stoichiometric_steve

National Hazard

Posts: 827

Registered: 14-12-2005

Member Is Offline

Mood: satyric

|

|

DIY fume hood air flow design optimization

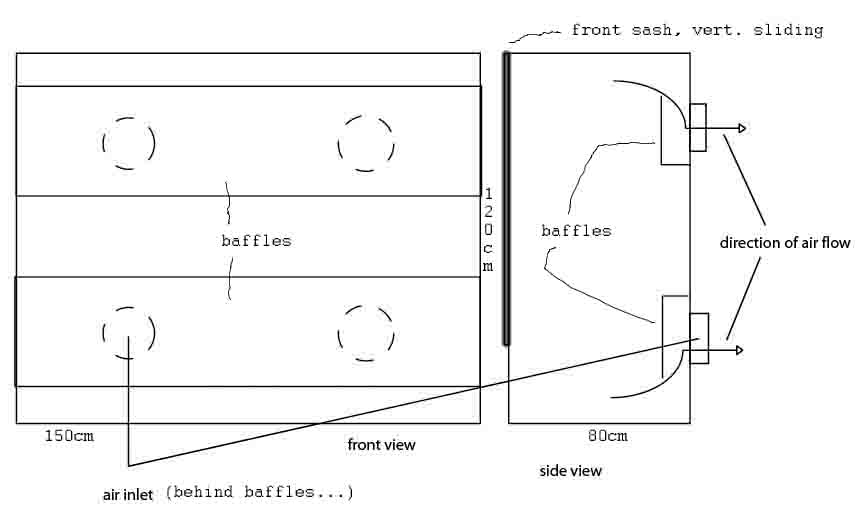

hi, my recently constructed fume hood could use quite some improvement in the air flow.

you're welcome to make suggestions...right now, i'm limited to using 3 axial fans having a flow rate of about 400m³/h, which are aligned to work in

serial, this could be a weak point. maybe arranging the in parallel would make more sense?

please see the attached picture.

[Edited on 7-8-2007 by stoichiometric_steve]

[Edited on 7-8-2007 by stoichiometric_steve]

|

|

|

bio2

Hazard to Others

Posts: 447

Registered: 15-1-2005

Member Is Offline

Mood: No Mood

|

|

Your drawing shows parallel fans not serial.

Equal fans in parallel produce multiples of flow at the same pressure as one fan.

Equal fans in series produce multiples of pressure at the

same flow as one.

So if you arrange the fans in parallel for more flow capacity

hopefully there is adequate pressure to overcome the static

pressure losses.

Minimizing pressure losses by increasing ductwork size and

turning vanes to reduce turbulence will increase flow.

If your fans are axial type then this could be your problem as centrifugal fans usually produce more pressure than axial.

[Edited on by bio2]

|

|

|

volfrahm

Harmless

Posts: 11

Registered: 25-7-2007

Member Is Offline

Mood: Foamy

|

|

This is something I'm looking into at the moment also.

Some things you might want to alter:

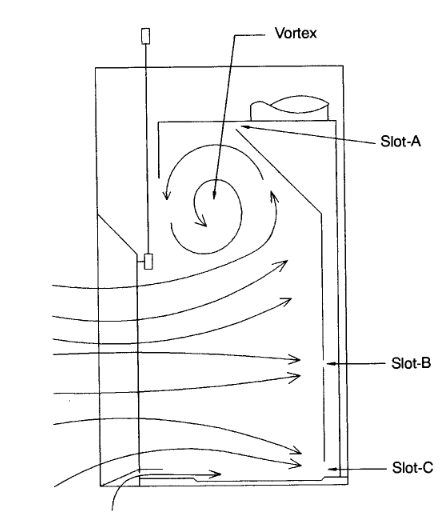

-Place fans in series (in same duct/flow path) at the top of the hood.

-Add back baffle (pretty much an extra wall about 2" from the back; creates airflow along the work surface and at a midpoint of the back wall—a more

efficient/less turbulent version of what the four fans are possibly doing right now)

-Front sash (safety glass, plexiglass, etc) for added safety and better face velocity

-Minor changes to face vertical and horizontal edges to minimize turbulence at the hood opening and minimize contaminant leakage into lab air

Definitely check out the file labfumehoods.djvu (3 excerpt chapters from hood design book).

