| Pages:

1

..

9

10

11

12

13

14 |

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by Xenoid

@ Rosco, I will have to try Sb for the moment and even that is proving difficult. I wont have any Bi till the new year!

Regarding the 4 - coat Co spinel anode chlorate cell. It appears to have produced a considerable amount of chlorate. I put a few mls of solution in a

test tube and added a little saturated KCl, there was immediate fine crystalline precipitation. I put it in the fridge and the solution is now about

half crystals...  |

@Xenoid , that's a good deal , it's snowing chlorate

The Co spinel has useful properties in at least three different schemes , which happen to be the same three schemes that are being applied here , and

that's no coincidence , it's an integrated system being conteplated .

It's when the three schemes converge that longevity

and efficiency should result . Up to this point your experiments are really preliminary tests which reveal promise for the larger scheme working . So

far so good .

A quick OTC source for Bi may be fishing sinkers , egg sinkers up to 3/4 ounce are in some stores . I still have to get some Mn and do the improvised

method on that for

nitrate . Regarding the Sb , antimony can actually have some catalytic effect alone and can also act as a dopant on the bismuth , but my educated

guess is it is likely the bismuth that will be the principal active catalyst component in the outer coating , but the Sb will be a good

included component in the system for other reasons.

And Bi is known to work with lead , US4101390 shows

87% curent efficiency for chlorate and also claims good perchlorate efficiency with very small catalytic amounts of Bi added to PbO2 . I believe it

is a parallel with the baked MnO2 anode of US4072586 ,

only the method of dispersion would be different for the

baked MnO2 anode . That was why the 50nm Bi2O3

gotten on reflux overnight at 100C caught my notice .

I am not sure about the thermal properties , so a different method may be required , but it may be possible just to add the Bi2O3 nanocrystalline

material as a thixotropic

component to your final baked coating , and bingo you

should have a catalytic anode coating with high selectivity for chlorate / and perchlorate . Hopefully 90% current efficiency can be achieved on the

perchlorate from chlorate , and it should be correspondingly good for

the other stages up from the chloride as well .

There still needs to be an SnO2 sealing layer over the spinel interface . I am positive on that . But the sealing

SnO2 over spinel should be a no fuss SnO2 since it

is only a sealing layer and not some multipurpose

coating having to be handled some special way ,

as when the interface has not been already resolved .

Even if the Bi-Pb electrodeposition ended up being the

outer coating , that coating is very thin and should not

be any laborious plating .

What the idea is with this sandwich layering is to

put the best materials to work at what they do best ,

instead of trying to make one coating that can't do it all

be multi-tasked to destruction trying to do the impossible .

The layer system system I have been contemplating

works as follows :

The hydrided substrate is stable up to ~200C .

The spinel is a superb interface and anti-passivation

material which takes the handoff on baking from the hydride , and anti-passivates the Ti creating a stable though not yet perfectly encapsulated

substrate .

SnO2 hermetically seals that spinel coated substrate .

And then the working anode coating complete with catalysts goes on the outside .

If that is a repetition of what I said before , sorry

I lost track . I am going to request some references

to better pin down the final details on how to use

the Bi in the baked coating scheme . I'll get back

with those references later .

Edit: See attached article

Synthesis of bismuth oxide nanoparticles at 100 -C

[Edited on 18-12-2007 by Rosco Bodine]

Attachment: Synthesis of bismuth oxide nanoparticles at 100 -C j.matlet.2005.03.037.pdf (116kB)

This file has been downloaded 8836 times

|

|

|

chloric1

International Hazard

Posts: 1147

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Rosco, thank you for the bismuth info especially since I am not a university student right now and have no journal access. So you advocate bismuth

doped lead dioxide? Since you cannot pyrolize lead nitrate to its dioxide would it not be prudent to disperse the already prepared lead dioxide

powder in concentrated bismuth nitrate to put over the Stannic oxide sealant? Or should the working layer be another cobalt spinel coat with the

catalyst mixed in? The number of parameters is increasing in orders of magnitude with this discussion. I only have two titanium rods to work with

and I am trying to decide which nitrate precusors to prepare. I know I shouldn't repeat Xenoids work exactly but I really wish to get a "feel" for

the cobalt spinel alone for myself. I may have a novel perspective or maybe my experience will only further confirm Xenoids results.

Fellow molecular manipulator

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by chloric1

Rosco, thank you for the bismuth info especially since I am not a university student right now and have no journal access. So you advocate bismuth

doped lead dioxide? |

Yeah I think it is significant that the Bi has come up in several

different perchlorate specific anode designs , as a catalyst .

