| Pages:

1

..

6

7

8

9

10

..

13 |

UncleJoe1985

Hazard to Self

Posts: 88

Registered: 30-9-2008

Location: Sunnyvale, CA

Member Is Offline

Mood: No Mood

|

|

| Quote: | | US1462987 suggests a 50:50 mixture of O2/N2 for better yield |

Actually, I was thinking of exploiting that since my 30mA current is relatively low. My idea was to electrolyze water and feed the oxygen to the

aquarium pump. I tried calculating the benefits of increased O2 concentration, but there's little theoretical benefit:

Page 583 of A Dictionary of Applied Chemistry gives the equilibrium constant of NO formation (N2 + O2 => 2 NO) as

k = (10^(0.5441 - 4725.5 / temperature))^2

To solve for the concentration of NO (mols/L) after going through the arc, I used

k = [NO]^2 / (([N2] - [NO] / 2)([O2] - [NO] / 2))

[N2] and [O2] are the initial atmosphere concentrations of nitrogen and oxygen. For non-chemistry experts like me, this is just a rate equation where the numerator on the right is the reaction rate of NO decomposition and the denominator is the rate of NO formation. The

subtraction accounts for the loss of 1/2 mole of O2 and N2 for each mole of NO produced in the equilibrium state.

At T = 3200K, the NO concentration will be 4.18% by molar fraction and volume as well, assuming gas is immediately cooled to STP.

Solving a similar equilibrium equation for 2 NO + O2 => 2 NO2, using the equilibrium of NO formation as the initial state and a very high

equilibrium constant (couldn't find it, but I'm pretty sure it's very high because it's exothermic), the final NO2

concentration will be 3.8% by volume.

Increasing the O2 concentration to 50% by volume resulted in a NO and NO2 concentration of 5.27% and 5.11%, not a large improvement.

Plus, the reported NO % in an industrial

setup is only reported as 1.5 - 2.0%, which is probably due to the NO decomposing as the gas is cooled. In that case, O2 becomes even less of a

limiting factor.

Of course, the k and T I used might not be accurate, or maybe a higher [O2] will help speed up the rates of reaction or help with reconverting NO,

created during NO2 absorption, to NO2. However, any improvement in [NO] will be canceled by NO decomposition when it cools, unless

you can quench it very fast. I did remember reading from some turn of the century text on Google books saying some Rayleigh reporting large

improvements in electrical efficiency from using a 50:50 N2, O2 mixture, which might not be from increased [NO], but couldn't find that source again.

I've also included a program for calculating my #s.

[Edited on 18-10-2008 by UncleJoe1985]

Attachment: NitricOxidesCalculator.java (4kB)

This file has been downloaded 1375 times

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by 12AX7

I find that suspect. Tungsten filaments *burn* in air. In fact, they literally produce a flame!

Filaments are a whole lot thinner than rods, much like powders are pyrophoric when the bulk material isn't, but still... |

That's because it's the tungsten itself that gets hot in filament form. With a tungsten electrode, only its point of contact with

the arc is subject to significant heating, and the thermal mass of the electrode acts to dissipate even that heat. TIG torches come in both air- and

water-cooled versions, since tip heating is, indeed, the limiting factor in electrode life.

|

|

|

UncleJoe1985

Hazard to Self

Posts: 88

Registered: 30-9-2008

Location: Sunnyvale, CA

Member Is Offline

Mood: No Mood

|

|

I didn't bother reading the patent jarynth mentioned before I did my calculations, but on the 1st page, it says a 50:50 N2, O2 mixture improves the NO

yield by 25%, exactly as I predicted. Damn, I feel smart!

|

|

|

UncleJoe1985

Hazard to Self

Posts: 88

Registered: 30-9-2008

Location: Sunnyvale, CA

Member Is Offline

Mood: No Mood

|

|

Fellow experimenters,

I've put together some pictures, video, and explanations for my procedures. Enjoy:

Some of the pictures are blurry. That's because the room doesn't have a lot of lighting and I didn't want to use the unnatural looking flash, so I

instead set the exposure to 1/80 s.

The video is separate because it's over the attachment size limit. Can any admin let me host it on this site?

A couple of notes:

1. The absorption column is just a 1.6L acrylic jar from Walmart that has grooves carved along the inner circumference with a Dremel tool to allow the

DVD layer to fit.

2. I used the smallest volume aquarium pump I could find. I think anything over will decrease the concentration of NO2 formed, unless I add more delay

between the arc and absorber. On the plus side, a higher air flow should quench the gas faster, allowing a higher concentration of NO to be locked in.

