I just finished drying my run of naphthionic acid and was about to do a quick writeup when I saw this thread! I guess the timing worked out well,

might as well post what I've got.

<b>Experimental</b>

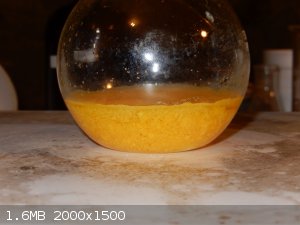

4.7g of α-nitronapthalene was placed in a 250ml flask. This was a slightly darker yellow than pure α-nitronaphthalene, but as the paper mentioned

above(Magpie's ref. 1) uses the nitro compound crude and this was recrystallized once, it was deemed pure enough.

<i>α-nitronapthalene</i>

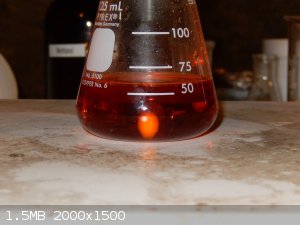

13.23g of Na<sub>2</sub>S<sub>2</sub>O<sub>5</sub> were then weighed out and dissolved in 50ml of distilled water.

This solution was then added to the flask containing the nitro compound and a condenser was attached.

<i>Reaction mixture prior to heating</i>

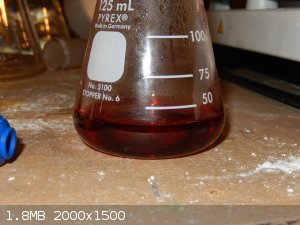

The mixture was heated to reflux with magnetic stirring, at which point it was noted that the nitronaphthalene melted and floated above the aqueous

layer. Complete dissolution occurred after about 4 hours, and heating was continued for another half hour to ensure complete reaction.

<i>Reaction mixture refluxing near the end of the reaction</i>

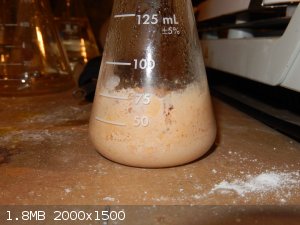

The mixture was then allowed to cool slightly below reflux, at which point the condenser was removed and heating was reapplied until approximately one

quarter of the solution had evaporated.

<i>Reaction mixture prior to evaporating water</i>

<i>Reaction mixture after evaporating water</i>

11ml of 32% hydrochloric acid were then added(This slightly more dilute acid was used because I didn't have conc. HCl on hand) while the mixture was

still hot. This resulted in effervescence of some SO<sub>2</sub>, thus this preparation should be conducted in a well ventilated area.

Immediate precipitation of a tan solid was noted. The solution was then left to cool down to room temperature, at which point it had nearly

completely solidified.

<i>Acidified reaction mixture cooled to room temperature</i>

Since the mixture was not filterable at this point, 40ml of hot water(This water is used in ref. 1 to wash the product in the funnel) were added and

the mixture was shaken vigorously until the solid was broken up enough for the magnetic stir bar to be freed, at which point the mixture was stirred

for several minutes.

<i>Naphthionic acid suspended in water</i>

The solution was then vacuum filtered and the solid was washed with an additional 15ml of distilled water.

<i>Naphthionic acid filter cake</i>

This was allowed to dry in the funnel overnight, at which point it was removed, then placed on a watch glass. This was then placed on a hot plate at

140°C surface temperature for several hours to dry completely, then ground into a powder, yielding 3.62g of naphthionic acid as a pale pink/tan

powder.

<i>Final product of naphthionic acid</i>

<b>Discussion</b>

The yield for this reaction was 3.62g or 59.7%. I'm quite confused by this high yield, considering both ref. 1 and ref. 3 above mention 20-30% yields.

Initially I assumed that the increased yield was a result of the stirring, however this seems to be in line with what Magpie obtained, so I have a

feeling that the product is contaminated with sodium chloride, or an organic byproduct. I'm not sure why though, as I washed with more water than the

procedure recommended. If anyone has any ideas as to why the yield is high, or a method of going about testing my product I'd be more than willing to

try it. Perhaps a chloride test with AgNO<sub>3</sub> will work, but I don't have any solubility data on silver naphthionate, so it

wouldn't be terribly useful. MP is out of the question as well, due to the 300°C+ MP of naphthionic acid.

[Edited on 5-27-2016 by gdflp]