It seems pretty likely either to function via some bi-electrode

couple or it may possibly be an active catalyst by itself . | Quote: |

Since you cannot pyrolize lead nitrate to its dioxide would it not be prudent to disperse the already prepared lead dioxide powder in concentrated

bismuth nitrate to put over the Stannic oxide sealant? |

I am open to any suggestions or theories as to the

mechanisms or the various proposed schemes for getting the Bi into the baked coating .

There is going to be diffusion on baking among whatever form precursors are used , not only within the outside layer

but between the layers . It is something like the way an automobile tire is made from layers that are then heated

and fused together into a unitary structure having embedded

components , with the Bi here will be like "snow studs" and

perhaps some of the "tread" layer , where the rubber meets the road .  The

"snow studs" in this analogy would be distinct 50nm microcrystals , like a speckled egg or sand in The

"snow studs" in this analogy would be distinct 50nm microcrystals , like a speckled egg or sand in

wet paint , a separate phase , but having those particles

diffusion bonded into the composite , like tiny icebergs in a frozen sea .

I have some imaginings what it might look like if you could

climb into a tiny nanospacecraft and descend to take a look

http://www.youtube.com/watch?v=wpLNsdbOPPs&feature=relat...

| Quote: |

Or should the working layer be another cobalt spinel coat with the catalyst mixed in? |

Going by Xenoids experiment with the MnO2 over cobalt spinel , we know the outer layer is at least 85% MnO2 ,

and can then attempt to extrapolate the percentages for

the remaining materials , via solid solution parameters

which would seem likely to produce the envisioned effect .

The percentages are probably not critical for getting something that will work . These catalytic coatings are

something of an art , as would be used for finish glazes

on decorative ceramics . It is down to a point where it

becomes tweaking the system by observed effects which

produce the final touch .

| Quote: |

The number of parameters is increasing in orders of magnitude with this discussion. |

It may be possible to combine some of the functions of the separate layers into one coating mixture , I'm not sure .

This scheme should work with some variation within

certain limits .

| Quote: |

I only have two titanium rods to work with and I am trying to decide which nitrate precusors to prepare. I know I shouldn't repeat Xenoids work

exactly but I really wish to get a "feel" for the cobalt spinel alone for myself. |

Yeah it doesn't really progress things to reprove what already is established , but it doesn't hurt anything .

What would seem to be the next logical step to me would

be to do the hydriding and baked spinel interface , one coat only up to perhaps four coats of spinel , ( Xenoid has the eyes on location sense about

this ) and then try a simple

oxidative soak deposition of plain hydrated SnO2 gotten from

SnCl2 + NaNO3 , and then bake that to seal the spinel interface . Alternately an ammonium stannate dip and bake

would seem a good bet . No doping is really needed because

the doping should be picked up by diffusion from the spinel

layer , when the SnO2 is baked . If this does not occur as

anticipated then some sort of doping can be applied externally after baking as a subsequent diffusion from

the top , via a dip in SbCl3 followed by baking or by using

a doped stannates mixture , doped with Sb or Co nitrate ,

or both together . Or letting diffusion from a doped subsequent layer following such schemes do the job ,

or yet again by using the original mixed chlorides ATO

precursor ...all of these schemes would probably work .

But you see the corrosive schemes using chlorides becomes

a last resort rather than the first choice . And definitely

no heavily doped SnO2 layer is needed , nor desired .

| Quote: |

I may have a novel perspective or maybe my experience will only further confirm Xenoids results. |

Heck I trust Xenoids results already , and no real surprises there except it works even better than expected

So I want to look at the 7:3 cobalt-nickel spinel interface

but by the time I get around to it , it will already be done

probably by Twospoons , IIRC . I can't help the delays ,

as I have a plateful of other stuff that keeps me at a

distance , and this is like the model airplane that goes

together a piece at a time , over many months where I

can take a few minutes here and there , to apply to the build . You fellows are three months ahead of me on implementation , but I have also been

scrounging the references as well as the hardware . If this works out , maybe patent the anode and let the proceeds act as a trust for this forum ,

to keep the site going in perpetuity . In a way it is already public domain , but in another way it is ultimately Polverones , for indulging us in

such pursuits . Call it a work for hire where we worked for peanuts , if it doesn't turn out to be just another back to the drawing board scenario .

Given the sad state of affairs for science in the schools ,

this waterhole needs to kept a well in the desert long after we are all gone as a legacy .

[Edited on 18-12-2007 by Rosco Bodine]

|

|

|

chloric1

International Hazard

Posts: 1147

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Rosco you really said it. I am quite optimistic though. I mean we came this far in just 2 or so weeks after YEARS of lead dioxide setbacks. There

are many unresolved home chemistry issues to crack but this perchlorate one is a biggy. So let us crank it out hard and heavy. If I can pull off

getting back to school and into a chemistry program, I will need this forum more than ever. I knew in the late 1980's that the established education

system would water down about any love or enthusiasm for the field of chemistry so I studied other things. Turns out my career path was in error and

I decided I should only do what I really love and nothing else. This forum will keep me "awake" so I don't lose my way.

