xxxxx

Hazard to Others

Posts: 116

Registered: 21-5-2004

Member Is Offline

Mood: No Mood

|

|

beryllium piston rod and pin

beryllium is about as expensive as silver by volume, although it can be difficult to machine. for a small motorcycle or moped engine the cost of a

piston rod and pin made from beryllium would not be so much. i was wondering if there might be any benefits such as higher rpm, more power for

displacement and lighter total crankshaft weight and if these might be worth the additional cost.

|

|

|

pantone159

National Hazard

Posts: 590

Registered: 27-6-2006

Location: Austin, TX, USA

Member Is Offline

Mood: desperate for shade

|

|

| Quote: | Originally posted by xxxxx

if these might be worth the additional cost. |

and much more importantly, the extreme hazards of machining beryllium metal...

|

|

|

Nerro

National Hazard

Posts: 596

Registered: 29-9-2004

Location: Netherlands

Member Is Offline

Mood: Whatever...

|

|

It never occurred to you to look this up somewhere? Be is really toxic. The dication is smaller than He! It penetrates all biological barriers and

wreaks havoc in the cell.

#261501 +(11351)- [X]

the \"bishop\" came to our church today

he was a fucken impostor

never once moved diagonally

courtesy of bash

|

|

|

franklyn

International Hazard

Posts: 3026

Registered: 30-5-2006

Location: Da Big Apple

Member Is Offline

Mood: No Mood

|

|

There's no advantage with Beryllium over more mundane and readily

available Aluminum alloy rods. Aluminum Lithium alloy is used in some

high performance aircraft applications. http://en.wikipedia.org/wiki/Al-Li

Magnesium is less dense than Beryllium and it's alloys are stronger besides,

http://genchem.chem.wisc.edu/lab/PTL/ptl/Elements/Be/Be_Phys...

http://genchem.chem.wisc.edu/lab/PTL/ptl/Elements/Mg/Mg_Phys...

Beryllium is hardly used alone, most commonly in a spring alloy such

as Beryllium Copper and that is much denser.

The only real hazard Beryllium poses is inhalation of the dust -

http://www.irsst.qc.ca/files/documents/PubIRSST/Be-2005/Sess...

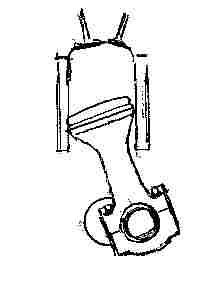

Below is a scheme I recall having seen though it has never been used

that I know. It is a one piece piston / rod that cants as it moves in

the cylinder. This was originally proposed as able to be made of some

reinforced polymer. This could really be lighter with some development.

Also with very high speed reciprocating bearings top and bottom of the

babbit must be a snug slip fit on the journal, the sides have larger

clearance than even normal bearings for increased lubrcation. This then

requires scrapers and a dry sump to reduce the oil and the viscous drag

it will cause. An engine is a unit, you change one thing and that in turn

affects the design of everything else in the system.

.

|

|

|