Volitox Ignis

Hazard to Self

Posts: 53

Registered: 28-1-2016

Member Is Offline

Mood: No Mood

|

|

Advice on Turbine and Pump Designs

I am currently working on designing an oscillating water column as part of a project. In summary:

| Quote: |

OWC are devices with a semi-submerged chamber or hollow open to the sea below, keeping a trapped air pocket above a water column. Waves force the

column to act like a piston, moving up and down, forcing the air out of the chamber and back into it. This continuous movement force a bidirectional

stream of high-velocity air, which is channelled through a Power-Take-Off (PTO). The PTO system converts the airflow into energy.

|

https://en.wikipedia.org/wiki/Oscillating_water_column

In my case, the PTO system is a turbine, the rotation of which will power a water pump.The pump rotor and the turbine would be on the same axis and

connected by a rod. In short, the rotation of the turbine would directly power the pump.

I have found a couple potential turbine and pump designs for this, but I am having a hard time deciding which of them would work best for such a

system.

Turbine Candidates:

-Wells Turbine

-Bidirectional Impulse Turbine

I'm looking for the most efficient turbine design, but the only thing I've found was that a Wells turbine can have an efficiency of between 40% and

70%

I would also like some advice on which pump would be best suited for this system. Although I have researched a few pump types, I haven't found much

information on how efficient various designs can be.

A few important things to note:

-The pump must be capable of sustaining a pressure of at least 800 psi, but 1000 or more would be preferable.

-This is a rather small-scale design and there are size constraints, so if some pump or turbine designs don't scale down well, that would be important

to know.

-Knowing the efficiencies of the optimal turbine and pump types would also be nice.

[Edited on 27-8-2019 by Volitox Ignis]

|

|

|

Corrosive Joeseph

National Hazard

Posts: 915

Registered: 17-5-2015

Location: The Other Place

Member Is Offline

Mood: Cyclic

|

|

Gas Turbine Design, Components and System Design Integration - Meinhard T. Schobeiri

https://b-ok.cc/book/2931196/024891

The Design of High-Efficiency Turbomachinery and Gas Turbines David Gordon Wilson and Theodosios Korakianitis

https://b-ok.cc/book/3413589/60dd10

/CJ

Being well adjusted to a sick society is no measure of one's mental health

|

|

|

Sulaiman

International Hazard

Posts: 3692

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

I am not a mechanical engineer, but here are a few thoughts and questions ;

Q1) how high above sea level do you need to pump water ?

(from your requirement of 800 to 1000 psi I guess 50 to 60 metres)

Q2) would you be pumping sea water or fresh water ?

Q3) what scale are you envisioning ? e.g. litres or cubic metres per day

T1) as you do not need to power a rotating generator, you could just use the vertical linear motion,

e.g. a large diameter membrane (or piston) driven by the waves (via the air pressure)

could be mechanically coupled to a much smaller diameter membrane (or piston) that pumps your high pressure water ?

The overall efficiency would be very good I expect.

T2) you could sacrifice a little efficiency by having a small air leak to the large chamber,

this would ensure that the water level / air volume maintains an average level.

T3) if you use a piston for the large chamber then some sort of restoring force will be required to operate at an average level,

e.g. a spring.

T4) the air leak could take the form of a piston slightly smaller than its cylinder,

this would greatly increase simplicity of construction,

if you opt for a piston rather than a membrane.

T5) the air leak could take the form of an imperfect membrane,

saving on the cost of a perfect membrane.

T6) I guess that this scheme would need much less precision engineering for the bearings,

a reciprocating shaft that does not need to be air or water tight vs. the rotary bearings of turbine and pump.

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Volitox Ignis

Hazard to Self

Posts: 53

Registered: 28-1-2016

Member Is Offline

Mood: No Mood

|

|

Q1) I don't need to pump the water that high. Maybe one or two meters above sea level at most. What I do need my design to do,however, is pass the

water through a reverse osmosis membrane, so that's why I need such pressures.

Q2)Seawater

Q3) I'm hoping to get at least several liters per day

I like your idea, could you please provide something to help me visualize it,though? A simple sketch in MS paint would be fine.

|

|

|

Sulaiman

International Hazard

Posts: 3692

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

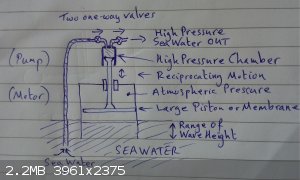

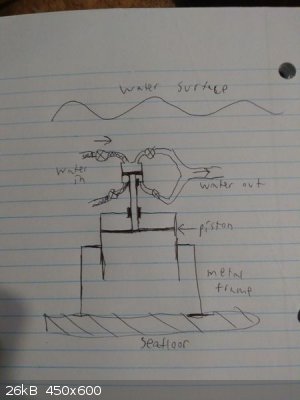

something like this ;

The smaller high pressure cylinder (pump) has to be rigidly connected to the large low pressure cylinder (motor)

the entire assembly needs to be anchored, e.g. to the seabed, or a cliff face, sea wall, or jetty etc.

allowance for changes in tidal water level is required ... I have ideas

as water is negligibly compressible the one-way valves do not need to be on the cylinder head,

but may be if required.

