)

)

| Quote: |

| Quote: |

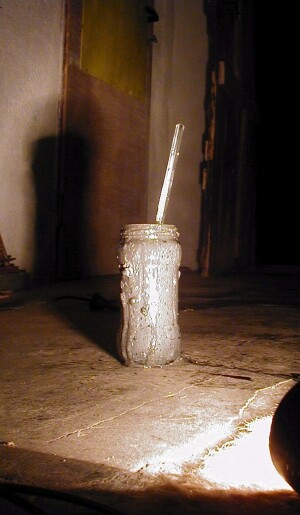

Worked perfect. Two minutes on full power and it was running almost too fast and hot. (I saw it to late kicking in as

a plasticbag attached as gas and acidcatcher got in the way and hindered my sight).

Worked perfect. Two minutes on full power and it was running almost too fast and hot. (I saw it to late kicking in as

a plasticbag attached as gas and acidcatcher got in the way and hindered my sight).

), there is no doubt for me that this will

work even better as sheets.

), there is no doubt for me that this will

work even better as sheets.

| Quote: |