| Pages:

1

..

22

23

24

25

26

..

47 |

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

The puzzle has been solved. The 'solution' was posted here many moons ago. I /we are trying to do the same thing with more OTC materials. It ain't

working for me I guess.

See here for working homemade Ti substrate, DTO + Lead Dioxide anode.

http://www.sciencemadness.org/talk/viewthread.php?tid=1425&a...

from a guy who actually made lots of anodes.

More discussion of anode here:

http://www.sciencemadness.org/talk/viewthread.php?tid=2465&a...

He use Butter of Tin and Butter of Antimony + water + Buthanol.

Dann2

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

If the SnCl4 plus SbCl3 was so straightforward as to be the simple solution , then you wouldn't be having huge problems with it , would you ?

Alembic wasn't very forthcoming with the particulars concerning the intermediate layer ...was he ?

The problem of volatility has been mentioned with regards to the chlorides precursor mixture .

There is a gap in the temperature range where there is an indeterminate variable loss of the chlorides precursor mixture

due to volatility .....before the decomposition to the non-volatile oxides takes place ....at a higher temperature .

This alone is a problem I have pointed out before , which

makes the rate of heating affect the composition of the

residue of oxides , as well as how much of that residue is

even there .

Attached is a patent which uses a vapor deposition method

for metal oxide applied to a ceramic substrate to produce

resistors as an electronic component . The mixed chlorides

precursor is used , not as a liquid applied to a substrate and baked .....but as an aerosol vapor contacted with the substrate already raised to the

much higher pyrolysis temperature where the vapors of the mixed chlorides on contacting the much hotter surface , then deposit the desired

oxides as a decomposition product . What makes this vapor deposition process work is precisely what presents a problem

when the mixed chlorides precursor is applied to a cool surface and then gradually heated ....most of it simply evaporates and leaves on the wind ,

literally gone with the wind .....get it ?

[Edited on 31-7-2007 by Rosco Bodine]

Attachment: US3632429 Sb2O3 SnO2 METAL_OXIDE_FILM_Resistors.pdf (196kB)

This file has been downloaded 860 times

|

|

|

Twospoons

International Hazard

Posts: 1327

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

@Hashashan

Here's the controller I built for a hotplate:

http://www.sciencemadness.org/talk/viewthread.php?tid=4896&page=1#pid55520

Works well, holds within a degree or so, and is very simple.

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Why mixed valence oxide precursors may be useful

Stable colloidal dispersions of mixed antimony and tin oxides

are known , where a colloidal dispersion of antimony oxide is *intimately* mixed by *coprecipitation* with a colloidal dispersion of tin oxide , so

that doping is already accomplished at a relatively low temperature for

a dispersion that is a transparent emulsion ....a sol .

Antimony doped tin oxide nano *crystals*of X-ray diffraction

identified character showing only the tin oxide crystal structure , fully enclosing and masking the antimony within the tin oxide crystal structure

are formed from such mixed colloidal dispersions , even at temperatures as low as 200C

in water dispersions heated for 6 hours in an autoclave .....

where the reaction goes entirely to completion . The nature

of the material is a solid solution of antimony entirely caged within the tin oxide crystal matrix . See US4775412 . Compare the coprecipitation of

the Sn and Sb which is performed and *required* in the process with the similar process and material produced by US6777477 . These materials are

probably identical as precursors .....or close enough , and the method of the later patent is simpler .

As a side note of possible interest .....

For colloidal sols of antimony oxide alone see US5008036 .

This patent also references other patent methods for

antimony ethyl glycolate .

For our purposes of producing an amorphous film structure

as opposed to a layer of solid solution nano crystals ...it appears that a variation on the mixed colloidal precursors could be useful , involving the

mixed valency precursors which have a long chain polymeric form and dehydrate intact in that form , rather than precipitating as solid solution nano

crystals . A desirable physical property of such a dispersed polymer is that it has profound effect as a wetting agent and

also has a strong electrostatic attraction to a surface to which it is applied , attaching itself as a persistent coating .