3. I'm not sure if the low climbing arcs are efficient. On one hand, they will reduce the amount of gas from re-entering the arc, but on the other

hand, higher climbing arcs are wider and are exposed to more air and also dissipate more power since they have larger resistance, though not as

intensely?

After running for probably 24 hours at least, I measured the HNO3 concentration by titration with 10% ammonia, using red cabbage indicator. I only had

a medicine dropper that had tick marks every 0.5mL, so the results aren't too precise:

2.25 mL acid to neutralize 0.5mL ammonia means

0.5mL * 0.9605g/mL * 0.1 * (1 mol NH3 / 17g) = 2.825 * 10^-3 mols NH3 neutralized = mols HNO3 neutralized

2.825 * 10^-3 mols / 2.25mL = 1.26 mols HNO3 / L

ammonia specific gravity

After concentrating it by boiling ~500mL to < 30mL, I measure the molar concentration again

0.8 mL 10% ammonia to neutralize 0.5 mL acid

= 9.04 mols / L

The weight % is just

9.04 mols / L * (63 g HNO3 / mol) * (1 L HNO3 / 1400 g) ~ 0.4

I didn't have the exact specific gravity of HNO3, so I just approximated.

So I went through all that effort to get 40% acid, while relatively inefficient, it suits my needs.

Any information on improving efficiency will be greatly welcome.

Fixed: zip file got corrupted during upload, also use VLC or mplayer to view the video. It seems QuickTime stutters.

[Edited on 21-10-2008 by UncleJoe1985]

Attachment: nitric_acid_reactor.zip (684kB)

This file has been downloaded 1232 times

|

|

|

497

National Hazard

Posts: 778

Registered: 6-10-2007

Member Is Offline

Mood: HSbF6

|

|

If you have read "Absorption of Nitrous Gasses" then you should have everything you need.. It's a good book, I read it nearly cover to cover (which I

don't do often). That 1% NO2 is sure hard to deal with...

My newest idea for easy concentrated nitric acid is directly from liquid N2O4 via the decomposition of calcium nitrate fertilizer (actually

5Ca(NO3)2*NH4NO3*10H2O). So far everything seems to look promising, I have tried the decomposition on a test tube scale and it worked nicely. At first

it melts in its own water of hydration, then after boiling part of the water off it suddenly precipitated into a pasty mixture that continued to give

off water. After some time the paste hardened a bit and the NH4NO3 decomposed. Then on further heating to about 550*C the mostly anhydrous Ca(NO3)2

melted again and gave off large quantities of 4NO2 + O2 until eventually only CaO was left. There are plenty of other nitrates out there that

decompose at much lower temperatures, but I can't buy them in 50 pound sacks... meaning I have to synthesize them and that adds so much work that I

find it easier just to use higher temperatures and Ca(NO3)2.

I think this could be done on a kilogram scale in a steel vessel heated with propane, or even wood, which I have tons of. Once substantial NO2

production starts you could attach a condenser cooled to -25*C or so and catch most of the N2O4. Once you have liquid N2O4 all you need to do is add

it in excess to water and bubble some oxygen (could be the byproduct O2 from another batch of N2O4  ) through it while stirring to get near 99% acid. N2O4 has many other wonderful uses including direct ozonization to

produce N2O5. It makes lovely binary explosives too. ) through it while stirring to get near 99% acid. N2O4 has many other wonderful uses including direct ozonization to

produce N2O5. It makes lovely binary explosives too.

Of course if you don't have calcium nitrate this isn't very useful, but seeing as most people in the US can get it for cheap ($25 per 50lb for me) it

seems like a useful method. Also it seems people are less suspicious of it compared to NH4NO3 or KNO3.

|

|

|

tentacles

Hazard to Others

Posts: 191

Registered: 11-11-2007

Member Is Offline

Mood: No Mood

|

|

497: It seems to me that Fe + molten Ca(NO3)2 is probably not going to work. Stainless steel might do the job, although I'd suggest 316 grade as it's

far more resistant to nitrate salt corrosion.

|

|

|

497

National Hazard

Posts: 778

Registered: 6-10-2007

Member Is Offline

Mood: HSbF6

|

|

You are correct, 316 would be a much better material to use. But, it is also more expensive and harder to get. The mild steel crucible will surely

corrode to some degree, but I suspect that it will be slow enough to allow it to be used at least a few times. Once it wears out I can just make

another one, I have plenty of steel around. If the corrosion turns out to be extremely fast, then I'll just have to figure out an alternative, but I

have a hunch it will be satisfactory. Of course before building a big crucible I'll test it on a smaller scale to find out.

