Belowzero

Hazard to Others

Posts: 173

Registered: 6-5-2020

Location: Member Is Offline

Member Is Offline

|

|

Quartz tubes

I feel a bit ashamed of asking this question since a lot has been discussed here on the topic..

I am looking for a quartz tube for medium to high temperature catalyst reactions.

My budget is somewhat limited, whenever possible below 100$.

Now I found a couple of different sources and wide range of quality, one interesting candidate is a replacement tube for UV lamps or ozone generators.

The sellers are not very specific when it comes to purity of the glass and perhaps it won't matter for the purpose?

Another source being IR lamps and alike.

One other thing is how to connect such a tube to borosilicate glassware?

I tried making sense of various pictures from members that operate such devices but I am still not quite sure how to do it.

Hopefully someone can shed some light on this?

Let's say I have a tube oven with a quartz tube and it sticks out for say 20 cm and the oven operates at 800 degrees C.

In what temperature range would the part exposed be?

I can imagine it still being quite hot and rubber would not be an option, perhaps old fashioned cork?

I was absolutely blown away by the prices for quartz with NS adapters and I can imagine this not being ideal anyway since the expansion rate compared

to boro is a sure way to crack it.

Am I missing something here?

Input or general recommendations would be much appreciated!

[Edited on 12-7-2021 by Belowzero]

|

|

|

SWIM

National Hazard

Posts: 970

Registered: 3-9-2017

Member Is Offline

|

|

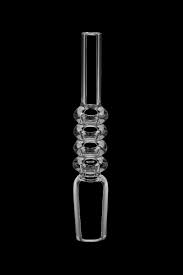

Ive been trying to find a cheap way around this problem myself, and have settled on grinding an internal taper in the quartz tube (about 13/10) so it

can join to a quartz dab straw.

The idea is that this smaller diameter finned tube will cool the gasses quickly, and If necessary I plan on putting a metal box around the fins so I

can use forced air flow or even water cooling.

Whatever it takes to cool those hot gasses fast.

Hopefully by the time the gasses exit the tube they'll be cool enough that I can join that small end to some borosilicate glassware by sticking it in

an appropriate sized hole with some PTFE tape to make it gas tight.

If this fails I may have 2 fused together end to end (small ends) to make a longer quartz condenser.

The item I have is 14/20 jointed, so only suitable for a pretty small quartz tube.

But the idea is to use it to make things on a small scale.

The 'tube furnace' I plan on using it with is also really small.

actually a modified one of these curling iron heaters:

I know this looks like some kind of joke, but the solar electric is the most dangerously overpowered curling iron heater around. It hits well over

700C unmodified, and with a few minor changes it exceeds 900C. My main problem in modifying it is that it destroys insulation and high temperature

sealants.

It is a frighteningly dangerous item for a home hair care appliance. It has no heat control at all (most don't even have on/off switches)and the

electrical contacts are fully exposed and barely insulated at all where they contact the frame.

It's truly amazing what they could sell 100 years ago without getting sued.

Attachment: quartz dab straw collector tip.webp (22kB)

This file has been downloaded 283 times

Attachment: quartz dab straw collector tip.webp (22kB)

This file has been downloaded 248 times

[Edited on 12-7-2021 by SWIM]

EDIT: I intend to control the thing by powering through a Powertrol, and I've purchased a high temperature electronic thermometer with a thin enough

probe that I can slide it in the heating chamber alongside the quartz tube.

EDIT: And no, I have no Idea why they'd make a hair care appliance that achieves such ridiculously high temperatures. I have a hard time imagining how

you'd use this thing without setting your hair on fire.

[Edited on 12-7-2021 by SWIM]

[Edited on 12-7-2021 by SWIM]

|

|

|

Mateo_swe

National Hazard

Posts: 548

Registered: 24-8-2019

Location: Within EU

Member Is Offline

|

|

Links dont work

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

Best choices are UV tubes or heater tubes.