Fellow molecular manipulator

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Yeah this forum is a quite unique and a valuable resource

for brainstorming , an informal think tank of sorts ,

some small comforting sanctuary for thinkers and experimenters .

My reference mining for bits of useful information is not really producing any significant search hits anymore

and I am getting crosseyed from reading the more general

long lists of hundreds of more vague sorts of search results trying to find anything more . So it is probably time

for me to close the search for more unless some new parameter for possible search hits occurs to me .

The spinel I think really is the most promising interface

because the conditions required for getting it right are

fairly easily reachable , moreso than alternatives .

The sealing layer of SnO2 also is simplified .

The outer coating and getting the selectivity for good

efficiency for a perchlorate anode is where the technical difficulty arises , because the "recipe" for that *special*

baked coating is not well specified . So here comes the experiments , and reverse engineering by guess and test .

However , the Bi + PbO2 electrodeposited perchlorate

anode coating is well detailed and is one of the thinnest platings that is advertised to work well and have good

service life . No guessing there .

So there really is no good reason to get overly discouraged about the uncertainties concerning the outer layer where a baked coating there is

desirable ,

because even if a very good one is never found ,

there is still the old standby electrodeposited coating which should work , and being a thin layer deposit

could be just fine .

IMO , either way it goes with the wearing coating ,

the overall system is still more easily implemented

and more likely to work well for a long time , than

alternative schemes . Anyway ...it's different

Now , I think I'll take a break , need some downtime .

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

Gertrude the Anode

For the moment I have given up trying to produce a soluble Sb compound which would be suitable for doping the MnO2 coating of "Gerty" in a suitable

quantitative fashion. I have thus left this aspect of the anode layering process until my Bi arrives in the new year.

In the mean time I have decided that there is no point in doping the MnO2 if it doesn't hold up well in plain form in a (per)chlorate cell. I have

therefore decreed that "Gerty" shall be subjected to that form of Hell that masquerades as a perchlorate cell. But first I will add another 6 coats of

MnO2.

Since I now have some isopropyl alcohol, I decided to mix some with the Mn nitrate in the fashion of some of the patent "recipes". Each of the six

coats, used a different solution and/or procedure. Without going into detail at this time, there appeared to be little difference in the efficacy of

the 6 methods. The isopropyl alcohol increased the loading, but this just meant some of the coat rubbed off when polished between coats. Part of the

problem is "Gerty's" glossy, enamelled coat, no liquid wants to adhere smoothly to it. It forms runs and droplets, which when baked produce a thicker,

crusty coat, this tends to rub off. I even resorted to using a few drops of an agricultural spray penetrant on the last coat, but even this had little

effect.

The additional coats were baked on at 350 oC. +/- 10 oC., I had planned on going as high as 380 oC. but the heat gun wasn't up to it today (must have

been high electricity load in the area).

Gertrude was introduced to a "new" test cell with dual cathodes to even up the current density. I have started the run with a conservative 25mA/cm^2

(0.5 amps) at 3.5 volts. Immediately the current was turned on large bubbles formed and there was a swirl of "permanganate" purple. This ceased after

a few seconds, and the bubbles decreased in size (I guess as the surface roughs up).

The cell has been running smoothly now for 5 hours, on constant current mode (0.5 amps) and the voltage has slowly dropped to 3.3 volts. The cell has

a slight rosy tinge (which seems constant), more typical of Mn(II) rather than Mn(VII). There is a slight amount of "black scum" around the meniscus.

Unfortunately, a methylene blue test does not indicate the presence of perchlorate yet!

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

Some of the articles for DTO going onto Ti have heated the Ti up to 480C or so (decomposition temp. of the Tin Chlorides) and then sprayed on the DT0

precursor. Might work for the Mn if you put the precursor in a perfume bottle (the one's you can refill) and spray onto hot anode to stop the problem

of the precursor not wetting the anode. It will dry instantly.

You could mix precursor half and half with perfume to keep Gertude sweet too

My two Cobalt Oxide anodes that I was testing in Chlorate cells failed some days ago. The one with the ligher coating failed one day, approx. before

the one with the heavier coat.

Dann2

[Edited on 23-12-2007 by dann2]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

We know what reportedly wets anything including teflon

is the mixed valency tin chlorides polymer of US3890429 . Situations like this would seem like a good place to put it to use .