[Edited on 21-10-2008 by 497]

|

|

|

chloric1

International Hazard

Posts: 1146

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

IIRC you need 3 moles of NOx with 1 mole of water based on this reaction scheme:

3NO2 + H20> 2HNO3 + NO^

The NO can be used to make more NO2, metal nitrosyl complexes, nitrites etc etc.

Fellow molecular manipulator

|

|

|

UncleJoe1985

Hazard to Self

Posts: 88

Registered: 30-9-2008

Location: Sunnyvale, CA

Member Is Offline

Mood: No Mood

|

|

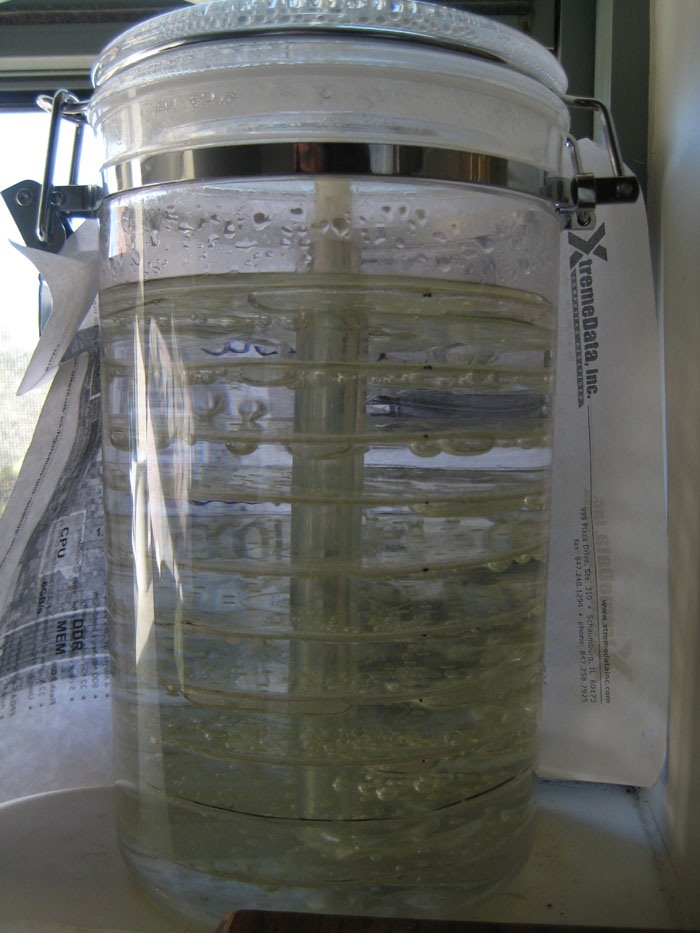

I've built a slightly larger absorption tower using a 2.1L acrylic jar from Walmart with 10 polycarbonate DVD layer trays. Adjusting the electrodes to

allow longer arcs, which are more efficient, I ran it for 28.6 hours.

The result is 1.5 L solution with a concentration of 1.28M = 8% by weight, which means I made ~4.1 g HNO3 / hour. Based on the efficiency of 65 g /

Kwh reported for industrial setups, my efficiency would be 24%, assuming I was drawing 260W on average (don't know very accurately).

One possible explanation could be poor gas absorption. Based on my experience, the concentration seems to peak out at 1.3 M. I've read somewhere that

it only takes ~5s for

3 NO2 + H2O => 2 HNO3 + NO

to reach completion, which I thought using 10 bubble layers would suffice. Of course 5s probably assumes the gas and water are very finely mixed,

which might not be in my case.

Another explanation could be maybe the 65 g / Kwh efficiency only accounts for the energy dissipated in the arc. In that case, my arc probably only

dissipates 135 W based on dann2's diagram (says ~1/2 voltage dropped across arc), which would raise the efficiency to ~50%. Anyone know the details?

I've included a new picture of the absorption column with bubbles evenly spread out. The sheet of paper is used to shield sunlight, which might

decompose the acid.

[Edited on 27-10-2008 by chemoleo]

Please use reasonable image sizes next time! Attached a smaller version.

