4.6. Synthesis of 4-methoxyphenol-d7

To a solution of 1,4-hydroquinone-d6 (9) (98 atom% D, 4.48 g,

38.6 mmol) and benzoquinone-d4 (98 atom% D, 325 mg,

2.90 mmol) in methanol-d4 (99.8 atom % D, 25 mL) was added sul-

furic acid (4.80 g) over 5 min at room temperature. The reaction

mixture was stirred for 14 h, poured into ice-water and neutralized

with 4 M aqueous NaOH. The aqueous solution was extracted with

Et2O. The organic layer was washed with brine, dried over Na2SO4

and concentrated in vacuo. The residue was purified by silica gel

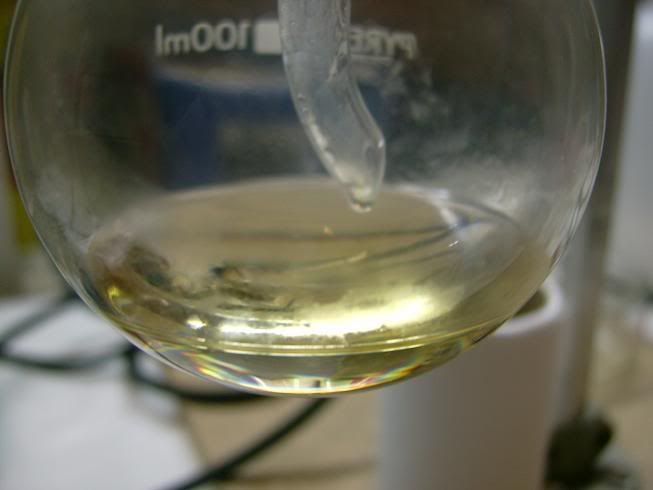

column chromatography (n-hexane/EtOAc = 5:1) to give 3 as a pale

yellow solid (4.83 g, 95%): 1H NMR (400 MHz, CDCl3) d 3.72–3.76

(m, 0.06H), 4.87 (s, 1H), 6.76 (s, 0.10H), 6.79 (s, 0.10H); 13C NMR

(100 MHz, CDCl3) d 55.06*, 114.59*, 115.80*, 149.41, 153.48; IR

(solid sample): 3381, 2521, 2262, 2069, 1419, 1141, 1112 cmÀ1;

HRMS (EI): m/z [M+] calcd for C7HD7O2: 131.09564; found:

131.09642; mp 56–57 °C. |

which is absurd. Why would an electrophilic center react with an electrophilic center?

which is absurd. Why would an electrophilic center react with an electrophilic center?

).

).

).

).