Other good anode names are of course Lola and Bertha ,

Dolly and Mabel and Elvira

[Edited on 23-12-2007 by Rosco Bodine]

|

|

|

chloric1

International Hazard

Posts: 1147

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

| Quote: | Originally posted by dann2

You could mix precursor half and half with perfume to keep Gertude sweet too

{quote]

Dann you are a card!   But no seriously, I feel your observation is quite sensible if you

cannot get good wetting. After all, when Gerty was first made, the Ti rod was etched providing a workable surface for the first coatings. And the

manganese just morphed into the cobalt oxide coating. But no seriously, I feel your observation is quite sensible if you

cannot get good wetting. After all, when Gerty was first made, the Ti rod was etched providing a workable surface for the first coatings. And the

manganese just morphed into the cobalt oxide coating.

@Xenoid- I was sure that Gerty was going to be a good performer. If not a good perchlorate maker at least a decent MMO for long term chlorate making

use. It seems that the manganese might not be stable enough on its own. Or maybe you should start with NaCl brine and try all the way to

perchlorate. Personally, I don't understand why you are getting manganese leached into your solution unless the manganese was not completely

decomposed. Maybe a longer bake time might help.

@Rosco-IMHO these silly names might actually have scientific value in these quest or ours. These would serve as simple identifiers to anodes made by

specific methodologies in a certain sequence. Provided an accurate and complete discription is available from the start the contents and properties

of said anode would be understood in the forum when me, you, Xenoid, or someone else says Bertha gave up the ghost in 5 days in brine. I have a four

day weekend and am hoping to turn out at least one anode. The name I am considering is Dorothy.

[Edited on 12/23/2007 by chloric1]

[Edited on 12/23/2007 by chloric1] |

Fellow molecular manipulator

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

| Quote: | Originally posted by chloric1

@Xenoid- I was sure that Gerty was going to be a good performer. If not a good perchlorate maker at least a decent MMO for long term chlorate making

use. It seems that the manganese might not be stable enough on its own. Or maybe you should start with NaCl brine and try all the way to

perchlorate. Personally, I don't understand why you are getting manganese leached into your solution unless the manganese was not completely

decomposed. Maybe a longer bake time might help.

|

Update on Gertrude: After 20 hours, electrical parameters are stable, the slight rosy pink ??Mn(II) colour has faded, I think it may have oxidised to

MnO2 as there is a little black on the bottom of the cell, black MnO2 from the meniscus has largely disappeared as well!

I will check for perchlorate at at 24 hours, and also increase the current density to 50mA/cm^2.

Re Naming: Lets not be sexist about this. I am about to clone Gertrude in a male form (Hubert). Hubert will be placed in a chlorate cell and tested to

destruction...

Also the anode description protocol used by R.P.Wang is usefull, list the anode components outwards, perhaps adding a number for the number of coats.

In this system, Gertrude would be:

Ti/2xCo3O4/14xbetaMnO2

[Edited on 23-12-2007 by Xenoid]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

You're working with rods, right? A male name would generally make more sense then. Freud would agree.

Tim

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Uhhhh ...... Tim , it's not the rod itself that is the primary interest here , but rather the processes and most satisying

coatings applied thereon  , you know , what sort , , you know , what sort ,

how many times ...how hot , .......the benefits of threesomes in coating sequences , endurance , and so forth  You just need to broaden your perspective . You just need to broaden your perspective .

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Ah, true...

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

Gertrude makes perchlorate.

Update on Gertrude and her adventures in a perchlorate cell.

Well to cut a long story short, I completely messed up the testing procedure!

1) I carried out the testing with what I thought was saturated NaClO3 solution, but after carrying out some density measurements (1.22) it was

actually only 354g/L or only ~ 106g NaClO3 in my 300 ml test cell.

2) About 1/3 the way through the run, I decided there was "something wrong" with the solution, I thought perhaps it was NaCl. I won't go into my

reasons for this, but suffice to say I changed the electrolyte. As it turned out, to exactly the same concentration and composition.

3) I varied the current density 3 times, starting at about 25 mA/cm^2, increasing to 50 mA/cm^2 and finally increasing again to 75 mA/cm^2. These were

carried out at approximately 24 hour intervals.

4) My initial fears about "Gerty" not producing perchlorate were totally unfounded. She has produced copious quantities, there was a problem with the

methylene blue test (see below). If doping with Bi improves perchlorate production that will be even better.

5) I added two "lots" of unweighed solid NaClO3 crystals, during the testing, so the true amount present is any bodies guess!

Basically Gertude has run for the equivalent of 76 Amp hours in a low NaClO3 concentration perchlorate cell (see attached image) at the above

mentioned current densities. Unfortunately she has not come through unscathed, although still appearing "as new". The presence of purple permanganate,

and black precipitate indicates the anode has eroded, how much, I'm not sure. Much of the detritus in the cell has turned out to be erosion products

from the SS cathode (especially from the head space area). As I pointed out elsewhere, if you want a clean running cell (chlorate or perchlorate) use

Ti cathodes.