[Edited on 26-10-2008 by UncleJoe1985]

|

|

|

497

National Hazard

Posts: 778

Registered: 6-10-2007

Member Is Offline

Mood: HSbF6

|

|

| Quote: |

Based on my experience, the concentration seems to peak out at 1.3 M. I've read somewhere that it only takes ~5s for 3 NO2 + H2O => 2 HNO3 + NO

to reach completion, which I thought using 10 bubble layers would suffice. Of course 5s probably assumes the gas and water are very finely mixed,

which might not be in my case. |

That may be, but it takes much longer to fully oxidize the resulting NO back to N2O4. So you are probably losing about a third of your yield..

Since your N2O4 is so dilute you're never going to get very concentrated acid straight from the absorber, you might as well not try, it will just make

for more effort and loss of yield.

If I were going to make an efficient absorber I would use a cheap submersible aquarium pump with the output air from the arc plumbed into the venturi

inlet (this would actually have enough suction to pull the air through the whole system). The pump would then be set in the bottom of a 5 gallon

bucket and aimed so as to produce a spiral water movement. The bucket would be about 1/2 to 2/3 full and ideally would have a sealed lid that was then

plumbed into a second venturi in a second bucket (that could be smaller). The air space will allow some residence time for things to get fully

oxidized. This setup should handle quite a bit of N2O4. With your amount of N2O4, you could set it up to run for weeks at a time.

For reducing the absorber size and complexity and/or increasing your yield I would recommend using dilute H2O2 as your absorption media. It will work

much faster and catch almost all the N2O4. Each gram of H2O2 will absorb 2.7g N2O4, so a liter of 2% will absorb about 54g (making 74g HNO3) at high

efficiency. If you have ready access to more concentrated H2O2 then by all means use that, it will work even better.. Or you could run the (cold)

output gas through an ozonizer, this is said to greatly improve absorption by forming N2O5 in situ.

|

|

|

UncleJoe1985

Hazard to Self

Posts: 88

Registered: 30-9-2008

Location: Sunnyvale, CA

Member Is Offline

Mood: No Mood

|

|

| Quote: | It takes much longer to fully oxidize the resulting NO back to N2O4 ...

The air space will allow some residence time for things to get fully oxidized. |

Yeah, I found that too from the same publication (attached) that reported the NO2 + H2O equilibrium of ~5s (figure 2). I guess using an additional 5

bubble layers compared to my previous setup isn't worth much because most of the NO2 is already absorbed, while the NO still doesn't have enough time

to react.

I imagine adding a delay space between a second absorption column will work well in the same way as I added a delay chamber in between the arc furnace

and the 1st absorption column. However, I'm hesitant to do so yet because I'm using a relatively weak aquarium pump that probably will reduce its flow

under higher load. I have a more powerful one, but it's probably too powerful - it breaks the arcs before they stretch to the max. Plus, the higher

pressure might cause more leakage - the epoxy on top of my furnace gets soft when it's on and there's a funny smell, probably ozone.

| Quote: |

use a cheap submersible aquarium pump |

I probably could use it and go up to 30% acid before the plastic gets attacked, but I'm worried that the moving parts (e.g. check valve) aren't acid

resistant.

| Quote: | | I would recommend using dilute H2O2 as your absorption media |

Looks promising, considering that 1L H2O2 is only 97 c.

[Edited on 26-10-2008 by UncleJoe1985]

Attachment: no2_equilibrium.pdf (835kB)

This file has been downloaded 1250 times

|

|

|

497

National Hazard

Posts: 778

Registered: 6-10-2007

Member Is Offline

Mood: HSbF6

|

|

The kind of submersible pump I'm talking about has only one moving part: the impeller. Some have all plastic exposed surfaces, it depends on the

brand.

Plastic being attacked by dilute HNO3 could be a problem, I don't know how fast it proceeds..

You can even bubble the gas into the intake of the pump and the impeller will chop the bubbles up extra fine, at the cost of some water flow.

The ultra fine bubbles will allow the absorption to be nearly instant, the oxidation of NO being the limiting factor.

According to Absorption of Nitrous Gasses it takes 180 seconds to oxidize 90% of the NO in a 1% NO-air mix.

To get 98% oxidized it takes 1014 seconds.. So you need to adjust your residence times accordingly.

Note the graph applies only to mixtures not in contact with water, which changes the whole dynamic.

When lots of water is present the NO gets oxidized to N2O3 (which takes much less time) and it then absorbed as HNO2.

Later over time this HNO2 will break down again releasing 2/3 of the nitrogen via

3HNO2 > 2NO + HNO3 + H2O

and causing some loss. So ideally your oxidation chamber is separate from the absorbers.