The heater tubes are designed for heat and are fused quartz, standard size is 4"

UV tubes are always very pure silica and slightly larger than fluorescent tubes.

|

|

|

SWIM

National Hazard

Posts: 970

Registered: 3-9-2017

Member Is Offline

|

|

They're working for me, but if you just do an image search for: Quartz dab straw collector, it will come up.

And here it is.

Don't know why I couldn't make it come up yesterday but I tried again and it worked. And these things are really quartz, or at least the ones I bought

are.

Heated them over a gas burner for several minutes and plunged them into ice water with no damage. It did make quite a noise though.

The 14/20 joints are smooth and pretty crappy, but they were improved by grinding them in a 14/20 outer joint lined with 400 grit wet sanding paper,

and then some grinding compound.

[Edited on 13-7-2021 by SWIM]

|

|

|

Belowzero

Hazard to Others

Posts: 173

Registered: 6-5-2020

Location: Member Is Offline

Member Is Offline

|

|

Really interesting SWIM!

Perhaps it is because English is not my native language but I have no clue what a 'dab straw collector' is even after running it through google.

What are the dimensions of such a device? Or are you planning to use those things on the end of a tube?

Using water or air cooling on the exposed parts is quite a nice idea!, perhaps aluminum tubing (as used in refrigerators) can be wrapped around it to

provide cooling.

That heater is one evil device!

Inspired by Magpie (https://www.sciencemadness.org/whisper/viewthread.php?tid=97...) I am planning on building something along those lines.

|

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

What is the outside dimension of your quartz tube?

I joined a quart tube to a borosilicate tube using 3M Kapton (polyimide) adhesive tape. This tape can handle up to 300C in some situations. Please

refer to the picture in this post for details:

https://www.sciencemadness.org/whisper/viewthread.php?tid=84...

The tube inside the furnace is made from quartz, and operates at 500-600C at its hottest point. A few inches outside of the furnace the tube is cool

enough that the tape worked fine with no problems. The spiral condensor that you see in the image (in the ice bath) is made from borosilicate tubing

and is joined to the output of the quartz tube.

This little project involved the gas phase oxidation of ammonia over a Pt catalyst to nitric oxide (and its subsequent oxidation to nitrogen dioxide).

|

|

|

Sulaiman

International Hazard

Posts: 3723

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

I have not checked but I imagine that a 100 year old working electrical device has significant antique value,

may be worth selling?

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

SWIM

National Hazard

Posts: 970

Registered: 3-9-2017

Member Is Offline

|

|

@Belowzero: A "dab straw collector" is actually some sort of drug using equipment.

I think it's for smoking THC extracts, but am not too sure.

***********************************************************

EDIT: So don't buy one if your local law enforcement is difficult about such things.

This doesn't just look like drug paraphernalia; it IS drug paraphernalia, and I doubt the cops would be convinced by your explanation that you're

actually using it for science.

***********************************************************

I found them on Ebay because they used to get listed with the quartz lab equipment.

However they are made of quartz, and are basically small air cooled condensers.

The one pictured above has a 14/20 joint on the large end and it 100 mm long.

I plan to use it on the end of the quartz tube that actually goes through the tube furnace to cool the output gasses from the furnace quickly.

Hopefully this cooling will be sufficient to allow me to fit the other end of the "dab straw collector" into a borosilicate fitting with some PTF

tape.

It's basically just a cheap way to go from very hot quartz tubing to borosilicate tubing without having things crack or get stuck.

Looking over the post I can see it's hard to picture.

I'll start a thread soon showing and explaining the device, and also covering what I do with it.

(or at least try to do with it. This setup may very well not work for any number of reasons, and my hand ground joints may just be too leaky, but I'm

going to give it a try. I'm also unsure about the scale. It may just be too small to be worth using.)

@Sulaiman: Although it is very old (1923 patent date) It isn't all that useful unless you want an exceptionally dangerous curling iron heater.

Some sell on the internet from 20 to 60 USD, but they seldom sell at all because of low demand.

When plugged into a power source the entire appliance (except the stand it sits on, which is probably asbestos or something equally nasty) gets too

hot to touch. There are also several spots on the thing where touching it would give you an electric shock (mains current with no fuse or circuit

breaker).

