Just another oxidiser - Manganese-(III)-sulfate

by: hermanroempp

Process for the preparation of an oxidiser:

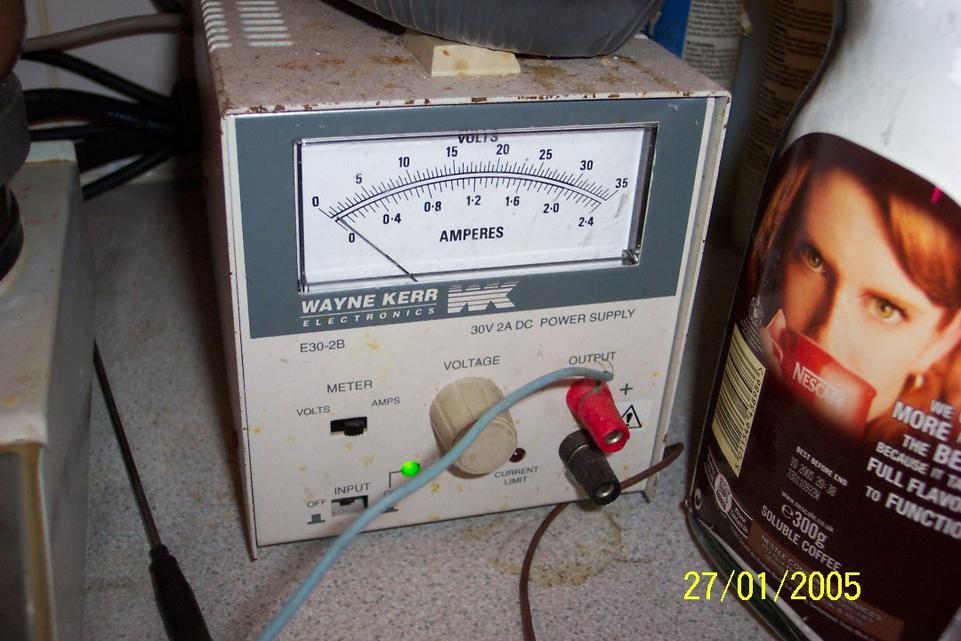

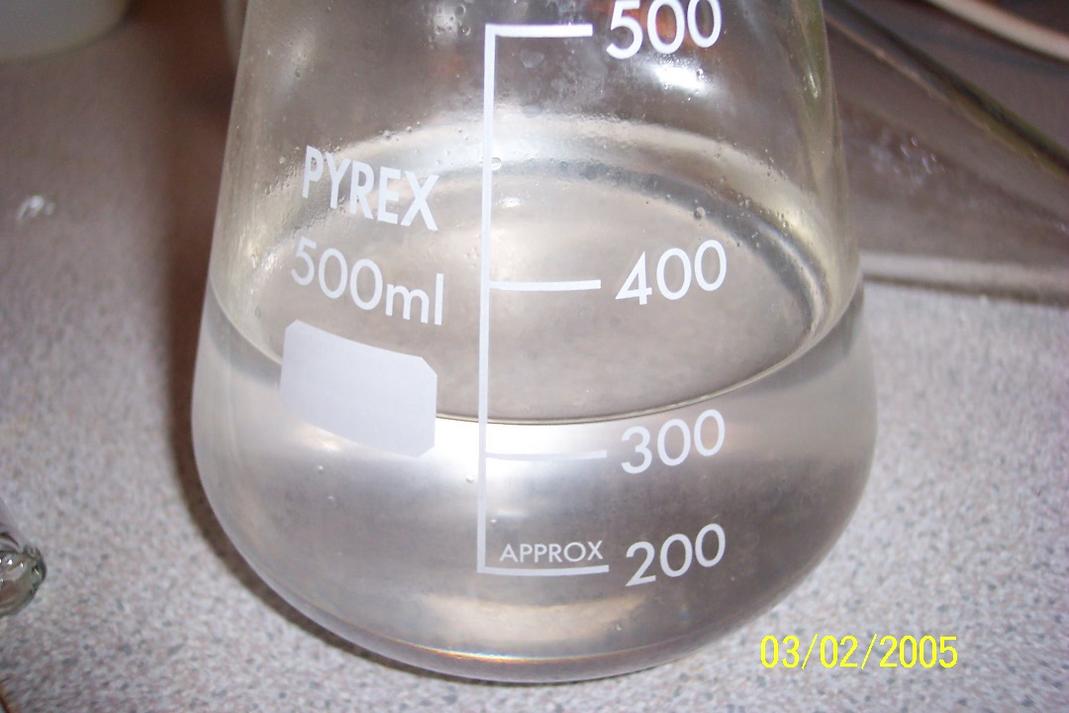

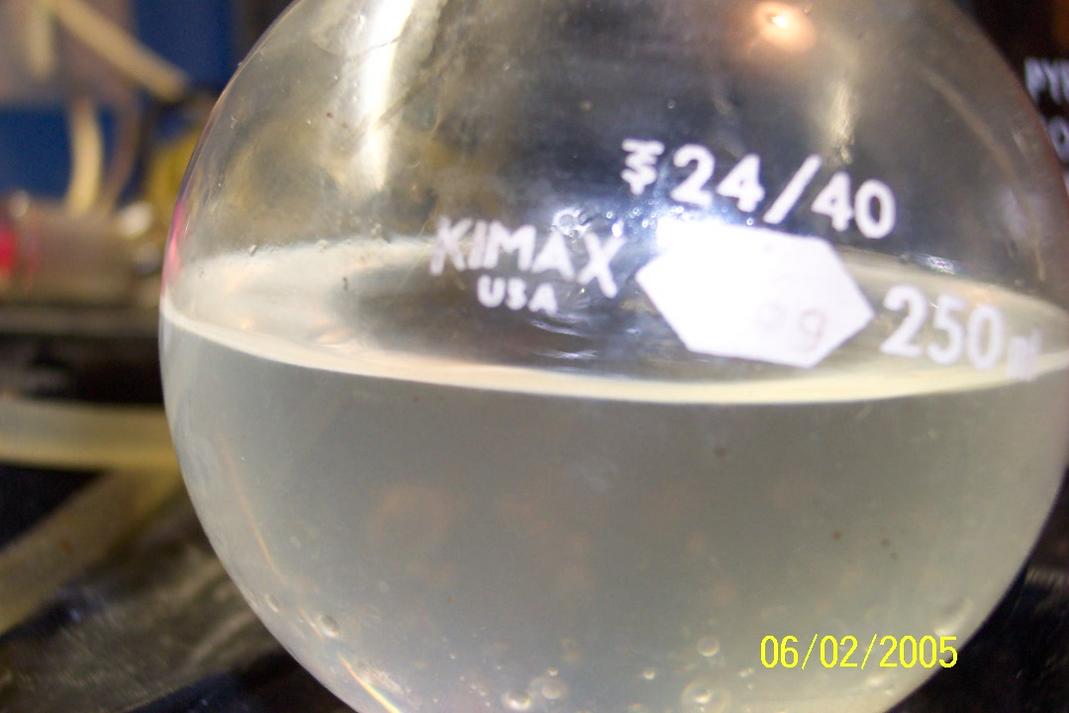

The process implies the dissolution of manganese-IV-dioxide in sulfuric acid of 50-60% strength in the presence of manganese-II-sulfate. To obtain the

oxidiser as a solid, a cold saturated solution of manganese-II-sulfate in water is prepared and concentrated sulfuric acid is added (with cooling, of

course) until the solution contains 50-60% sulfuric acid.

The purpose of precipitating the manganese-(II)-sulfate by addition of sulfuric acid is to get the sulfate in finely divided particles, but finely

ground manganese-(II)-sulfate could also be used with the same results.