This is reported specifically for SiO2 , but the similar property

likely also applies to TiO2 . The effect is so pronounced that

even teflon is readily wetted by the inorganic polymer and the effect of wetability is persistent , for this material which

remains as a permanent surface layer adhering to the teflon .

Since the dispersion distribution of particles would be so complete already in the "doped colloid" , which would dehydrate as the polymer rather than

a solid solution crystalline form .....during drying and baking , and the electrostatic property is so favorable for adhesion to a substrate , this

would seem to be an ideal candidate for an initial coating .

BTW , this polymer is very possibly involved in the oxidative soak method for deposition of SnO2 . In that deposition method a +II valency Sn(OH)O?

is being gradually oxidized to

a less soluble +IV SnO2 which is precipitated ....but it would seem that the mixed valency polymer would necessarily be present in that reaction

system . And this may be what accounts for the reported strong adhesion of the deposited

films of SnO2 gotten by the oxidative soak method .

[Edited on 1-8-2007 by Rosco Bodine]

Attachment: US3890429 STANNIC_OXIDE_POLYMER_Film Wetting Agent.pdf (399kB)

This file has been downloaded 1132 times

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

more specifics concerning oxidation of titanium

From a couple of pages earlier in this thread ....

| Quote: | Originally posted by dann2

From www.azom.com

____________________________________________

Oxide Film Growth

The oxide film formed on titanium at room temperature immediately after a clean surface is exposed to air is 12-16 Angstroms thick. After 70 days it

is about 50 Angstroms. It continues to grow slowly reaching a thickness of 80-90 Angstroms in 545 days and 250 Angstroms in four years.

The film growth is accelerated under strongly oxidizing conditions, such as heating in air, anodic polarization in an electrolyte or exposure to

oxidizing agents such as HNO3, CrO3 etc. The composition of this film varies from TiO2 at the surface to Ti2O3, to TiO at the metal interface.

Oxidizing conditions promote the formation of TiO2 so that in such environments the film is primarily TiO2. This film is transparent in its normal

thin configuration and not detectable by visual means.

A study of the corrosion resistance of titanium is basically a study of the properties of the oxide film. The oxide film on titanium is very stable

and is only attacked by a few substances, most notably, hydrofluoric acid. Titanium is capable of healing this film almost instantly in any

environment where a trace of moisture or oxygen is present because of its strong affinity for oxygen. Anhydrous conditions in the absence of a source

of oxygen should be avoided since the protective film may not be regenerated if damaged.

__________________________________________

Dann2 |

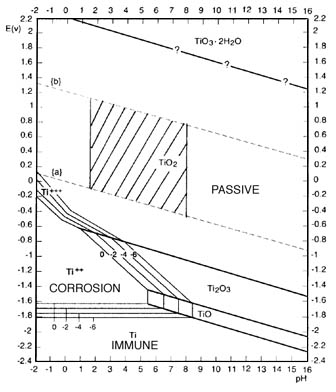

To provide a more detailed look at the pH and electrical parameters which define the reactivity of titanium , these Pourbaix Diagrams are helpful .

This data is useful in predicting what conditions may be helpful not only in plating schemes for titanium , but also in preparation of and coating

and doping schemes for titanium .

The first diagram is generalized and does not account for higher concentrations of dissolved hydrogen , for which titanium exhibits a very strong

adsorption . The second diagram accounts for and shows the effects of the hydrogen .

These diagrams are important so I have saved them locally on the forum server .

Pourbaix diagrams for titanium below were found here

http://www.engr.sjsu.edu/WofMatE/projects/srproject/srproj5....

There are cathodic etching / hydriding schemes which are applicable to plating and also preparation for other coatings for titanium and other metals .

It is possible to do this in a plating bath by first applying a low cathodic voltage to etch and hydride the metal , and then increasing the voltage

to quickly deposit the metal plating so that a good metal to metal interface is produced .

Patents of possible interest concerning this technique are

US5368719 , US5456819 , US2801213 , US4153742 .

I posted this in response to electroplating of iron on titanium

in another thread , but this is also highly relevant here .