Here's a side view of a standard hood with airflow arrows (the irregular shape in the upper right is the duct containing the fan):

[Edited on 2007-6-8 by volfrahm]

|

|

|

stoichiometric_steve

National Hazard

Posts: 827

Registered: 14-12-2005

Member Is Offline

Mood: satyric

|

|

| Quote: | Originally posted by bio2

Your drawing shows parallel fans not serial. |

the box in which the fans are arranged in serial is not shown. on the side view, the rectangles on the very right are just the duct pieces to which

the tube work is connected.

this tubing goes to the remote box where the fans are installed.

| Quote: | Originally posted by volfrahm

-Place fans in series (in same duct/flow path) at the top of the hood.

|

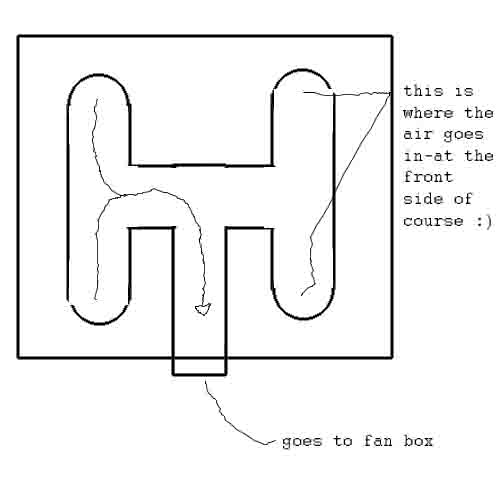

the THREE fans are placed in series in a box standing on the window sill right behind the hood which is connected to the tubework. the tubes connect

the 2 left and 2 right fans to the main tube. see attached picture.

| Quote: | Originally posted by volfrahm

-Add back baffle

|

there is one, see edited picture above.

[Edited on 7-8-2007 by stoichiometric_steve]

|

|

|

volfrahm

Harmless

Posts: 11

Registered: 25-7-2007

Member Is Offline

Mood: Foamy

|

|

haha, might want to include the real design next time you ask for comments

Baffle slots might be too wide—the bottom baffle, for instance, might better extent to about 2" from the floor. And I'm not sure how effective that

top baffle is, since the inlet is 180º to the direction the air will be flowing from the sash opening. Might just be better pointing in the same

direction as the bottom baffle.

That document I mentioned suggests a test with a pie plate of water, with dry ice chunks dropped in. Lets you see how effectively everything gets

sucked out,

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Steve,

I have built a homemade hood, as reported elsewhere in this forum.

I took your estimated flow of 400 m3/hr and your dimensional data (120cm x 150cm) and calculated a face velocity. Maybe this isn't your true opening

dimensions but you didn't give any others to work with. The face velocity I calculated was 12 ft/min. IIRC the old standard was 60 ft/min and the

new is now 100 ft/min. Sorry for the antiquated units but you get the picture. This may be the easy explanation for why your flow does not seem

adequate. (My hood provides ~60 ft/min and works fine.)

It is hard to move enough air unless your fan(s) and exhaust duct have sufficient diameter. I have an 8" diameter (20cm) duct and I believe the

industry standard is 10" (25cm). Even if you don't have much duct length this diameter likely acts as a controlling orifice.

It seems that you are using 3 axial fans in series each about 10cm (?) in diameter. While placing 3 fans in series will indeed give you 3X pressure

drop, I'm guessing that their small diameter just won't provide sufficient flow.

The document submitted by volfrahm looks very good. I think it would be wise to have a baffle arrangement in line with the recommendations of this

document.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

stoichiometric_steve

National Hazard

Posts: 827

Registered: 14-12-2005

Member Is Offline

Mood: satyric

|

|

| Quote: | Originally posted by Magpie

Steve,

I have built a homemade hood, as reported elsewhere in this forum. |

nice, i've seen it. have you got the blueprints for it?

i've only spent like 200 EUR on this hood, it's all made of coated wood though. when the sash is opened by 30cm the calculated face velocity would be

more like 50ft/min according to the value you gave.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

| Quote: |

nice, i've seen it. have you got the blueprints for it?

|

Being old school I only have hand drawings. These are on several pages of ordinary size paper. I could likely photograph them and post, however.

They are for 1/16" aluminum construction but might provide a starting point for other materials.

| Quote: |

when the sash is opened by 30cm the calculated face velocity would be more like 50ft/min according to the value you gave.

|

50 ft/min is not too bad, assuming that this is a good working height for you. Try the pie plate/water/CO2 test and see what kind of flow pattern you

have. If you don't get a decent flow pattern then I would suspect that your baffling is not adequate.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Phosphor-ing

Hazard to Others

Posts: 247

Registered: 31-5-2006

Location: Deep South, USA

Member Is Offline

Mood: Inquisitive

|

|

Please post your drawings Magpie. I have plans to build a homemade hood in the not to distant future. I have a press so shaping aluminium should not

be a problem.

|

|

|

pantone159

National Hazard

Posts: 590

Registered: 27-6-2006

Location: Austin, TX, USA

Member Is Offline

Mood: desperate for shade

|

|

Magpie, please do post your drawings if you can manage it. I am certainly interested, although I don't think I will actually make one in the near

future, but someday...

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I took a photo of one of the 8 pages of pencil drawings that I made for my hood design. Unfortunately it is almost unreadable due to lack of contrast

and small printing.

I'll try again if I get an idea on how to make the photos readable. Sorry.

Here's the photo:

[Edited on by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|