PS. Do you have affordable access to a nitrate fertilizer such as calcium nitrate, etc?

[Edited on 26-10-2008 by 497]

Attachment: NO oxidation.doc (75kB)

This file has been downloaded 1075 times

|

|

|

UncleJoe1985

Hazard to Self

Posts: 88

Registered: 30-9-2008

Location: Sunnyvale, CA

Member Is Offline

Mood: No Mood

|

|

OK, I've found the reference to higher [O2] => greater efficiency. It's on page 36 of this book. In general, the book is a very good survey and many of my experimental results are confirmed by it. Since the increase in efficiency is

probably not due to higher [NO] created by the arcs, my guess would be that it is due to improved oxidation of [NO] after leaving the arc and after

being produced during absorption (3NO2 + H2O => 2HNO3 + NO).

[Edited on 26-10-2008 by UncleJoe1985]

|

|

|

UncleJoe1985

Hazard to Self

Posts: 88

Registered: 30-9-2008

Location: Sunnyvale, CA

Member Is Offline

Mood: No Mood

|

|

497:

| Quote: |

it takes 180 seconds to oxidize 90% of the NO |

Wow, I never knew it was that long. The gas in my delay chamber is moderately dark, so I thought I gave it enough time. This explains the height of

the absorption columns I calculated earlier. In light of this, I should make my first delay chamber even larger.

I probably can get nitrate fertilizer and make HNO3 cheaper the old school way, but haven't looked where to get it yet. I'm a M.S. in computer science

/ CSE at Georgia Tech and I'm mostly doing this out of curiosity and its minimal reliance on chemicals - only air, water, and electricity! I mostly

frequent ACE hardware, Walmart, and Target and try to build everything from commodity parts, which takes ingenuity.

[Edited on 26-10-2008 by UncleJoe1985]

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

UncleJoe, in your picture (which I reduced in size), you could put in a magnetic stir bar at the bottom, and stir the whole thing at high speed. This

will break up bubbles into many small ones, keeping them in suspension for a long time, and therefore should increase absorption drastically.

Also, if you are going to discuss thermal decomposition of nitrates, please do so in a separate thread - I'll happily move the existing posts in

here...

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

497

National Hazard

Posts: 778

Registered: 6-10-2007

Member Is Offline

Mood: HSbF6

|

|

| Quote: |

you could put in a magnetic stir bar at the bottom, and stir the whole thing at high speed. |

That's not a bad idea. Alternatively, if you don't have a magnetic stirrer set up, you might be able to rig up a mechanical stirrer with the shaft

down the center. But really, with the small amounts of N2O4 he's dealing with, I don't think absorption area is the problem, residence time is the big

issue. In Absorption of Nitrous Gasses the author puts much emphasis on the free space in the absorption tower packing. Ideally it is upwards

of 80% free.

If someone wants to discuss decomposition of nitrates I'm all for it.. however the mods want to set it up.

[Edited on 26-10-2008 by 497]

|

|

|

OMG

Harmless

Posts: 15

Registered: 26-7-2008

Location: BC, Canada

Member Is Offline

Mood: No Mood

|

|

If one was inclined, could you absorb the NOx into say a NaOH filled filter? Would that be a better way to capture and concentrate nitrates

generated? Then maybe use sulfuric to make concentrated nitric after that.

|

|

|

kclo4

National Hazard

Posts: 916

Registered: 11-12-2004

Location:

Member Is Offline

Mood: No Mood

|

|

You'd have the problem of Sodium Nitrite forming. Also, the NaOH might liquefy from the H2O produced, the H2O in the air, and also the Sodium

Nitrite/Nitrate Mixture would prevent a lot of the NOx from reacting with the NaOH since it might coat the particles.

Another thing to consider is you'd also have to then react that with a strong acid, which might be though of as wasteful since reacting NOx with water

doesn't use a strong acid, but it produces one.

If you were to just react a Nitrate with a strong acid, you'd be better off getting nitrates from the organic waist/dirt. there are a few references

on the forum about this process.

But I think the purpose of this thread is more directed towards turning Air and Water directly into Nitric acid.

|

|

|

Formatik

National Hazard

Posts: 927

Registered: 25-3-2008

Member Is Offline

Mood: equilibrium

|

|

| Quote: | | Originally posted by UncleJoe1985 The video is separate because it's over the attachment size limit. Can any admin let me host it on this site? |

That's a creative idea how to have used those CD protectors to better facilitate gas absorption. I would have never thought of that.

|

|

|

kclo4

National Hazard

Posts: 916

Registered: 11-12-2004

Location:

Member Is Offline

Mood: No Mood

|

|

I wish to watch your video, since it seems pretty interesting but it randomly starts speeding up.

