Swinfi2

Hazard to Others

Posts: 131

Registered: 19-2-2018

Location: England

Member Is Offline

Mood: Catalytic

|

|

Electrochemistry and noobery

So I'm trying to make copper sulphate.

Usually one does this with sulphuric acid and copper anode/cathode.

I only have sodium bisulphate so I'm thinking I'll go through copper sulfate to get back to sulphuric acid effectively disproportionating 2NaHSO4

-> -> -> Na2SO4 + H2SO4

First try I had some impurities that were causing the copper to deposit early I assume Cu(1) because it was colourless and turned green when boiled

down. So I recrystalised the bisulphate, set up again (with distilled water not tap) and this happens...

Anyone have any tips or advice?

[Edited on 8-7-2018 by Swinfi2]

[Edited on 8-7-2018 by Swinfi2]

|

|

|

barbs09

Hazard to Others

Posts: 113

Registered: 22-1-2009

Location: Australia

Member Is Offline

Mood: No Mood

|

|

Maybe I don't really understand what you are attempting to do but why not create copper hydroxide (oxide upon heating) by passing a DC current through

copper electrodes in sodium chloride solution. Then reacting the boiled precipitate with your hydrogen sulphate solution to obtain copper sulphate.

plenty on the web and this site on obtaining the heavy oxide (CuO) from the harder to filter hydroxide via boiling.

I have found that this oxide is the easiest copper compound to start with when preparing other copper compounds.

|

|

|

BaFuxa

Hazard to Self

Posts: 61

Registered: 18-9-2017

Location: Mars

Member Is Offline

Mood: Buzzing

|

|

What potential did you apply ?

[Edited on 9-7-2018 by BaFuxa]

Potential counts for nothing until realized.

|

|

|

Swinfi2

Hazard to Others

Posts: 131

Registered: 19-2-2018

Location: England

Member Is Offline

Mood: Catalytic

|

|

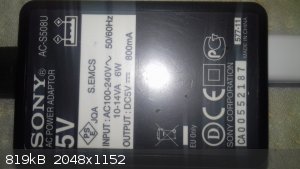

5v from a sony phone charger. I'm thinking it's chloride contamination. After a while the solution went basic and I turned it off. Also my bisulphate

was from a HCl salt cake.

Anyway I took barbs09's advice and boiled it down. Why the hell it foamed so much... (pvc plasticisers?) Anyway now I've got some black definately CuO

to clean up and try with.

Theirs blue on the horizon. CuSO4 blue. Then i can reclaim my "catalytic H2SO4" the same way... hopefully get more yield than boiling it down into SO2

and soot.

So yeah I guess to clarify my goal overall it's to refine my acid sulphate "waste" into fresh acid at the cost of copper contamination. I could

distill but last time I tried that I cracked my still head... probably a fluke but now I don't want to try again.

|

|

|

barbs09

Hazard to Others

Posts: 113

Registered: 22-1-2009

Location: Australia

Member Is Offline

Mood: No Mood

|

|

Glad the boiling got you some black oxide-it tends to clump and settle out much more easily than the hydroxide.

I won't comment on the acid reclamation process but power supply wise, your photo showed it was importantly DC, and could supply 5V at nearly and amp.

So would do the job I imagine. For playing around I use a 5V switch mode PS I bought off ebay that allegedly delivers over 50 amps (cheap as well).

My simple setups use small electrodes and thus limit the current drawn to a manageable 5-10 amps. This current has ability to perform a lot of REDOX.

Have fun

|

|

|

mysteriusbhoice

Hazard to Others

Posts: 477

Registered: 27-1-2016

Member Is Offline

Mood: Became chemistry catboy Vtuber Nyaa

|

|

Your bisulphate may be impure because that green color looks like chloride contamination also if the cell went alkaline then you have sodium sulphate

Na2SO4 and not bisulphate.

In that case the only way i was able to make copper sulfate using sodium sulfate was with a membrane cell.

.

|

|

|