Housane

Hazard to Others

Posts: 127

Registered: 3-9-2018

Location: Worcester, England

Member Is Offline

Mood: Let’s make

|

|

Hydrothermal reactor

Hi all,

I am looking to start experimenting with hydrothermal reactions and was wondering what pipe I should use to create my reactor and how much pressure it

should be able to withstand?

Regards

Housane

Green QD's so far

Feel free to correct grammar or incorect knknowledge. We are all learning.

|

|

|

Ubya

International Hazard

Posts: 1247

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

i would say, if you are not going to invest in a real hydrothermal pressure vessel, go with a nipple and caps, nipples are thicker than normal pipe,

and are pretty cheap, the only drawback is that they are small.

what pressure they can withstand? it's pretty thick metal, at least 3mm in the thinner areas (it's the threaded part, so the cap is adding another 3mm

at least).

just be safe to begin with, i tried this experiment on my hotplate, set for maximum 180°C, staying far away from it while hot, and with a thick wood

cage around it (not in the picture) to hopefully catch flying pieces in case of explosion (sandbags are better, but heavier).

my pipe leaked anyway, so the pressure never got too high

[Edited on 7-6-2020 by Ubya]

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

Housane

Hazard to Others

Posts: 127

Registered: 3-9-2018

Location: Worcester, England

Member Is Offline

Mood: Let’s make

|

|

Thanks Ubya, i'll look into that method

Green QD's so far

Feel free to correct grammar or incorect knknowledge. We are all learning.

|

|

|

Refinery

Hazard to Others

Posts: 371

Registered: 17-2-2014

Member Is Offline

Mood: Still

|

|

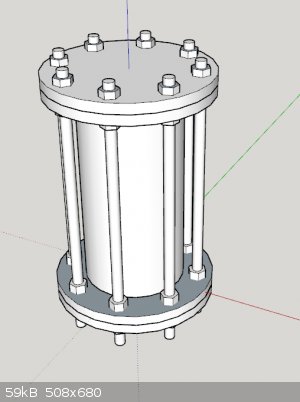

If you have access to TIG welder it will solve all your problems. Get a thick walled SS tube, weld flanges to both ends and put threaded rods through

it. You can pressure proof the vessel with hydraulic pressure gauge.

Properly made containers can easily withstand hundreds of bars, more robust and smaller ones even thousands. We had a tabletop test gauge about 5"x10"

in size with a hand crank and it had a gauge up to 2000bar. Leaking is usually more of an issue.

|

|

|

wg48temp9

National Hazard

Posts: 783

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

Stay safe: Any pressure vessel made from random and unknown pieces SS by an armature welder should only be pressurised in a hole in the ground with a

paving slab covering it. That should probably include any experiments with any high pressure bottles.

In the UK Soda Stream bottles can sometimes be found in charity shops and purchased cheaply. OK the charity shops may be closed at the moment so you

could try a recycling sites like one of the Freegle sites.

They are tested to 30bar (from memory) and have a burst disk set to about 100bar (thats the item sticking out of the side of the brass valve). The

brass valve can be removed for modification with a big spanner and at least 3ft of pipe for leverage.

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|

Refinery

Hazard to Others

Posts: 371

Registered: 17-2-2014

Member Is Offline

Mood: Still

|

|

Absolute terms, relative perception. I have a friend who is a "know-it-all-guy" but actually goes wrong even on some basic stuff. These are the people

who blow things up by just putting some pressure generating substances in a closed vessel and wait for things to happen. Materials can withstand

surprising stresses, but when they fail, the more damage will occur. A vessel bursting at 500bar is not far from an actual fragmentation device.

I'm not to say anything, but I've worked with pressure vessels and welding and could confidently say that if I were to make a vessel to withstand

static 100bar pressure, it would be no trouble.

When you proof things, you fill them with water and add pressure with gauge-meter. In this manner, if the vessel fails, it has only few cubic cm of

gas to expand. If it withstands 300bars, you can confidently use it at 100bar. Other factors, aka material and gasket compatibility, temperature etc.

must be taken into consideration.

But for example, a reaction that is done with ethanol as solvent at 100C, will generate pressure inside the vessel. One manages the pressure by just

immersing it in boiling water.

|

|

|

Ubya

International Hazard

Posts: 1247

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

Quote: Originally posted by wg48temp9  | Stay safe: Any pressure vessel made from random and unknown pieces SS by an armature welder should only be pressurised in a hole in the ground with a

paving slab covering it. That should probably include any experiments with any high pressure bottles.

In the UK Soda Stream bottles can sometimes be found in charity shops and purchased cheaply. OK the charity shops may be closed at the moment so you

could try a recycling sites like one of the Freegle sites.

They are tested to 30bar (from memory) and have a burst disk set to about 100bar (thats the item sticking out of the side of the brass valve). The

brass valve can be removed for modification with a big spanner and at least 3ft of pipe for leverage. |

those are pretty huge for a hydrothermal experiment

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

Heptylene

Hazard to Others

Posts: 319

Registered: 22-10-2016

Member Is Offline

Mood: No Mood

|

|

You can go with regular plumbing supplies. The galavanized steel ones I've seen are rated for use to 30 bars. There are probably heavy duty plumbing

parts that can withstand more. Study the possible interactions between the contents and the vessel material at high temperatures and pressures. It can

differ from room temperature at 1 atmosphere.

Plan for the worst case scenario: rupture of the vessel. You'll need a blast shield, etc.

|

|

|

Texium

|

Thread Moved

29-11-2023 at 13:29 |