Methylene Blue (MB) testing:

When running previous Pt based perchlorate cells I have never had a problem with this test, an intense violet ppt. is formed. This holds true for the

Li perchlorate cell I am currently running, as well.

With this "Gertrude" based cell, however, my first 3 or so checks produced negative results. Finally in desperation I added a few grains of NaOH to

ensure the solution was alkaline, before adding the MB, this resulted in an immediate violet ppt. I was confused by this because Dann2's pages mention

perchlorate cells drifting alkaline. I then attempted to check the pH of the cell. I don't have a pH meter (I have now ordered one) so I used some

fish tank indicator. I think this is bromophenol blue in a pH=6 buffer solution as it is a yellow colour. When added to the electrolyte the indicator

went a bluish green then in a few seconds turned yellow indicating a pH around 5 - 6. Thinking this was a little strange, and that there was perhaps

some bleaching action, I boiled the solution but this made no difference. A check with the indicator in the Li perchlorate electrolyte gave an instant

pH ~= 5 indication. Subsequent tests showed MB gave positive results for K perchlorate in a solution acidified with 5% H2SO4. MB gives negative

reaction to weak permanganate solution.

A diluted solution of electrolyte from the "Gertrude" cell gave a yoghurt ppt. with saturated KCl.

So a couple of questions:

1) Why are both the "Gerty" electrode cell and the Li perchlorate cell drifting acid instead of alkaline?

2) Why the unusual reaction to the indicator, by the "Gerty" cell?

3) Why a negative result for MB in an acid solution for the "Gerty" cell when MB clearly works down to at least pH = 4

I have now restarted "Gertrude" at 1 amp (50mA/cm^2) and 4.0 volts in a fresh NaClO3 cell of density = 1.39, this corresponds to a 46% solution (near

saturated) and 192g in my 300 ml cell.

At 100% efficiency 96.8 amp hours are required to convert this to perchlorate.

At 50% efficiency 193.6 amp hours are required to convert this to perchlorate.

Sorry for the long post, but I was typing it up for my own notes.

Edit: Whoops! The blue pen mark next to the anode indicates the approximate electrolyte level. There is no obvious erosion line on the anode!

[Edited on 26-12-2007 by Xenoid]

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

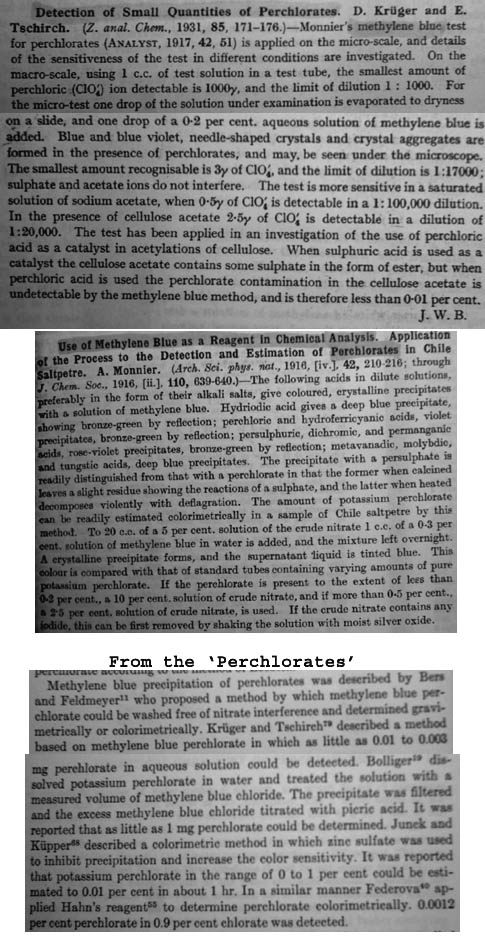

Methylene Blue and pH Drift

I've done a little sleuthing on Methylene Blue, here is a useful reference, it also lists several other species which produce coloured ppts. with MB:

http://www.orcbs.msu.edu/chemical/resources_links/contamhood...

A few things worth noting, which are are contrary to what I have been led to believe elsewhere, are the following;

1) Titanium nitrate produces a blue precipitate, but not nitrates in general. In fact methylene blue was used to detect perchlorate in the Chilean

nitrate deposits!

2) A practical detection limit is .001 M perchlorate, this corresponds to about 0.1 g/L

3) Concentrated perchloric acid (ie. 70%) destroys the reagent, but the test can still be used on the diluted acid (so clearly, acidic solutions are

OK)

With regard to pH drift, I recall noticing a scaley white encrustation on the Ti cathodes of the Li perchlorate cell. They didn't easily dissolve when

I rinsed the electrodes. On examination a few days later, they have absorbed water and dissolved away. I assume this was LiOH, it has a relatively low

solubility (15g/100g) and has formed in a similar fashion to Ca(OH)2 in a CaCl2 cell. Removal of OH- in this manner would cause the electrolyte pH to

drift lower.

