Panache

International Hazard

Posts: 1290

Registered: 18-10-2007

Member Is Offline

Mood: Instead of being my deliverance, she had a resemblance to a Kat named Frankenstein

|

|

mechanical vacuum cutoff device

i use a large propane tank (1000mm x 300mm) as a vacuum reservoir for an aspirator system that is turned on/off from two locations via a standard 240v

solenoid valve.

I would like to supplement this system with a device that switches the solenoid on or off depending upon the vacuum in the tank without having to use

an electronic device as i find them quite unreliable for course vacuum work, as they get contaminated quickly. It should also be noted that i rely on

the reservoir as my safety bottle.

I have a float switch that i used to use on my large stil that reliably turns off the power when a certain height is reached, it is a commercial float

switch mechanism.

Does anyone have any ideas as to how could i use this existing mechanism to render a course but reliable vacuum cutoff/cuton?

if photos would help of the whole shebang as it currently exists i will gladly whack some up.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Here's something that would likely work, but it's probably more than you want to spend. Maybe it will give you some ideas.

http://www.dwyer-inst.com/Products/Product.cfm?Group_ID=268&...

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Panache  | | Does anyone have any ideas as to how could i use this existing mechanism to render a course but reliable vacuum cutoff/cuton? |

One of the earliest electric manostats, possibly the first, uses a mercury barometer, one electrode in the reservoir, and one at a

target pressure height.

|

|

|

densest

Hazard to Others

Posts: 359

Registered: 1-10-2005

Location: in the lehr

Member Is Offline

Mood: slowly warming to strain point

|

|

There are ways to protect a vacuum switch from contamination: absorbent traps, liquid U-tubes, diaphragms, filters, pinhole blocks, etc. Just putting

5 or 10 feet of capillary tubing between the tank and the switch might solve your problem. It would help if you knew what the contaminants were?

Gummy, corrosive, solvents, ??? Many of the switches use buna-N rubber diaphragms or O-rings so blocking substances that degrade rubber would probably

fix your problem. If it's something gummy then an inline trap filled with glass wool or equivalent would work. If it's vapor,, an absorbent trap and a

long line could help. It all depends on what the exact problem(s) are.

|

|

|

Panache

International Hazard

Posts: 1290

Registered: 18-10-2007

Member Is Offline

Mood: Instead of being my deliverance, she had a resemblance to a Kat named Frankenstein

|

|

Quote: Originally posted by watson.fawkes  | Quote: Originally posted by Panache  | | Does anyone have any ideas as to how could i use this existing mechanism to render a course but reliable vacuum cutoff/cuton? |

One of the earliest electric manostats, possibly the first, uses a mercury barometer, one electrode in the reservoir, and one at a

target pressure height. |

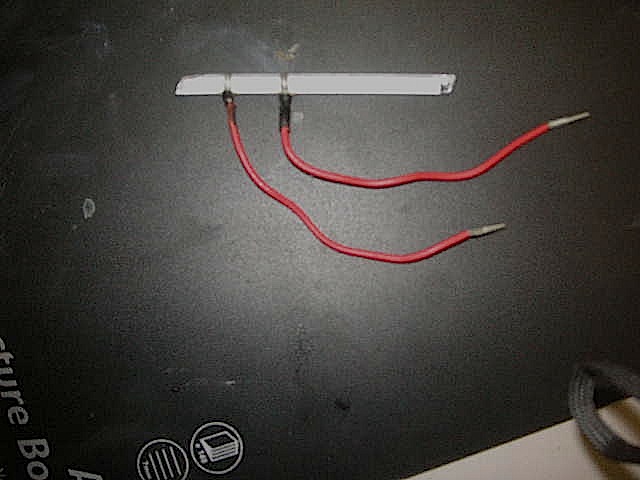

ah like this piece i have been saving for reference! this one is for temperature but the same deal applies i guess, i'll try that first, because its

ridiculously simple.

|

|

|

aonomus

Hazard to Others

Posts: 361

Registered: 18-10-2009

Location: Toronto, Canada

Member Is Offline

Mood: Refluxing

|

|

As terrible as this sounds, could you not open up a vacuum gauge, and add in a small microswitch to trip at a certain vacuum level?

|

|

|

Intergalactic_Captain

Hazard to Others

Posts: 228

Registered: 4-9-2004

Location: somewhere where i don\'t know where i am

Member Is Offline

Mood: frabjous

|

|

From what I gather, you want to control your current solenoid shutoffs electronicly via an electonic sensor? Sorry for the rambling explanation to

come, but I'm sure some members here are NOT renters and may appreciate it...

About 18 months ago, my water heater (gas) died and I had to figure out what was up. The last plumber that was called (while I was away, or I'd have

done the job myself) ended up charging us for $600 for what equated to babysitting a space-heater for 4 hours and replacing $12 worth of parts (and

"upgrading" a custom-made, milled, aluminum filter bracket with a piece of sheatmetal shit) - So, I said fuck it and decided to fix it myself.

Checked the valves and relays, everything in the controller circuitry, the powervent blower, all the tubing, and everything checked out fine....After

a day or two of head-scratching, I realized I missed only one thing - The pressure switch. You see, after pondering the schematics, I saw that when

the temp sensor kicked "on," the powervent turned on, which (should have) tripped the pressure switch, which then tripped a relay which opened the

main burner valve - Everything else was fine, so the weak link had to be the pressure switch... I pulled the tubing between the blower and the

switch, blowed into it, nothing... In a flash of insight, I sucked on it, and the main blower kicked on - Pulled the switch, disassembled it, and

weakened the spring (heated it with a lighter to kill the temper in the middle third of it)...Been working fine since then....

...So, that said, I'd look into something along the lines of a water-heater pressure switch. They are made in both positive and negative pressure

varieties, and can be modified incredibly easily by selectively weakening or replacing the spring. In this way, you'll have a robust, easy to install

switch (you'll still need a relay to your solenoid) that can be found relatively cheap on the second-hand market. It's electromechanical, but none of

the electrical circuitry will be "naked" in your setup - Just make sure the diaphragm material is compatible with your needs, though it shouldn't be

hard to diy one after you take a look at how they work...

If you see me running, try to keep up.

|

|

|

peach

Bon Vivant

Posts: 1428

Registered: 14-11-2008

Member Is Offline

Mood: No Mood

|

|

Here yar go, found this one years ago, enjoy me hearty.... ARRRRr.... can I get an arrrr on that arrr?

{edit}Incidentally, connecting a vacuum gauge to a 60ml syringe, I have managed to pull a100mBar and below vacuum with one pull of the plunger. And

produce over 100psi of positive pressure in the reverse direction. Actually, I managed 150psi, before the hose connecting the two looked like a

balloon.

[Edited on 6-10-2010 by peach]

|

|

|

Texium

|

Thread Moved

19-11-2023 at 16:06 |