3 )

Halogens will replace hydrogen attached to nitrogen

Here are current applications of Fluoro amines

http://www.pat2pdf.org/patents/pat6395899b1.pdf

http://www.pat2pdf.org/patents/pat6417355b1.pdf

Hexachloromelamine

http://pubchem.ncbi.nlm.nih.gov/summary/summary.cgi?cid=1705...

This appears to be an explosive given the dichloramine groups.

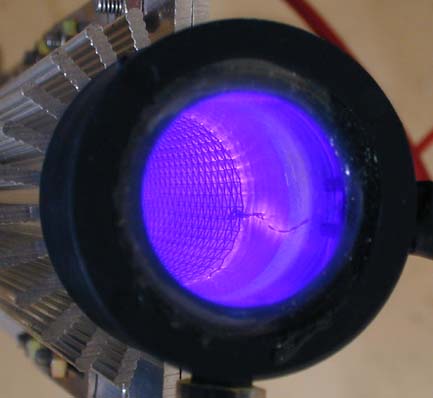

Figure 1

Figure 1 Figure 2

Figure 2 Figure 3

Figure 3  Figure 4

Figure 4