The SS cathodes of the "Gertrude" perchlorate cell have a hard brownish coating and some of the brown "crud" which has formed may be the "hydroxide"

manganite, which is gamma-MnOOH. Though given the amount of "available" Mn on the anode, it's hard to believe there would be enough to form compounds

which alter the pH substantially.

Anyway, all this still doesn't explain why MB is giving an initial negative result with this particular cell.....!

[Edited on 27-12-2007 by Xenoid]

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

Some info I have on MB testing enclosed.

It mentions Nitrate 'interference' in the stuff out of the 'Perchlorates' (book) but I do not know exactly what they mean.

The presentation is very nice>>>>>>.

Dann2

[Edited on 27-12-2007 by dann2]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Combined coating / sealing strategy

Earlier in response to chloric1 I mentioned that some of the elements of what seems to be a complex coating scheme

might be integrated in some way to simplify things . So here

is an idea which may work fine in that regard .

There remains in my estimation a usefulness , possibly even a necessity for the SnO2 component being involved in these

layered coatings , only I believe it can be better implemented

in other ways than by use of the strictly SnCl4 or Sn+IV alcoholate(alkoxide) based schemes .

The Pytlewski patent US3890429 describes the mixed valency polymer forms of colloidal SnO2 which may be formed as higher precursors for the desired

SnO2 baked coating , even though the patent does not specifiy this end use . Clearly the chemistry of these inorganic polymer forms of SnO2

*spotlight* such materials as being of *great interest* as precursors for baked coating schemes , because of their structure and properties ,

including being capable of being doped at a molecular level with other selected metals of particular interest , like Sb , Co , Ni , and Bi . The

ability of the polymer

to form a dried , persistent and highly adherent film of

1000 Angstroms thickness , even *without baking* , a film having a *profound* hydrophilic character , yet will not simply wash off the surface , but

which acts as a residual

"wetter-sticker" for causing other aqueous systems to

sheet evenly across the surface , is a remarkable property .

Further , the chemical composition of the inorganic polymer

is such that upon being subjected to baking temperatures ,

it fully dehydrates and forms the desired doped tin oxide ,

with its doping either derived from included dopants introduced in its molecular structure in advance , and/or

securing its doping by diffusion from adjacent coatings ,

below , above , or both .

It would therefore seem possible to form the Co3O4 spinel

interface concurrently with a DTO sealing effect , and perhaps to enhance the quality of that spinel layer , by

using the SnO2 inorganic polymer as a wetting agent .

The SnO2 polymer could be applied directly to the freshly hydrided Ti , and simply dried , and then the Co(NO3)2

applied and baked . Each subsequent coating of spinel

could be preceded by a dipped and simply dried on film

of the polymer wetting agent . It would serve to even the wetting out for the Co spinel precursor , and then fuse

together with it on baking , sealing and bonding the grain structure .

Alternately , the initial cobalt spinel interface coating

could be applied as already proven , and the SnO2 polymer

used as a "dip and dry" treatment ahead of the second

and every other subsequent baked coat of spinel . It should work either way . And the wetting out ability of the SnO2 polymer should be especially

useful as a remedy for the

wetability problems which arise later with the MnO2 .

Not a half bad idea huh ?  It works on paper anyway It works on paper anyway

[Edited on 28-12-2007 by Rosco Bodine]

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

Making Hubert

Hubert is Gertrudes big half-brother!

Surface preparation and etching:

The Ti rod was run in a drill press, and sanded with 80 grit garnet paper for 1 min. and then 100 grit paper for 1 min.

The rod was then etched in hot concentrated (290 g/L) hydrochloric acid for about 10 mins. I do this by placing the rod in a test tube containing just

enough (about 1/2 full) HCl that the level rises to the top of the tube. The tube is placed in an empty 400 ml beaker on a hot plate. Eventually H2

bubbles will be evolved from the shiny Ti surface and it will turn dark grey. The HCl will turn pale violet or mauve. The rod is then well rinsed with

distilled water.

Co3O4 (spinel) interface coating:

A test tube was about 1/2 filled with an ~ 50% solution of cobalt nitrate hexahydrate. This was made by dissolving 20g of moist crystals in 20 mls of

water. This solution is dark red. The etched portion of the rod was dipped in the solution for 15 secs. and wiped against the inside of the tube as it

was slowly withdrawn. The drop of liquid usually adhering to the end of the rod was absorbed on a piece of paper towel. The rod was hung in the

previously described heat gun arrangement(see page 3. of this thread), and the heat turned up to 380 oC +/- 10 oC. The heat was maintained for 10

mins. (Use an egg timer or similar!). The heat setting was then turned to minimum and the hot air cooled down to about 50 - 60 oC. At this point the

gun was turned off and the rod allowed to cool further for a few mins. The rod was then removed by its wire hanger (careful it's still very hot) and

wiped lightly with a soft cotton cloth to remove any loose material or "crusty" build-up. Mark off one coat with a tick on a piece of paper (don't

forget this, it's very easy to lose track). The rod is then cooled to room temperature by walking around waving it. In the case of Hubert this dip 'n

bake procedure was repeated 3 times more, for a total of 4 coats.

