Yes, I confirm this procedure. FeSO4 + H2SO4 + H2O2 + (NH4 )2SO4 really works fine.

I used to make larger amount ( ~ 200g) of this alun.

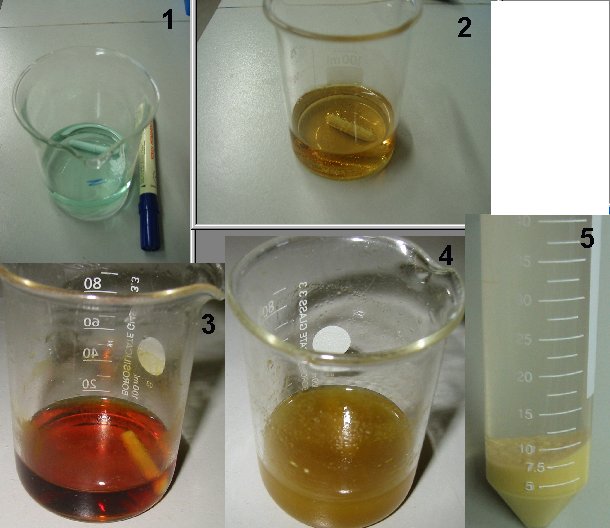

Indeed, from deep brown solution small white crystals are formed.

On the picture - mentioned alun.

It is almost coloreless, with a little amethyst (~violet) shade.

ps. my fellow made (in similar way) beautiful, large (> 1 cm), bright violet crystals of Fe(III) sulfate ( x 9 H2O).

ps2. with aid of ~5% acidic solution of K3[Fe(CN)6] you can test presence of Fe(II) in your oxidated solution. When Fe(II) ions are present, deep blue

colour/precipitate appears when you mix ferricyanide sol. with tested sol. It is very sensitive test. When only Fe(III) ions are present, mixing gives

clean brown solution.

[Edited on 8-9-2008 by kmno4] |