It does look pretty neat in an antique appliance sort of way though, and I've got to admit that's a large part of why I'm trying to convert it to a

piece of lab equipment.

I suppose I could build something from scratch following directions in various posts on this site that would be simpler to use, cheaper and more

effective, but I like the ancient look of this thing. (the above picture is one of the two models I have to work on. The other is similar.)

Also, The small size means the quartz tubes and fittings for it will be fairly cheap compared to the larger and probably more practical furnaces used

in most labs.

Also, I have to admit that I'm just perverse enough to find the idea of making acetic anhydride with a 100 year old home appliance pretty amusing.

As I said above I will start a thread covering the development of this thing as soon as possible.

I just moved so I'm still sorting through an huge number of boxes of lab equipment and haven't found all of it it yet. And it still needs needs

considerable work.

The photo above is of the same model as mine, but from the internet.

[Edited on 13-7-2021 by SWIM]

|

|

|

Clear_horizons_glass

Harmless

Posts: 42

Registered: 30-9-2019

Location: Pullman, WA

Member Is Offline

Mood: Glass

|

|

Hey there. Scientific glassblower here. I have lots of quartz tubing to make whatever y'all need for tube furnaces. I can weld on long smaller tubes

to the end, I can weld boro to the quartz using graded seals and uranium glass, I can also cut them to boat shapes. Whatever y'all need just message

me. I'm sure I could get ya something for $100 or less.

[Edited on 19-7-2021 by Clear_horizons_glass]

Clear Horizons Laboratory Glassblowing Services

-------------------------------------------------------------

www.clearhorizonsglass.com

Phone and Fax:

(855) LAB-GLAS

(855) 522-4527

Have a glass project you want made? email me at

info@clearhorizonsglass.com

or message us here |

with a U2U |

message |

\/

|

|

|

Clear_horizons_glass

Harmless

Posts: 42

Registered: 30-9-2019

Location: Pullman, WA

Member Is Offline

Mood: Glass

|

|

Would making these really long make a difference? Like 26" as opposed to 18"? I'm also thinking one could just make it 22" and leave more of the joint

shank left to make it 26". 4" on each side seems like enough, right?

Clear Horizons Laboratory Glassblowing Services

-------------------------------------------------------------

www.clearhorizonsglass.com

Phone and Fax:

(855) LAB-GLAS

(855) 522-4527

Have a glass project you want made? email me at

info@clearhorizonsglass.com

or message us here |

with a U2U |

message |

\/

|

|

|

Clear_horizons_glass

Harmless

Posts: 42

Registered: 30-9-2019

Location: Pullman, WA

Member Is Offline

Mood: Glass

|

|

Here is a quote I did for someone else. Thought I would share it in case anyone else is interested.

These numbers are for shipping in the US

Here is the cost for making a 26" quartz 30mm IDx33mm OD tube with inner 24\40 joints on both sides.

Cost of tubing, joints, and shipping to me ... $188

Labor ... $90

Shipping to you ... $75

Total: $353

With 19\22 joints Total: $333

Here is the cost for making (2) 22" quartz 30mm IDx33mm tubes with 2" of smaller tubing in between the furnace tube and the quartz 24/40 inner joints

on each side.

Cost of tubing, joints, and shipping to me ... $264

Labor ... $180

Shipping to you ... $75

Total: $519

Total with 19\22 joints: $458

Here is the cost for making (4) 22" quartz 30mm IDx33mm tubes with "2 of smaller tubing in between the furnace tube and the 24/40 inner quartz joint.

Cost of tubing joints and shipping to me ... $468

Labor ... $360

Shipping to you ... $100

Total: $928

Total with 19\22 joints: $744

Clear Horizons Laboratory Glassblowing Services

-------------------------------------------------------------

www.clearhorizonsglass.com

Phone and Fax:

(855) LAB-GLAS

(855) 522-4527

Have a glass project you want made? email me at

info@clearhorizonsglass.com

or message us here |

with a U2U |

message |

\/

|

|

|