Beta-MnO2 over coating:

A test tube was about 1/2 filled with a 1.2 M solution of Mn(NO3)2 which had been stabilised with a few drops of nitric acid. The solution is a pale

pink-rose colour. The rod was dipped in this solution and baked in exactly the same manner as outlined above. This coating procedure was repeated 10

times. After the last coat had "baked" for the allotted 10 mins. the rod was baked for an additional 30 mins. at 380 oC. After this the rod was slowly

cooled down over a period of 30 mins. by slowly decreasing the heat gun setting.

The main differences between Hubert and Gertrude are;

1) Co3O4 baked at 380 oC versus 370 oC

2) 4 coats of Co3O4 instead of 2

3) beta-MnO2 baked at much higher temperature of 380 oC

4) 10 contiguous coats of beta-MnO2

5) rod was annealed, by slowly lowering temperature at the end

Using the secret coding system known only to the Fraternity of Anode Fabricators;

Gertrude = Ti/2xCo3O4/14xbeta-MnO2

Hubert = Ti/4xCo3O4/10xbeta-MnO2

To obtain the higher temperatures used for Hubert, I placed tape over two of the air inlet slots on the heat gun.This slows down the air flow, and

meant I could reliably achieve 400 oC.

This coating system is loosely based on US Patents; 4072586, 4265728, 4366042, and 4368110

The image shows Hubert with the simple wire jig used for hanging him in the heat gun tube

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

@ Rosco

The main problem for me at the moment seems to be the slow degradation of the MnO2 coating. Gertrude has now been put in a new saturated perchlorate

cell and seems to be behaving well electrically, but the MnO2 coating is breaking down physically. The cell is colourless, but there are specks of

black ?MnO2 increasing all the time.

Perhaps Hubert will solve this, with his higher temperature baking, time will tell ..

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

You should try what I am suggesting for the SnO2 if

you have the materials available . I have plenty SnCl4

and SnCl2 and Sb2O3 , but no Mn nor Bi compounds .

( still collecting components )

I did a pretty extensive survey of the literature ,

and it seems I am getting resistance to "off label use" suggestions  ( which

is *exactly* my forte ) . ( which

is *exactly* my forte ) .

When old Rosco spots a potential off label use for

something , he has a pretty good record for being right .

I see what you are running into there and I am trying to

tell you what might fix it . You mentioned using an agricultural

wetting agent and this is the same idea , only using something better suited for the task . The film produced

is however very thin , and a more substantial amount of SnO2 will probably need to be used also to accomplish the sealing to a maximized extent . It

will depend on how loaded

with solids the mixed valency sol can remain stable on evaporation and concentration whether it can suffice alone

as the precursor for SnO2 . The nitrates also form the Pytlewski polymers . The anomalous case of tin nitrate combined with iron , aluminum , or

chromium nitrate to form a highly concentrable "hydrogel" as was described in that hundred year old reference which I attached earlier , is very

likely a nitrate based Pytlewski polymer which would work in this scheme as it is a highly concentrated mixture .

If a different polymer mixture does not form a stable , highly loaded dispersion , then another sol or ammonium stannate or some other SnO2 precursor

may be required also . This might mix with the polymer or be applied separately as a second dip .

Probably the technically simplest approach to adding thickness for the SnO2 layer , after an initial coating with the polymer wetting agent , is

simply to use the oxidative cold soak deposition of SnO2 from a SnCl2 + NaNO3 solution .

It is slow but sure .

BTW , I have some nickel carbonate now to go with my cobalt carbonate ....and have some type K thermocouples

on the way . Still need a heat gun , been looking at

the Makita thermocouple gun .

Some of the lead free solders that aren't the 95/5 Sn/Sb

but are silver bearing , may also have some Bi , a few percent .

Putting some MnCl2 or Mn(NO3)2 into the electrolyte

as a deliberate contaminant , additive might help protect the anode via common ion effect . Also using a bit of carbonate 5-10% along with the

nitrate and baking

a bit hotter like you are doing could help . Also

using ~5% of the Co nitrate along with the Mn nitrate

could help , with or without the carbonates . But I think

the inclusion of SnO2 will do a lot more good .

