing compared to the benzyl

chloride polymer, or sulphuric acid after ether reaction gunk. I think passing Cl2 just past the end point is a good trick.

With NaOH I had small traces left at the liquid line - where it concentrated following the fake benzyl alcohol patent. It seems from what you say

cold alcoholic solutions < 10% should be OK. Mind you H2SO4 and oleum if on hand also clean S mighty fast and with no risk to glassware.

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

When you are only going to chlorinate 15 g or 50 g, why not make life easier and use pure sulfur rather than mucking around with garden sulfur? You

are "saving" pennies and complicating your isolation and purification much more than the "savings" justify.

Sic gorgeamus a los subjectatus nunc.

|

|

|

DJF90

International Hazard

Posts: 2266

Registered: 15-12-2007

Location: At the bench

Member Is Offline

Mood: No Mood

|

|

"Thanks for the advice regarding the sulfur purification. But I realized my local supplier can sell me 500g of sublimed sulfur for 16E, while i paid

8euro for 750g of dirty 80% gardening sulfur, and 7E for a liter of xylene-containing solvant :S... "

I think Klute would have used the pure sulphur if he knew it was available at the time

[Edited on 19-4-2008 by DJF90]

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Exactly

I spent nearly as much money for 500g sublimed sulfur, to get some crap from a gardening store and a bottle of paint remover, out of which i obtained

50g, emptying nearly the whole bottle in the process.. Needless to say, if i will try this again, i will buy the sulfur. I prefer having 450g pur

sulfur lying on a shelf, than 600g of dirty garden sulfur

|

|

|

grind

Hazard to Others

Posts: 120

Registered: 13-1-2007

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Klute

The use of chloroform could be handy to avoid dirty glassware, but you can't distill the S2Cl2 as it is formed. I'm pretty satisfied with the straight

sulfur also. |

Nice synthesis, Klute! Respect!

The use of boiling CHCl3 as solvent has the advantage, that the reaction is fast enough at 60°C (no need of high temperatures) and gives a very pure

(slightly yellow) product. Overchlorination is completely avoided when letting always an excess of sulfur in the solution, this increases the yield

and facilitates purification. When cooling down the mixture of CHCl3/S2Cl2/excess S, very beautyful, really big, clearly structured and glistenig

crystals of sulfur separate from the solution.

And of course, the cleaning of glassware is easier, that´s right, Klute.

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

So the sulfur is soluble in hot chloroform? Do you solubilize all the sulfur at the beggining of the reaction, or just let it gradually dissolve as

S2Cl2 is formed?

I guess all you need to do is filter the ecess sulfur, remove the chloroform, et voilà. Could be worth a try after all. Have you tried this

yourself? ( i suppose so) how long do you chlorinate?

|

|

|

LSD25

Hazard to Others

Posts: 239

Registered: 29-11-2007

Member Is Offline

Mood: Psychotic (Who said that? I know you're there...)

|

|

From Brauer, pages 371-2:

| Quote: | Sulfur is melted in a flask equipped with a side arm and a neck elongated into a gradually narrowing tube. By tilting the flask, the walls are coated

with a uniform layer of sulfur melt. After cooling, the flask is mounted vertically in such a way that the tube end passes through a rubber stopper

into another flask below. From the latter, a gas outlet tube passes through a drying tube directly to the hood. A moderately rapid stream of carefully

dried Cl, is introduced through the side arm of the top flask and the walls of that flask are simultaneously heated to 50-80'C by fanning with a

flame. Once the reaction is in progress, the S2Cl2, product flows into the lower flask in a rapid succession of drops. The orange-red substance is

still contaminated by dissolved starting materials.

Some sulfur is added and it is distilled at atmospheric pressure. The portion which distills above 137'C is refractionated over sulfur at about 12mm

in an apparatus with ground glass joints, b.p. of the pure product is 29-30C at this pressure... |

Might be worth a shot? Klute, once again, nice...

Attachment: SulfurChloridesfromBrauer.pdf (1.4MB)

This file has been downloaded 898 times

Whhhoooppps, that sure didn't work

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Thanks for adding this, but i think the temperature would be too low to distill the product as it is formed, with the setup i used, considering i had

to heat somewhere between 200-300°C to get it going..

I think i would follow Len's direction if i try this again, he managed to do the reaction in better yields and shorter time, and has kindly provided

a very detailed report on it.

But considering the tough work with the product disulfide made with phenols, until i get some commercial silical gel to purify those damn viscous

disulfides, i working on TEMPO synth (yes, i am pissed off  ) )

|

|

|

LSD25

Hazard to Others

Posts: 239

Registered: 29-11-2007

Member Is Offline

Mood: Psychotic (Who said that? I know you're there...)

|

|

No, from what I understand, the idea in Brauer was not to distill the product off as it formed, but rather to allow gravity to remove it from the

scene. From what I can visualise, the easiest way to work around this would be to coat the walls of an erlenmeyer shaped filter flask with molten

sulfur, leaving the vacuum side-arm free. Invert it so that any liquid formed runs down into your distillation vessel (probably an idea to fabricate

some sort of seal here), then pass dry chlorine gas into the inverted vessel via the side-arm. This removes the crude product from the excess sulfur,

which is then mixed with a small amount of excess sulfur and distilled from the distillation vessel.

PS would it be easier to liberate a little RP from matchbooks and use that to make the SCl2 which then degrades to the monochloride?

Whhhoooppps, that sure didn't work

|

|

|

grind

Hazard to Others

Posts: 120

Registered: 13-1-2007

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Klute

So the sulfur is soluble in hot chloroform? |

I think the sulfur is only very slightly soluble in boiling CHCl3.

| Quote: | | Do you solubilize all the sulfur at the beggining of the reaction |

No.

| Quote: | | or just let it gradually dissolve as S2Cl2 is formed? |

Yes.

| Quote: | | I guess all you need to do is filter the ecess sulfur, remove the chloroform, et voilà. |

No. That gives only a mixture of S2Cl2 and a lot of dissolved sulfur. Distillation is necessary.

| Quote: | | Have you tried this yourself? |

Yes.

| Quote: | | how long do you chlorinate? |

I don´t no exactly anymore, I think 6 hours (+/- 2 hours) for 200 g sulfur? The chlorine gas was made from MnO2 and HCl and dried with conc. H2SO4.

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

I have read the procedure in Brauer, and similar preps cropping up elsewhere, which I think are all copies of the one original. I cant see this as a

serious preparation, except perhaps as a demo.

1) The reaction normally does not start spontaneously

2) Warming the S deposited on the walls can easily result in the S melting

3) As the S2Cl2 is formed it drips down carrying dissolved S with it. Getting rid of the S2Cl2 by distillation not only shift equilibrium to right

it minimises the amount of S that can be carried away - as it now had to be carried by the vapout phase. The almost perfect S2Cl2 stoichiometry this

setup gives I think is a confirmation of this

4) You cant get very much S deposited on flask walls - it has to be a thin layer, so its very scale limited.

|

|

|

|