SuperOxide

Hazard to Others

Posts: 486

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

How is medium/large scale sublimation accomplished?

I just got through making ~53g of phthalic anhydride, and overall it was a pretty simple process, but the phthalic acid dehydration step to form

phthalic anhydride was particularly tedious, which was compounded by the fact that I only had a 250mL beaker, so I could only do so much at a time. (I

know I could have just recrystallized it, but sublimation seemed to yield a much cleaner product).

While I was sitting there repeating the same damn step over and over and over and over again, I got to thinking... If one wanted to do this on a

larger scale (hypothetically, of course), how would it be done? Obviously I could just get a bigger beaker which would save a lot of time (and

sanity), but I mean on a larger scale than that even. I think even if you chose to simply keep getting a bigger beaker/vessel for a larger scale

sublimation, since the sublimation occurs on the surfaces of the container, you would quickly start running into the law of diminishing returns

(square-cube law I think).

Most other small/medium scale purification techniques scale up reasonably well (fractional distillation of petroleum, large pressure vessels for

growing crystals, etc), but how would one scale up sublimation? Is there a way to accomplish some continuous sublimation? (maybe the surface that the

crystals adhere to slowly rotates into an area where they get scraped off into a container? etc). Or is sublimation just avoided in favor of other

purification techniques?

Edit: To clarify - my question wasn't about how phthalic anhydride is sublimated on an industrial scale, but rather how sublimation

itself is done on such a scale (for any chemical).

[Edited on 2-1-2021 by SuperOxide]

|

|

|

valeg96

Hazard to Others

Posts: 254

Registered: 6-4-2014

Location: Italy

Member Is Offline

Mood: Moodless

|

|

The answer is very simple... On a large scale, you use other syntheses, such as the oxidation of naphthalene or o-xylene.

|

|

|

SuperOxide

Hazard to Others

Posts: 486

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by valeg96  | | The answer is very simple... On a large scale, you use other syntheses, such as the oxidation of naphthalene or o-xylene. |

My apologies, i was asking if sublimation is ever used on a larger scale at all, not specifically for phthalic anhydride, that was just what made me

think about it.

|

|

|

valeg96

Hazard to Others

Posts: 254

Registered: 6-4-2014

Location: Italy

Member Is Offline

Mood: Moodless

|

|

Oh. I missed the question then. Sublimation was widely used for the production of some inorganic chemicals, but I fear it's not the case anymore.

Sublimation was famously used to produce and purify As2O3; they basically filled an oven with As minerals or impure As2O3, lit a fire under the hearth

of the oven and the fumes of sublimed oxide were conveyed into an upper chamber, cooled, and condensed on the walls. When the oven was shut off, then,

workers entered the upper chamber and scraped off the glassy pieces of pure As2O3. Nowadays it isn't done that way anymore (... Probably. But with

China's arsenic industry I wouldn't swear by it!) I can't think of any modern commodity chemical that is produced with a sublimation step.

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

Not even iodine?

For amateur, generally any process that requires no reagents is a potential primary method. Industry can readily access large amounts of macabre

solvents and reagents while they can be totally unavailable otc. If a substance can be purified through sublimation, it will likely produce the purest

outcome with highest yield. Recrystallization suffers from variable yield losses, especially if the mother liquor is not reused for continuous

production.

[Edited on 2-1-2021 by Fyndium]

|

|

|

SuperOxide

Hazard to Others

Posts: 486

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by valeg96  | | When the oven was shut off, then, workers entered the upper chamber and scraped off the glassy pieces of pure As2O3. |

That sounds dangerous, lol (due to the As2O3 toxicity, not the oven, obviously).

Ok, that's what I assumed. Out of curiosity I tried looking it up to see if there was any industrial machinery that is/was used for it (maybe even a

continuous process like the fractional distillation columns in oil refineries), and didn't have much luck.

Overall, sublimation seems like a pain in the ass (in my limited experience). So I suppose it makes sense it's avoided on an industrial scale in favor

of processes with better efficiency.

|

|

|

Dr.Bob

International Hazard

Posts: 2732

Registered: 26-1-2011

Location: USA - NC

Member Is Offline

Mood: No Mood

|

|

It is still used occasionally for compounds that work well, which includes iodine, ferrocene, and naphthalaene. But some ionorganics also work well,

like for electronics.

For lab scale, they make sublimation apparati that are quite large and can be water or ice cooled. I have a few various ones, the largest could

likely do 100 grams. I've done a few large scale ones before, but best for things that are hard to purify other ways.