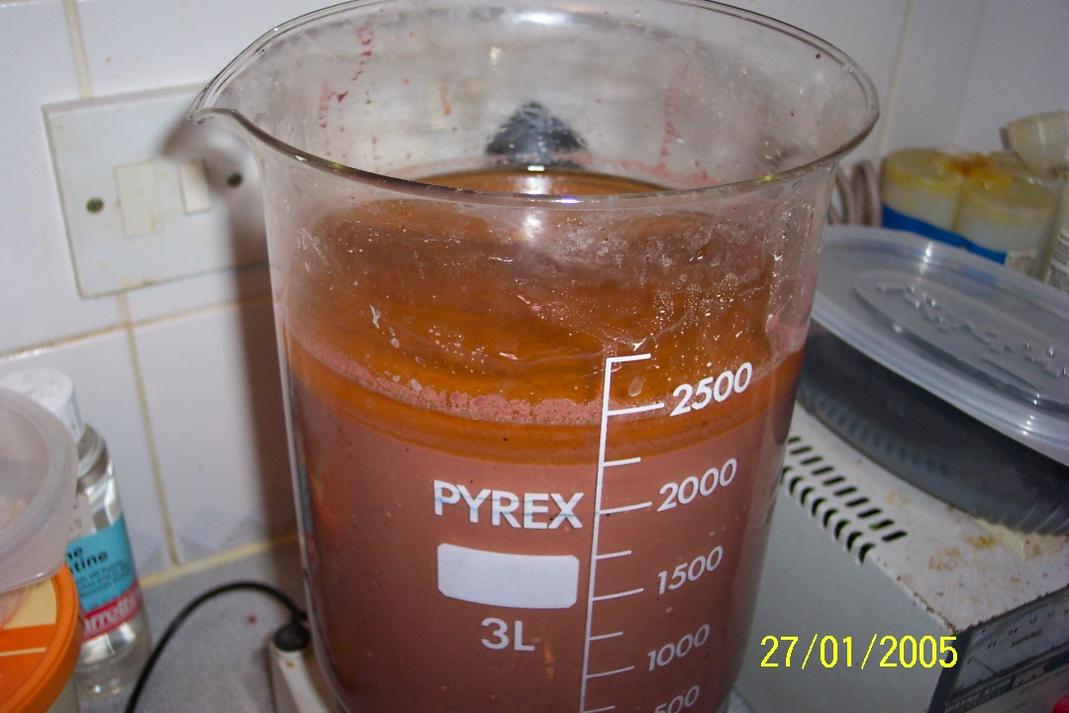

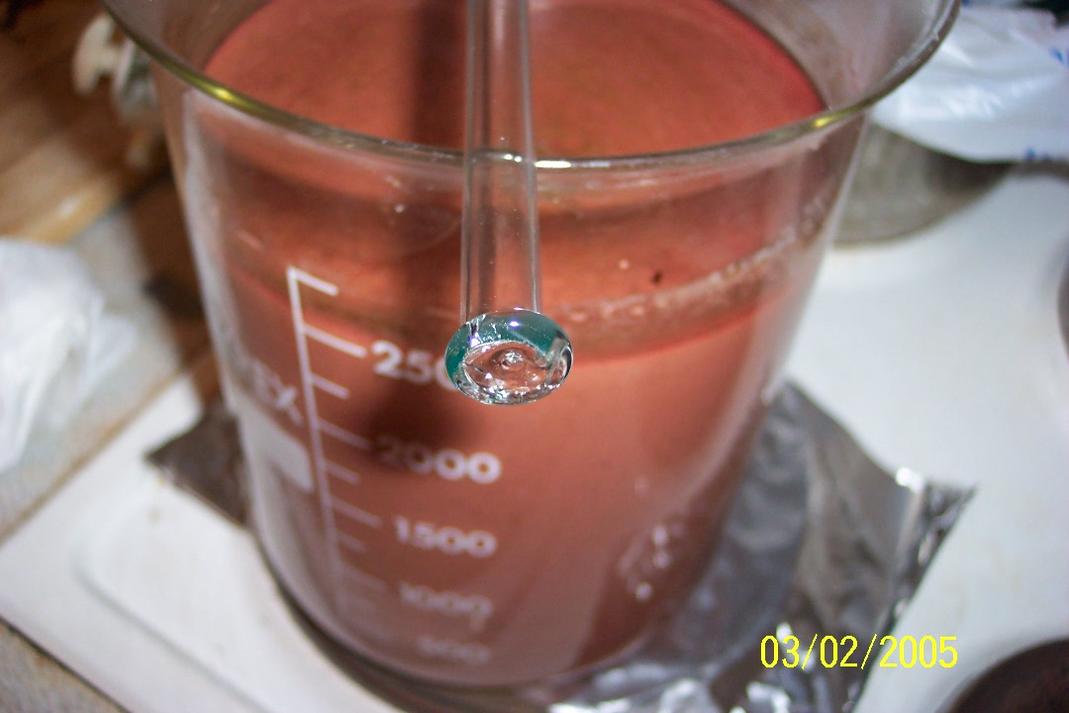

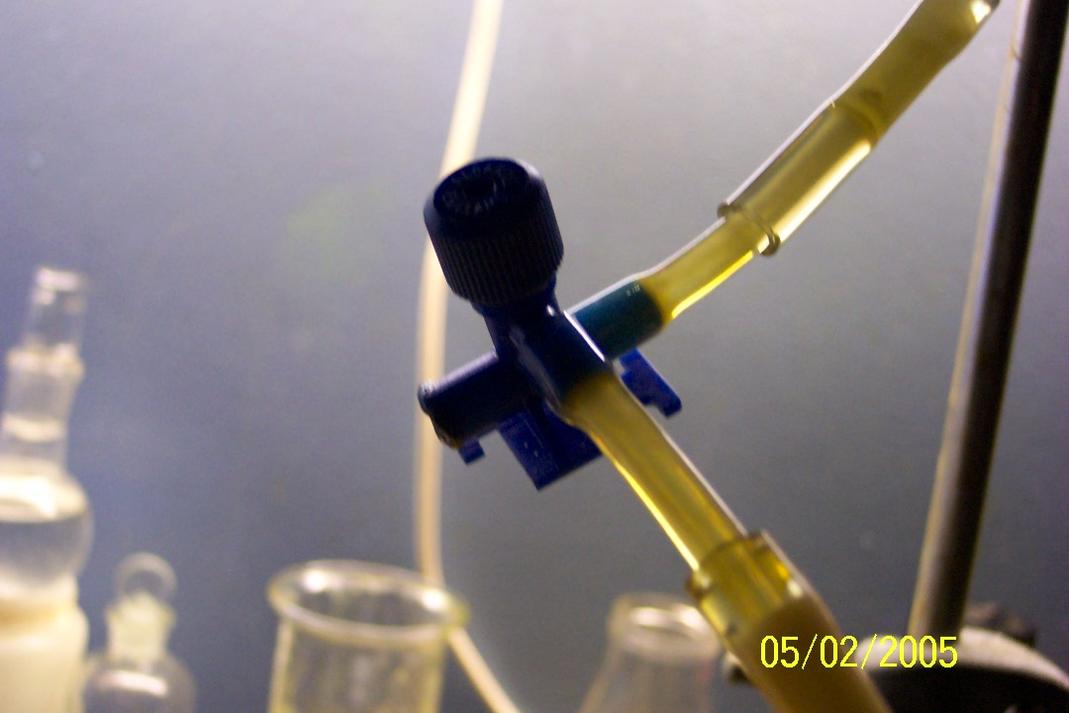

To the crystalline sludge such obtained an equimolar part of manganese dioxide is added under strirring, i.e. for 1 Mol MnSO4 1Mol MnO2 is added. The