[Edited on 9-8-2007 by Rosco Bodine]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Oxalic acid related

There is a patent US3650861 which directly relates to the usefulness of oxalic acid for etching titanium in a controlled way which improves the

adhesion of coatings or platings as compared with other methods .

Also it reportedly is possible to use the mixed oxalates of tin and antimony as non-volatile precursors for baked ATO coatings of high quality on a

titanium substrate , by a simple

dip , dry , and bake method . See US5431798 attached .

Eclectic has mentioned the possible usefulness of an initial

plating of metallic tin directly on the etched metallic titanium substrate , and this is described in the attached patent .

However ...there may be easier or better ways of obtaining

such an initial plating , as the oxalate of tin will itself plate

out tin at an appropriate pH , if the substrate is made cathodic . There are patents which relate specifically to plating of tin from tin oxalate

electrolytes .....and I will have to dig them up to see if there is an example for the conditions for titanium . It may be possible to perform the

titanium etching , tin strike plating , and dip coating for baking ATO , all in one pot using an oxalate / oxalic acid system  . Anyway , for an example of the plating of tin . Anyway , for an example of the plating of tin

from an oxalate bath .....there is a brief description of this

tin plating in a rectifier patent US2368749 , see last page .

Also a variant of these mixed oxalates reportedly produces transparent optical quality coatings . No examples are given for titanium substrates in

these further patents , but the chemistry is described in some detail and the conductivity

of various levels of antimony doping in the finished oxides is charted .....the ~5% figure for antimony oxide agrees nicely with most other sources

which report an antimony percentage range from a minimum of 2% to a maximum of 8% , IIRC . See US4873352 and US4924017 .

Edit :

I just found a later version of the same patent attached below , apparently a parallel application , same inventors , same company , same subject

material ... US5683567 .

[Edited on 17-8-2007 by Rosco Bodine]

Attachment: US5431798 Oxalate Precursors for ATO coated Ti substrate anodes.pdf (130kB)

This file has been downloaded 931 times

|

|

|

hashashan

Hazard to Others

Posts: 255

Registered: 10-10-2006

Member Is Offline

Mood: No Mood

|

|

Say guys, I think i will be able to lay my hands on a nice pice of Ta + Nb foil (surprizingly it will be easier to get then Ti ) Do you think that a

protective DTO layer should be applied on this substrate also? or the Ta wont get oxidized form the PbO2 layer?

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

Absolutely, if you can get it to work. Ta oxide is even better at insulating than TiO2. I don't think it's going to work without some fluoride in

the mix.

|

|

|

hashashan

Hazard to Others

Posts: 255

Registered: 10-10-2006

Member Is Offline

Mood: No Mood

|

|

Oh never mind, somone outbidded me on ebay. I guess ill find some Ti there.

maybe somone here care to sell some Ti?

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Tin Oxalate, where/how to obtain?????

Hello Folks,

Been doing some Patent digging Rosco eh?

The Pat. using the Tin Oxalate is good since it uses a new Tin compound for me/us in the examples, ie. Tin Oxalate.

The obvious question that I am going to ask is, where/how can one get Tin Oxalate?

Tin metal + Oxalic acid is my wild assed guess but quite frankly I don't have a clue.

I am looking at a piece of Ti, on the bench, that I coated with DTO about 4/5 weeks ago. The coating seems to be getting more and more shiney as the

days go by. (The part of the coating at anode top end not etched away when I 'tested' it some weeks ago). I will try putting it into a Chloride

solution as an anode and see what happens. This piece of DTO coated Ti has been tested before in a Chloride electrolyte and it lasted some minutes

when it had sat on the bence for about 2 weeks after it was coated. (Simiarly coated Ti had only lasted about one minute when tested just after

coating).

Perhaps the coating gets better when aged for a few weeks?? ...................Like Whiskey.

We shall see.

Dann2

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by dann2

Hello Folks,

Been doing some Patent digging Rosco eh? |

Yeah you know me ...I occasionally look at a patent or two

trying to find anything interesting

| Quote: |

The Pat. using the Tin Oxalate is good since it uses a new Tin compound for me/us in the examples, ie. Tin Oxalate.