See https://pubs.acs.org/doi/10.1021/ed045p538 and https://www.tcichemicals.com/TH/en//custom-synthesis/sublima... for some examples.

|

|

|

SuperOxide

Hazard to Others

Posts: 486

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Oh neat, thanks for the links! I guess I was wondering how companies like Alfa or Fisher would do it if they needed to. That answers it.

----

Related story: I was running into this problem where a bunch of crystals would form, and I would take it off the hot plate, then the mass of crystals

would fall from the beaker or sides of the flask and melt back into the mass at the bottom. Really pissed me off.

I saw some video where a chemistry professor suggested getting a filter paper a little smaller than the inner diameter of the beaker, and put it on

top of the chemical being sublimated at the bottom. According to the video, the crystals would fall down but you could get them off the filter paper.

Seemed a little odd, but maybe worth looking into...

Well, I tried it, and it was a damn disaster. Apparently my hot plate was hot enough to literally char the filter paper. It turned into a big black

mess at the bottom, and smelled like I set some paper on fire. lol.

Fricken disaster. Oh well, learned my lesson.

|

|

|

valeg96

Hazard to Others

Posts: 254

Registered: 6-4-2014

Location: Italy

Member Is Offline

Mood: Moodless

|

|

I don't know how I didn't think of iodine, naphthalene and ferrocene. Now that I think about it, also camphor may be purified that way; I also can't

find any substantial information on industrial scale sublimation reactors.

Even regarding iodine, what I could tell you is definitely obsolete. Sublimation was carried out in ceramic retorts that led the condensate in chilled

vats or cylinders, which were then scraped clean.

I've found this company https://www.iochem.net/ but the information they provide is minimal; it seems like they play mostly on iodine solution chemistry, precipitation

and prilling, and barely mention how they sublime their iodine. I somehow suspect the procedure is basically unchanged, of course with safety and

material improvement, but it can't be that different.

About non-commodity chemicals like those sold by Alfa et al., they use the equipment Dr. Bob mentioned, on the kg scale.

[Edited on 2-1-2021 by valeg96]

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

You could use ordinary flask and a condenser column to sublime the stuff under vacuum. Ground joint glass tube works as well, and it can be placed

horizontally so the crystals won't fall back to the reactor.

Placing a simple coldfinger in the flask also works for smaller amounts. The outlet should be larger though, either with reducer joint or using

reactor vessel with flange.

The filter paper should be supported with something. If it lays by its own rigidity or over the sublimee, it will eventually sink and wetten - or

char.

|

|

|

SuperOxide

Hazard to Others

Posts: 486

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

That's what I thought, but I don't remember that being mentioned in the video. Perhaps I'll give it another go and support it with something.

Char... in my case, lol.

Take a look-see below. I may try to get the phthalic anhydride out of it anyways. It still seems to sublimate out ok, just smells really bad, lol.

Then there's the 53.64g of the phthalic anhydride I made (sublimated then melted and pulverized so it wouldn't be so darn fluffy), just to make the

charred phthalic anhydride look even worse :-D

P.S. I think what I may do next time is put a small crystallization dish containing the crude substance at the bottom of a beaker

with maybe twice the diameter. That way when the crystals attach to the sides, if they detach and fall, they should mostly fall to the outside of the

crystallization dish, thus remaining pure. I don't usually care that they're nice crystals so long as they're pure - I've grown to hate the puffy

cotton like crystals of purified phthalic anhydride, lol.

[Edited on 3-1-2021 by SuperOxide]

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

I think the commercial production of ammonium chloride (from ammonia derived from coal gas) involved sublimation to purify it and, as far as I recall

they used cast iron retorts.

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

The way to go is to just melt the phthalic acid (it first dissolves in its water, then boils and crystallize again) while not burning it. When done

carefully it stays perfectly white. I did 50 grams in a half liter beaker with a round bottom on top.

You shouldn't fill the round bottom with water, as this will condens the water back in the now over 100 degrees phthalic acid/anhydride, making it

boil and shoot acid out of the beaker.

|

|

|

SuperOxide

Hazard to Others

Posts: 486

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by Tsjerk  | | The way to go is to just melt the phthalic acid (it first dissolves in its water, then boils and crystallize again) while not burning it. When done

carefully it stays perfectly white. I did 50 grams in a half liter beaker with a round bottom on top. |

I haven't had any problems burning the phthalic acid/anhydride at all, the charring was from me trying to make the process easier by adding a round

filter paper on top of the crude phthalic anhydride, and the paper itself charred.