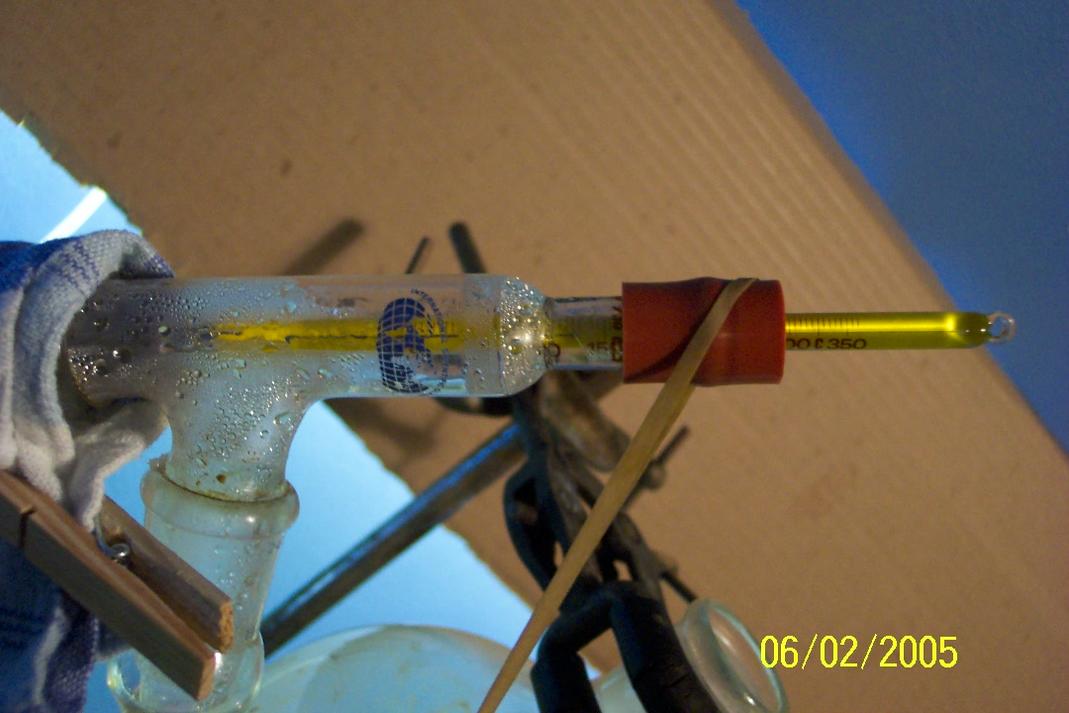

slush is stirred until the manganese dioxide has dissolved under warming (the reaction is exothermic).