[Edited on 28-12-2007 by Rosco Bodine]

|

|

|

chloric1

International Hazard

Posts: 1147

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Well, I am open to SnO2 polymer sols. I was hesitant at first since they seem a little fickle compared to cobalt spinels. At least until you posted

a patent on mix valency tin with PVA. That immediately caught my interest as I imagined an organic matrix supporting the inorganic oxide. I know the

PVA will not survive the heat but what a cool wetting agent I just might order

some soon since I have not played with it since highschool 17 years ago! I have also read about PVA as a binder for cermics prior to firing but which

ones I don't know. I just might order

some soon since I have not played with it since highschool 17 years ago! I have also read about PVA as a binder for cermics prior to firing but which

ones I don't know.

Fellow molecular manipulator

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

That was a mixed ammonium stannate / ammonium antimonate composition rather than a mixed valency polymer sort of composition which used the PVA

thickener . You are talking about US6777477 , right ?

However that patent did show the production of a precursor which is also of interest in other ways ,

such as for the making of tin(IV) nitrate  . When . When

the tin(IV) chloride is neutralized with ammonia ,

the precipitate is the desired hydrated stannic oxide ,

which does neutralize nitric acid completely . The

tin nitrate solution formed is unstable above ~50C ,

(by itself) but when it is combined with certain other

metal nitrates , at the proper pH , it forms a stable

hydrogel which has a high metals loading and needs

no PVA thickener .

This is the direction I think is most promising of all ,

as it would likely give the same good nitrate derived baked coatings for SnO2 and doped SnO2 , as has been

showing good results in Xenoids experiments for the nitrates of Co and Mn .

The oxidative soak deposition of SnO2 from SnCl2 + NaNO3 also seems to be good bet as the simplest way

of applying an SnO2 layer , if one has the patience to

wait for the hours it takes to slowly deposit . That

method could be the reaction left overnight to slowly

deposit .

[Edited on 28-12-2007 by Rosco Bodine]

|

|

|

chloric1

International Hazard

Posts: 1147

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Yeh I think that was the right patent. Sorry I got my wires crossed yesterday, its easy to get confused with a fever of 38°C.

I have prepared solutions of cobalt and nickel nitrate. I was going to refer to the approximate mass of elemental metal dissolved in a designated

volume of water. Unfortunately, when dissolving my nickel sulfate in water,with haste, to make nickel nitrate I forgot to measure how much I

used. I still have to make some manganese nitrate. Judging from the patents, it

seems probable that it would be OK to bake at 400°C and for a little longer times. I still have to make some manganese nitrate. Judging from the patents, it

seems probable that it would be OK to bake at 400°C and for a little longer times.

Fellow molecular manipulator

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Chicken soup and pseudoephedrine and paracetamol and orange juice for you . Soak in a hot tub until you break a sweat ....sometimes that will help

too . I'm a little under the weather myself . Bears should be hibernating this time of year

If you have good analytical scales , a quadruple beam Ohaus 311 centigram for example is okay ....

You can always take a sample of your unknown solution ,

( analysis of an aliquot compensates for a sore twat  ) )

And then you do your quanitative analysis based on

precipitation of the carbonate for example . In this

case save the analysis sample of carbonate because it reportedly improves the nitrate bakeout to include about 10% of the carbonate in the nitrate

coating mixture , for manganese this is reported to be true anyway . It probably follows for the other nitrates as well , where

the carbonate likely serves to thicken the mixture and/or

buffer and smooth the decomposition on baking .

I have some tangential references which mention tin nitrate related information and I will post them in dann2's

thread regarding antimony and tin nitrate .

http://www.sciencemadness.org/talk/viewthread.php?tid=8347

[Edited on 29-12-2007 by Rosco Bodine]

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

++++ Gertrude is Dead ++++

Long live Hubert...

I am sorry to report that the brave little anode Gertrude (known affectionatly as "Gerty" to some of you) died this afternoon local time.

During her short lifetime of approximately 146 Amp hours, in the often harsh environments of assorted perchlorate cells, Gerty is estimated to have

converted about 280g of NaClO3 to 322g of NaClO4.

Gerty died from the hideous effects of slow passivation followed by massive overvoltage application.

Please do not let this happen to your anodes!

Gerty died alone, while I was having a pleasant hike in the mountains. I had inadvertantly left the voltage limiting set to maximum (~ 30 volts) on my

lab power supply while running in constant current mode (1 amp). I am not sure what the exact "breakdown" voltage for the passivated layer is, but it

obviously less than 30 volts...

I now have a 300 ml perchlorate cell "chocka-block" full of steaming, white, TiO2 gloop!

Moral, never apply more than about 10 volts across a Ti anode in a perchlorate cell!

I have more "bad news" but I am too distraught to report it at the present time...

[Edited on 29-12-2007 by Xenoid]

|

|

|

| Pages:

1

..

9

10

11

12

13

14 |

|