Since you have access, would it be possible for you to run GC/MS on the initial benzyl alcohol? I have some USP stuff and also some of the KYAntec

stuff. The USP grade is water clear but as you know the KYA stuff is an amber color. I'm wondering what the impurities are in that, and if that

contributed to the byproducts in the product?

EDIT:

If anyone is interested in the potential of this method, check out this paper:

Looks like you can pretty much mix 1:0.625 BnOH:HNO3 of 10% concentration, heat it for a couple hours with a pinch of NaNO2, and get like 95% BzH

yield. Nice!

The paper shows that high concentrations of nitric acid reduce yield. At low concentrations of nitric acid the reaction does not require cooling, and

in fact needs additional heat.

A procedure from the paper:

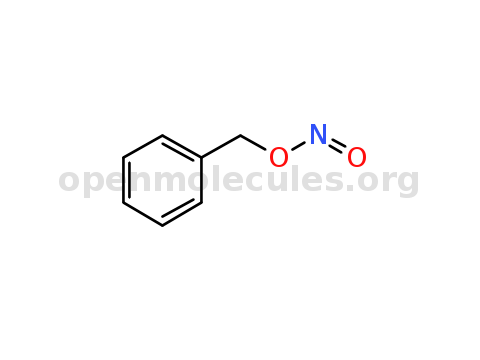

0.3 mol benzyl alcohol is charged into a flask with 1g NaNO2 and 118mL of 10% aqueous nitric acid preheated to 90°C. This is stirred as rapidly as

possible and kept at 90°C for 4 hours. The final product shows >86% conversion of the benzyl alcohol to benzaldehyde and benzyl nitrite, with a

yield of >95% for benzaldehyde and <1% for the nitrite, with <5% unconverted alcohol.

[Edited on 5-2-2017 by Praxichys] |