The obvious question that I am going to ask is, where/how can one get Tin Oxalate?

Tin metal + Oxalic acid is my wild assed guess but quite frankly I don't have a clue. |

I looked briefly for a preparation but didn't find anything other than the oxalates have a low solubility in plain water .

I thought probably either direct reaction with the metal

and a hot oxalic acid solution perhaps with added hydrogen peroxide . Boiling a solution of the chlorides with oxalic acid

may also possibly do it , with the HCl byproduct boiling away .

Or perhaps make ammonium stannate and then make the oxalate from that , although the ammonium stannate itself is probably a better precursor to use

directly .

I still think that mixed valency polymer of the approximate oxychlorides composition has the most promise , or an oxidative soak method for getting

the first layer ....but anyway there sure are a few promising alternatives to

the mixed chlorides which are presenting complications .

I have an idea for shortcutting the process if the anode substrate could be a solid titanium rod . Get a rectangular form cast iron burner from an

old radiant space heater , and

chuck the solid rod in a slow speed rotisserie drive like a

zeromax stirmotor or light duty conveyor motor , and do

the baking over an open flame with the part rotating .

You could spray coat your precursor liquids directly onto

the hot part , in several passes as a more or less continuous

process until you get the desired thickness ......instead of doing several separate manipulations . One of those Preval

sprayers like hobbyists use could do the job , or an airbrush

if you have one .

[Edited on 20-8-2007 by Rosco Bodine]

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

Done some Googling [tin oxalate] and came up with this

http://64.233.183.104/search?q=cache:2v4fAkdugnwJ:www.ias.ac.in/matersci/bmsdec2004/491.pdf+tin+oxalate&hl=en&ct=clnk&cd=5&gl=ie

You may need to cut and paste this link.

In document it describes synthesis of Tin Oxalate:

_______________________________________

2.2 Preparation of tin oxalate precursor

This precursor was prepared by dissolving equimolar quan-tities of tin chloride and oxalic acid and stirred well. The precipitate of tin oxalate

obtained was filtered through sintered glass crucible and was washed with oxygen-free distilled water till free from chloride ions and oxalic acid,

finally with dry acetone and was then dried under vacuum.

_______________________________________

Which Tin Chloride do you think it is?

Looks dead easy to me if it is Tin(II) Chloride (SnCl2)!

This link states that SnCl4 forms when Tin metal is added to Aqua Reiga:

http://www.neymetals.com/tin.htm

Oxidizing acid,,,, same as HCl then H2O2?????? I guess.

US 5116468 uses Sn/Sb metal + Oxalic acid to obtain DTO in electrolythic set up. May be applicable to us.

Cheers,

Dann2

[Edited on 24-8-2007 by dann2]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

The SnCl2 is probably what they were using and it would be the stannous oxalate precipitated . The patent however is

producing the higher oxidized stannic oxalate by anodic oxidation of the tin metal . You can get the same thing

I think , without the lengthy electrolysis .

Probably the easiest route would be to just make your clear solution of mixed chlorides with HCl + H2O2 ,

or HCl + NH4NO3 (toxic fumes!) and then neutralize with ammonia to a pH of 7 to 8 to precipitate the mixed basic hydroxides , that is the stannic and

antimonic "acids" . The precipitate will probably settle out by gravity and the waste liquid can simply be decanted , and oxalic acid solution added

and the mixture stirred and heated to form a solution of the mixed oxalates . IIRC you will need some small excess acidity of oxalic acid and

possibly also some small amount of ammonium oxalate present for increasing the solubilities of the mixed oxalates well beyond what is their usual low

solubility in plain water .

[Edited on 24-8-2007 by Rosco Bodine]

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

Sn(II) oxalate is poorly soluble, Sn(IV) soluble. H2S bubbled through a solution of Sn(IV) and some Sn(IV) oxalate precipitates antimony sulfide, but

not tin.

