Belowzero

Hazard to Others

Posts: 173

Registered: 6-5-2020

Location: Member Is Offline

Member Is Offline

|

|

Chemically resistent pump

Hello SM,

For a project I need a pump that can handle ~30% nitric acid for long periods of time.

It needs to be able to pump roughly 500ml/minute, higher or a little lower is acceptable.In fact I might need 2.

Continuous operation is also required.

I've been look at some peristaltic pumps which are great for their chemical resistance but the throughput seems to be quite low.

The small Chinese ones come cheap but offer 100ml/minute at best, interesting but not really suitable for this purpose.

Just one example:

https://www.amazon.com/Yanmis-Peristaltic-Laboratory-Bioengi...

The more powerful ones go up in price really quick.

All the other pumps I've looked at so far all contain metal or weak plastics that won't survive nitric acid.

Using vacuum or compressed air is not an option since the system already depends on an air flow.

Price is a consideration.

Any help or creative ideas would be much appreciated!

Also I found some sources about the chemical resistance of PVC vs nitric acid and at 30%(20degrees C.)it should hold, anyone any experience with this?

Or suggestions for plastics that will do better and are affordable?

[Edited on 14-6-2021 by Belowzero]

|

|

|

Dr.Bob

International Hazard

Posts: 2751

Registered: 26-1-2011

Location: USA - NC

Member Is Offline

Mood: No Mood

|

|

Look at FMI pumps, they make a variety of pumps for chemicals, some of which might work. They are certainly solvent resistant, used for many MPLCs

and other chrom systems. Not sure about nitric, but they look pretty inert.

|

|

|

yobbo II

National Hazard

Posts: 764

Registered: 28-3-2016

Member Is Offline

Mood: No Mood

|

|

Quote:

Using vacuum or compressed air is not an option since the system already depends on an air flow.

An 'air lift' pump is ruled out?

https://en.wikipedia.org/wiki/Airlift_pump

There is a thread about them somewhere here.

Very cheap and even DIY.

Yob

|

|

|

Sulaiman

International Hazard

Posts: 3723

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

What pressure/lift/head-height do you require?

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Could your problem be solved by using 5 of the smaller pumps at once?

|

|

|

Belowzero

Hazard to Others

Posts: 173

Registered: 6-5-2020

Location: Member Is Offline

Member Is Offline

|

|

I would have no idea to how to incorporate this into the design.

Perhaps I should have explained what I am actually trying to do:

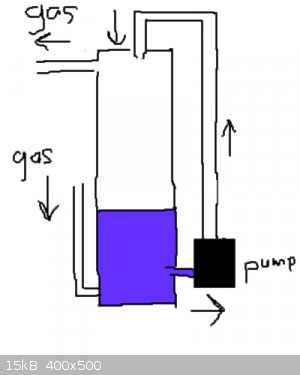

I am trying to build a couple of scrubbing towers as used industrially.

Basically a packed tower where gas is injected at the bottom and liquid sprayed into the top continuously.

Since I already use pressure to move the gas into the tower I can't have a competing air current to move the liquid since it would require quite a lot

more pressure (at least thats my guess)

The liquid sprayed on top would ideally go through a nozzle of sorts the improve the surface area, hence require quite some pressure.

| Quote: |

Could your problem be solved by using 5 of the smaller pumps at once?

|

This could work but would also get quite expensive, perhaps if I can find really cheap peristaltic pumps it might work.

| Quote: |

What pressure/lift/head-height do you require?

|

Only about .5 meters or so, as mentioned above I would prefer to use a nozzle and spray it.

I can imagine this putting some strain on the pump.

I have very little experience thinking about such problems so please forgive my ignorance

[Edited on 15-6-2021 by Belowzero]

|

|

|

Hoffit

Harmless

Posts: 21

Registered: 12-8-2019

Member Is Offline

Mood: Excited

|

|

How about something out of the box like having a checkvalve and a container at the bottom (to drain the liquid into) and then using gas pressure and a

siphoning tube to move liquid to another container at the top? Then drain (if gravity works, not good for spraying though) or do whatever with the

liquid on the top. Perhaps brute force cyclic siphoning every now and then instead of sensing liquid level on the bottom. Just empty it often enough.

(pressure to the top during siphoning can be an issue).

(I've not really thought through that yeat, just to give you another idea out of the box)

I guess after all the hassle with that, you may want to pay for a larger perilstatic pump after all. I think some larger stepper motor driven ones and

similar are available for $100 or below, depending on the flow rate needed.

|

|

|

Sulaiman

International Hazard

Posts: 3723

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

Multiple small pumps for the acid seems do-able and you can build in some redundancy.

You could consider a high pressure (eg 5m = +0.5 bar) pump for the gas and bubble the gas through a static column of nitric acid?

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

BromicAcid

International Hazard

Posts: 3253

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

So long as you can deal with slight pulsations a diaphragm pump would be the way to go. Obviously you can get them in all PFA/PTFE but you can

certainly step down from there to something that is just resistant to nitric. Probably Viton though EPDM is cheap and has a fair rating to <50%

nitric.

[Edited on 6/16/2021 by BromicAcid]

|

|

|