Even after I downloaded it, it still does that! I wonder why?

Either way, I really like how your project is going.

You've inspired how I plan to absorb some gases from now on!

|

|

|

UncleJoe1985

Hazard to Self

Posts: 88

Registered: 30-9-2008

Location: Sunnyvale, CA

Member Is Offline

Mood: No Mood

|

|

Formatik,

I didn't use CD protectors - didn't know they existed until now. I split DVDs in half and used the non-label polycarbonate layer. The top layer

fractures too easily. HCl was used to dissolve any aluminum and organic dye.

My idea probably isn't too original. I was intentionally trying to build the bubble cap trays used in an industrial setup. What is original is using

DVDs - finally, something useful to do with all those junk CDs and DVDs.

Earlier, I tried using plastic mesh pot scrubbers, but they failed miserably because they weren't held in place and large bubbles just went through

any gaps. I think I'll try it again, now that I can secure them between the layers.

KCLO4,

Thanks for watching. Unfortunately, QuickTime has flaky H.264 high profile support or my encoder has a bug. I don't have the original source, so I

can't reencode it. It plays fine in VLC player or if you don't want to install it, play it in Adobe Flash (wow, never knew Flash Player can play stand alone videos).

Also, what size power supply will you use? My power supply is relatively small and I would like to see how well things scale up. The pump will need to

be more powerful and the delay chamber needs to be larger to compensate for the increased flow.

[Edited on 27-10-2008 by UncleJoe1985]

|

|

|

Formatik

National Hazard

Posts: 927

Registered: 25-3-2008

Member Is Offline

Mood: equilibrium

|

|

I see. I was thinking of those colorless CD protectors that come with sets of empty CDs or DVDs. One could also puncture those wether by a tool or

heat.

|

|

|

UncleJoe1985

Hazard to Self

Posts: 88

Registered: 30-9-2008

Location: Sunnyvale, CA

Member Is Offline

Mood: No Mood

|

|

Here's some more data I measured after getting up today:

The concentration is now 1.61 M = 9.6% after running an additional 18.8 hours which means 1.6 g / hour HNO3 produced over that span and 3.1 g / hour

if counting from the beginning. Moderately thick white fumes came out when I opened the top of the jar.

Any ideas on why the absorption goes down so much? An industrial setup can achieve 40% acid before diminishing gains.

Also, I'm starting to doubt the accuracy of my concentration measurements using titration. I'm worried about how much HNO2 affects the measurement. If

all the HNO2 eventually converts to HNO3, then the titration end point should accurately measure [HNO3]. It's tempting to think that the [H+] measured

comes almost exclusively from HNO3 since very little HNO2 ionizes in water (k = 4.0 x 10-4), but as the acid is neutralized, any unionized HNO2 will

ionize until all of it is gone. Anyone know the %s of HNO2 and HNO3 in a typical setup?

[Edited on 27-10-2008 by UncleJoe1985]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Commercial towers are run at 100 psig and have interstage coolers. But I think you already know that.

| Quote: |

Anyone know the %s of HNO2 and HNO3 in a typical setup?

|

Is your product slightly blue in color? I think if there was any significant HNO2 it would be a faint clear blue. One job I worked on used a packed

column (Intalox saddles IIRC) to absorb waste NOx from metal dissolution to prevent air pollution. The column was about 6" in diameter and a couple

stories high. The product had a beautiful faint blue tint. Sorry I can't remember the molarity of the product or whether the column was pressurized.

Maybe I can find out from one of my old colleagues.

Edit: I don't think the column was pressurized and we didn't care about the product molarity. It was just a waste product. What we cared about was

the ppm NOx in the effluent gas. This had to meet state discharge requirements.

What you have constructed is a sieve tray tower. It is a clever use of Wal-Martian material. You might also try a packed column. Little saddles of

some kind might be ideal. I don't know what the equivalent Wal-Mart stand-in would be, however.

[Edited on 27-10-2008 by Magpie]

[Edited on 27-10-2008 by Magpie]

|

|

|

UncleJoe1985

Hazard to Self

Posts: 88

Registered: 30-9-2008

Location: Sunnyvale, CA

Member Is Offline

Mood: No Mood

|

|

No, the 1.6 M acid is very light yellow, too pale for my camera to capture.

|

|

|

| Pages:

1

..

6

7

8

9

10

..

13 |