(I'm still experimenting with 95/5 solder as a source of tin)

[Edited on 8-24-2007 by Eclectic]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

IIRC there is a window concentration of diluted HNO3 ....maybe 5-35% concentration range where

the metals are dissolved by the boiling acid and the

nitrates formed are then immediately hydrolyzed with

precipitation of the oxides , or basic oxides . There is an evolution of deadly toxic oxides of nitrogen as a byproduct during the process similarly

as when lead or silver or mercury are dissolved in nitric acid .

After producing the oxides , then they could be converted to other materials by further reaction to produce the desired salt ......like the oxalate .

The implications for the electrolysis are also interesting in another way .

The use of electrolysis in regards to the oxalate

could perhaps be used in an exactly opposite arrangement from that patent , to partially reduce

the higher valency materials to a system of the mixed

valency "polymer" , or sol type of liquid system as has been described for the chlorides . The chlorides could probably be treated the same way as

an alternative electrolytic method of production of that mixed valency polymer , instead of stirring the solutions of the higher

valency salts with the powdered metals , or addition of the

lower valency salts , to form the polymer . A gentle , partial reduction in a divided cell where the higher valency

salts are the catholyte should accomplish the same thing

and the polymer of mixed valency materials should result ,

as an intermediate in reduction before the free metals are plated out .

[Edited on 24-8-2007 by Rosco Bodine]

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by dann2

...

In document it describes synthesis of Tin Oxalate:

_______________________________________

2.2 Preparation of tin oxalate precursor

This precursor was prepared by dissolving equimolar quan-tities of tin chloride and oxalic acid and stirred well. The precipitate of tin oxalate

obtained was filtered through sintered glass crucible and was washed with oxygen-free distilled water till free from chloride ions and oxalic acid,

finally with dry acetone and was then dried under vacuum.

_______________________________________

Which Tin Chloride do you think it is?

|

It's Sn(II), note the use of oxygen-free water for washing.

| Quote: |

...

Oxidizing acid,,,, same as HCl then H2O2?????? I guess.

|

Note that H2O2 contains stablisers, which might affect the product and the end use, given that you are working towards semiconductive materials that

often are sensitive to small amounts of other ions.

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

H2O2 stabilizers are usually in PPM and are generally either tin compounds or phosphoric acid. From my experiments with various lead free solders,

I'd say dissolving 1 lb (500g) lead free solder with about 1 quart (liter) 10-12N HCl in a ceramic crock pot @ 90C for 12-24 hours is cheap and easy

route to obtain fairly high purity SnCl2. The intermetallics from the alloying elements don't seem to want to dissolve unless the oxidation state is

raised with H2O2 and additional HCl. Dropwize addition of 1 part 30% H2O2 to 2-3 parts 10-12N HCl (foaming hazard if acid contains Fe) with vigorous

stirring to the COLD (much heat produced) SnCl2 solution will convert it to SnCl4. Excess H2O2 produces a white precipitate.

Concentrated SnCl4 solution WILL dissolve tin and tin intermetallics.

|

|

|

hashashan

Hazard to Others

Posts: 255

Registered: 10-10-2006

Member Is Offline

Mood: No Mood

|

|

Sorry for reviving a dying thread,

Anyone knows any way to make an alpha lead dioxide coating? I don't want to electrolyze lead in H2SO4 because i need this alpha layer to be plated

directly on silver. Also i would prefer not to use lead tartarate because i just don't have tartaric acid and for some reason it is quite expensive.

|

|

|

Antwain

Hazard to Others

Posts: 252

Registered: 21-7-2007

Location: Australia

Member Is Offline

Mood: Supersaturated

|

|

Have you tried looking in the supermarket for tartaric acid? In Australia, we can get food grade tartaric acid for ~$2/100g and I can't see why it

wouldn't be available everywhere. Its usually near the baking supplies or herbs and spices. If your only shortage is tartaric acid then this may help.

|

|

|

hashashan

Hazard to Others

Posts: 255

Registered: 10-10-2006

Member Is Offline

Mood: No Mood

|

|

Never seen it here.

