akre - 28-1-2006 at 11:23

I know sulfuric acid production has been covered in some other threads before. Anyway I'm going to try building a sodium sulfate electrolyzer.

I was thinking of a design with three PP tubes. Two 50mm tubes inserted into a 110mm tube. The smaller tubes are going to be half the length of the

larger tube. Above the tubes extending upwards I was thinking of filling the space with some kind of ion conducting material, like concrete or plaster

with two holes extending form the two tubes below. The tubes would be filled with carbon.

Does anyone have any experience with plaster or concrete as an ion membrane?

I'll post a drawing later showing the design I was thinking of.

12AX7 - 28-1-2006 at 14:15

I don't know about plaster but concrete is specifically rated as "non sulfate resistant". The masonry used in smoke stacks uses sodium silicate based

mortar for this reason.

Tim

akre - 31-1-2006 at 09:58

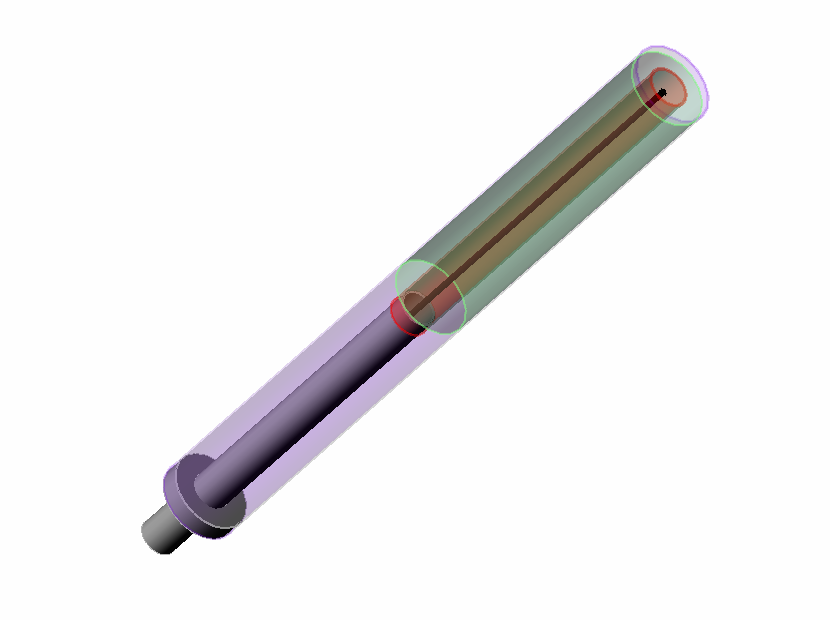

I've made a first drawing of the electrolyzer. The design is changed to only use two tubes, the centre tube serving as the anode compartment. The

reddish tube at the top is the ion membrane, the green cathode is made of stainless steel.

BalancedWorld - 3-2-2006 at 20:39

Why don't you use a car battery.?

akre - 4-2-2006 at 13:43

Use a car battery? For what? Recovering the acid?

I still need some ideas for making the diaphragm. Does anyone have some ideas for testing the performance of such a diaphragm?

[Edited on 4-2-2006 by akre]

BalancedWorld - 6-2-2006 at 04:00

"Use a car battery? For what? Recovering the acid?"

A car battery has a diaphragm designed for HSO4, the case is resistant to the acid, it has electrodes inplace.

Whats missing?

Cut around were the lid and base come together. Make sure it can fit back together nicely. Replace the stuff inside the plastic looking bag with

LeadSO4 and water.

When chargeing you should get 2LeadOH and H2SO4.