However, if I do this again, I think I'll try the trick I mentioned above in my previous post to keep the crude phthalic anhydride separate from the

purified crystals that fall down from the sides.

Quote: Originally posted by Tsjerk  | | You shouldn't fill the round bottom with water, as this will condens the water back in the now over 100 degrees phthalic acid/anhydride, making it

boil and shoot acid out of the beaker. |

I never filled it with water at all, what makes you think that?

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

I didn't think you added water, but in sublimations in general it is often done, in this case it is not necessary.

|

|

|

SuperOxide

Hazard to Others

Posts: 486

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

Quote: Originally posted by Tsjerk  | | I didn't think you added water, but in sublimations in general it is often done, in this case it is not necessary. |

Ahh ok. Yeah I know that when phthalic acid decomposes into the anhydride form, it releases some H2O as a by-product. Because of that I would usually

heat it up slowly to just over 180 °C, as that's when the anhydride is formed. Then once I see no more water condensing anywhere, I crank the hot

plate up to around 295 °C to get the anhydride to sublimate out.

|

|

|

zed

International Hazard

Posts: 2283

Registered: 6-9-2008

Location: Great State of Jefferson, City of Portland

Member Is Offline

Mood: Semi-repentant Sith Lord

|

|

Short path vacuum distillation?

https://patents.google.com/patent/US3725211A/en

|

|

|

SuperOxide

Hazard to Others

Posts: 486

Registered: 24-7-2019

Location: Devils Anus

Member Is Offline

|

|

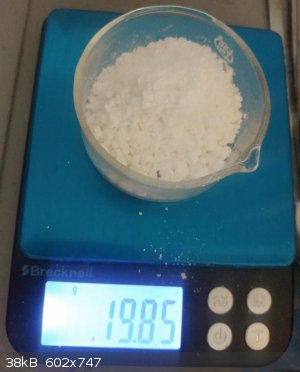

Hey, very neat, thanks! I do have like ~19.85g of [slightly wet] crude phthalic acid (which I got from 20 DEHP gloves, surprisingly high yield) that I

haven't processed yet.

This is the last bit I plan on converting to the pure anhydride form, and I don't have a short path distillation apparatus, but I can just use a

distillation head with no condenser. If I do, perhaps I'll share some updates (especially if it's a disaster.. lol).

|

|

|

SWIM

National Hazard

Posts: 970

Registered: 3-9-2017

Member Is Offline

|

|

Kontes makes some fairly large sublimators

https://www.ebay.com/itm/Aparato-De-Sublimacion-grandes-Kont...

And I've seen even larger ones based on polymer reaction kettles with special cold finger inserts that are shaped like Erlenmeyer flasks.

https://pr.vwr.com/store/product/12117456/vacuum-sublimation...

These both show up on ebay now and then, and can often be bought pretty cheap as long as some pirate like me hasn't bought them up to re-sell at a

profit.

Yeah, $350 was a little steep, but I did throw in that big old clamp, so I don't feel too bad about it.

You'd be amazed what some folks charge for those 100 mm clamps.

EDIT: Hey! somebody is selling one without the outer shell for $100.

https://www.ebay.com/itm/Kontes-Flat-Bottom-100ml-Sublimatio...

I bet you could fit that right into a 2000 ml ACE reaction kettle and it'd work pretty well.

NOTE: the ad is mis-labeled. It is a 100 mm sublimator, not 100 ml.

[Edited on 15-1-2021 by SWIM]

[Edited on 15-1-2021 by SWIM]

Anybody actually wants to try this, I'm willing to supply you with a round bottom reaction vessel and/or 100 mm clamp dirt cheap. say $75 plus postage

for the 2 items. the vessel has a flat flange, but I'm pretty sure these will mate to a grooved flange like the sublimator lid and hold vacuum well if

you use an O-ring and grease.

It'd be worth it to see this thing made usable again instead of ending up decorating some steampunk's apartment.

[Edited on 15-1-2021 by SWIM]

[Edited on 16-1-2021 by SWIM]

|

|

|

BromicAcid

International Hazard

Posts: 3245

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

Unfortunately a lot of large-scale sublimation is basically an artisinal craft, dozens of sublimators running round the clock, sometimes for days at a

time each kicking out 1-4 kg at a shot.

|

|

|