Each of the two valves could be as simple as a plumbing 'check valve' or just flaps over orifices as found in membrane pumps.

The height / stroke length of the pump cylinder needs to be greater than the stroke length of the motor,

which will be less than the wave height due to the compressibility of air, not shown correctly in my diagram.

_________________________________________________________

You could dispense with the large cylinder completely by using a float instead of a membrane or piston,

but short-period waves will put more stress on the system.

You could also have a float on a pivoted beam,

and have the pivoted beam operate the pump,

the choice of lever ratios would give choices for pump stroke length and float size.

You could have two pumps, one each side of the pivot,

one pump forcing water as the wave rises,

one pump forcing water as the wave falls,

this would give a more continuous high pressure water flow.

You could make the beam somewhat 'bendy' (non-rigid)

to reduce the transmission of higher frequency energy to the pump.

For the environment,

make the float/raft suitable for the growth of a harvestable cash crop, e.g. shellfish

[Edited on 27-8-2019 by Sulaiman]

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Volitox Ignis

Hazard to Self

Posts: 53

Registered: 28-1-2016

Member Is Offline

Mood: No Mood

|

|

I like your ideas. What do you think about potentially putting another set of one-way valves on the bottom of the high-pressure cylinder, so that the

apparatus will also pump water out when the piston is descending?

I got two ideas for accounting for tides. One is to attach inflatable floaters to the setup at some point between the pump and the motor so that the

apparatus will always remain on the surface of the water. Of course, it would also be tethered to the sea floor by a cable.

Another idea I have is to attach the entire setup to a metal frame and then submerge the whole thing underwater. The frame would keep the piston above

the sea floor.

Thoughts?

|

|

|

Sulaiman

International Hazard

Posts: 3692

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

If the entire assembly is submerged then there will be no nett forces on the large piston

I see no fundamental problem with having valves operating on both the up and down stroke,

except that the linear/sliding bearing of the pump would need to be leak-proof at the operating pressure,

which would add cost, and probably lead to jamming of the piston shaft.

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

wg48temp9

National Hazard

Posts: 784

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

System Design 101

There is little point in asking which is best without specifying what characteristics are considered good ,what are considered bad and the

weighting/importance of each characteristics. Cost tends to be a primary factor in bestness. For example initial cost versus cost of maintenance. A

typical one dimensional cost is the cost of ownership for a given time say ten years. That cost could include the cost of maintenance over the ten

year life and could include estimates of inflation and exchange rate changes.

The first thing is to define the requirements meaning what does it need to do, for how long does it need to do it under what conditions, how can it

be maintained and how green and sustainability is it. Finally how many are required and what are the cost constraints.

So returning to the specific system of the OP's:

What it must do:

Pump sea water: at least several (what number is this) liter/day at 800psi to 1000psi using wave power.

How long does it need to do: ???

Environment/temperature: next to the sea, temperature range ??? (low temperature is important when pumping water)

Maintenance and reliability: ????

Cost: ???

Wave Power: ???

Discussion

The efficiency of the pump is obviously important but it can only be addressed when the available wave power is know in terms of time amplitude and

frequency. Additional will the fresh water be stored or will the pressured air or sea water be stored or is intermittent operation acceptable.

Turbines/pumps may have a narrow maximum efficiency flow range. Meaning the pumping power may drop to almost zero when the wave power is low but not

increase significantly for high wave power.

A different type of turbine/pump may have a broad maximum efficiency flow range that will still pump some sea water even when the wave power is low

So although the maximum efficiency may be lower than an alternative turbine/pump over the range of input wave power it may pump more on average. The

effect of the oscillatory input must also be considered.

The significance of cost can vary greatly. If the system is intended to be used on an expensive sailing boat cost my be less important while a system

to provide drinking water for third world communities living near the sea, low cost is critical.

QUICK CALCULATION

Say 5l/day at 1000psi. Thats 5l/(24*3600)= 0.06ml per second (very low). I don't think any kind turbine would be suitable.

1000psi is about 2300ft of water. Lets assume the wave height is one foot then the wave pressure must be increased by a factor 2,300 and considering

the wave shape lets say 4,600. In terms of diameters that is 68 to 1.

To be continued, sorry got to go

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|