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by hashashan

Sorry for reviving a dying thread,

Anyone knows any way to make an alpha lead dioxide coating? I don't want to electrolyze lead in H2SO4 because i need this alpha layer to be plated

directly on silver. Also i would prefer not to use lead tartarate because i just don't have tartaric acid and for some reason it is quite expensive.

|

Hello,

It would be a pity to let the thread die!

This may help.

http://www.geocities.com/CapeCanaveral/Campus/5361/chlorate/...

Dann2

|

|

|

chloric1

International Hazard

Posts: 1147

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Suppliers of wine making materials carry tartaric acid. If you are adventurous, and I am still considering this, by cream of tartar and neutralize

with the appropiate amount of sodium or potassium carbonate. Then when everything is in a clear solution add a soluble calcium salt to precipitate

calcium tartarate. When this is thoroughly washed and dried, prepar a dilute (10%) sulfuric acid solution with the exact stochiometric amount of

sulfuric acid and heating with constant stirring for about 2 hours. I would heat to boiling or just under. The resulting calcium sulfate should

consist of large enough crystals to be easily filtered. Concenrate said filtrate until crystals start to form then chill. Tartaric acid is VERY

soluble in water so I do not know how hard this is. Also, adding alcohol to the concentrated solution may help.

Fellow molecular manipulator

|

|

|

hashashan

Hazard to Others

Posts: 255

Registered: 10-10-2006

Member Is Offline

Mood: No Mood

|

|

Hi, did some alpha lead plating, weired thing... i only got a thin brown plating, couldnt get the thick black deposition. Anyone tried to plate alpha?

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by hashashan

Hi, did some alpha lead plating, weired thing... i only got a thin brown plating, couldnt get the thick black deposition. Anyone tried to plate alpha?

|

Hello Hashashan,

Never plated Alpha myself. I used to communicate with a guy who did lots of plating from a Lead Acetate bath, (made from vinegar and Lead metal). It

plated OK but anodes were falling apart. The substate was ceramic.

You cannot plate Alpha onto Graphite for some reason or other.

What is your substrate and bath type.

Dann2

|

|

|

quest

Hazard to Self

Posts: 75

Registered: 15-9-2003

Member Is Offline

Mood: No Mood

|

|

I've been searching and found patent 4,064,035, and got an idea of making PbO2 with no substrate.

I thought of using iron as base

| Quote: |

Examples of substances which satisfy these requirements and which are inexpensive include graphite, titanium, iron and stainless

steel.

|

| Quote: |

Where the electrode is desired to be manufactured in a sheet-like form containing no substrate, it can be obtained by first electrodepositing on one

surface of the substrate an .alpha.-PbO.sub.2 layer and then electrodepositing thereon a .beta.-PbO.sub.2 layer by following the procedure described

above, subsequently repeating this cycles of operation to have additional .alpha.-PbO.sub.2 layers and .beta.-PbO.sub.2 layers electrodeposited

alternately until the combined thickness of layer reaches a required value (about 10 mm), and thereafter separating the substrate mechanically by use

of a cutter or, if the substrate happens to be made of iron, chemically dissolving out the substrate from the substrate by use of an

acid

|

I made all the bathes for alpha and beta PbO2 plating and a iron anode\cathode.

And then I found this link:

| Quote: |

Ions that are bad news in a plating tank, according to the literature, are:

Chloride, Cobalt, selenium, arsenic and iron. The only ion that is likely to effect you is iron. If you are using

'crocodile' clamps made of steel to make connections to an anode that is being plated, you must be careful that no corrosion (it is very likely to

form on the damp clamp) falls or gets into tank. Better not to use Iron at all. Not too sure about SS but it has been in a plating

tank and had no corrosion or ill effects reported. Keep Gouging rods out of the tank as them may contain Iron particles.

|

long post for small punch line:

So it is OK to use iron in a PbO2 electrolysis bath?

[Edited on by quest]

|

|

|

| Pages:

1

..

22

23

24

25

26

..

47 |