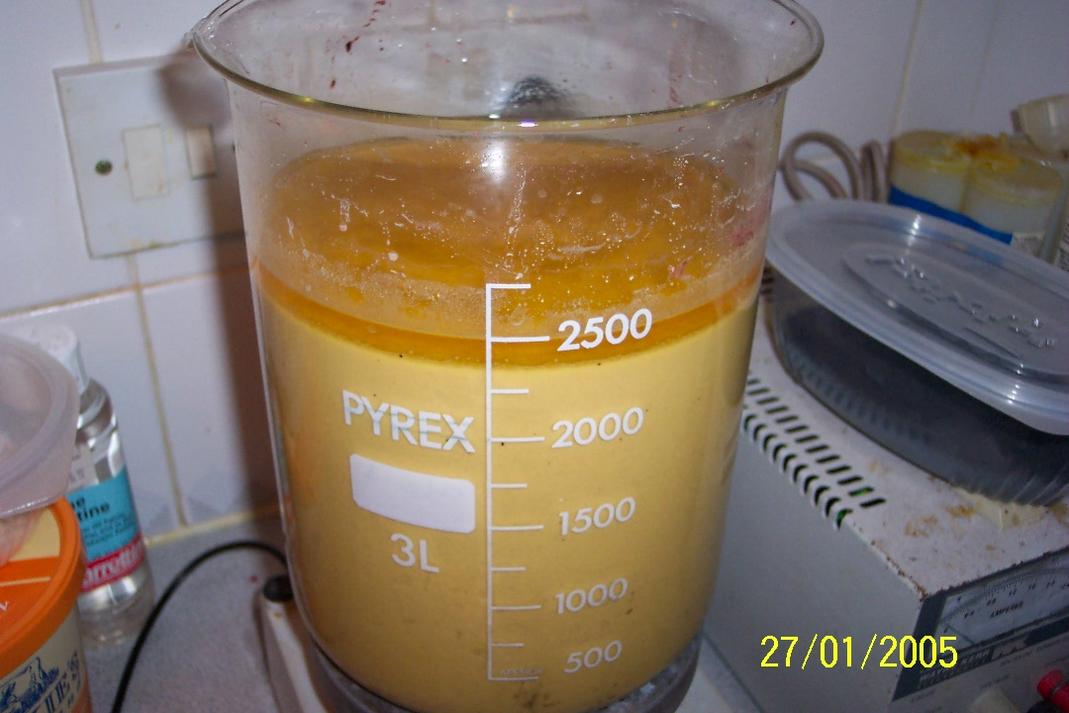

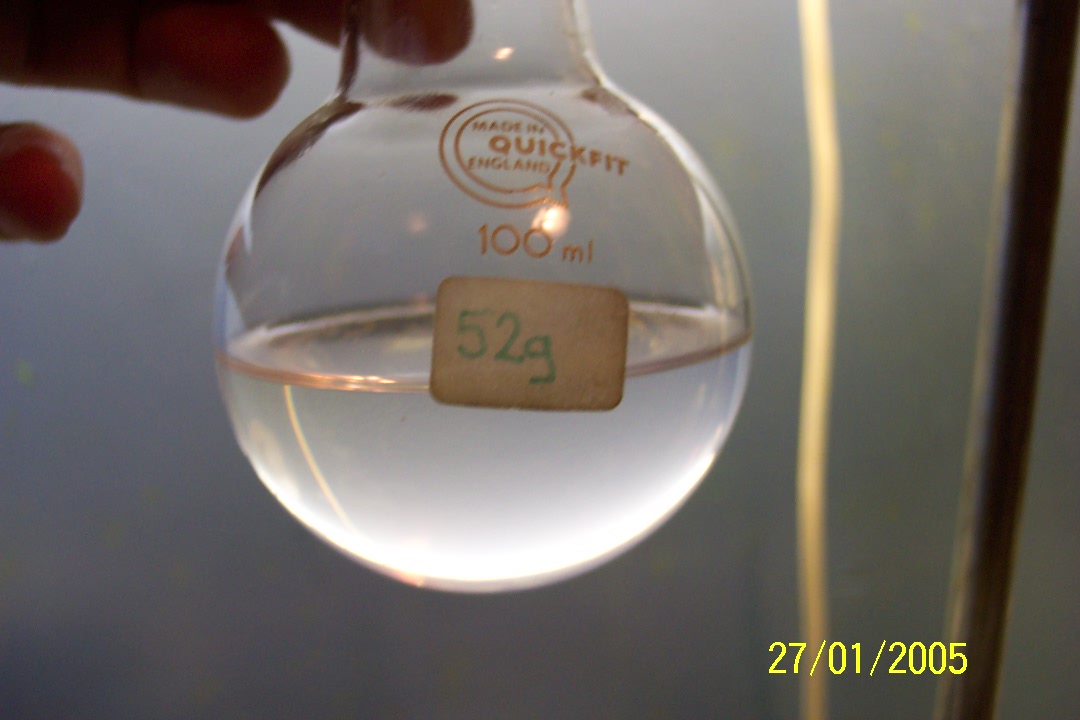

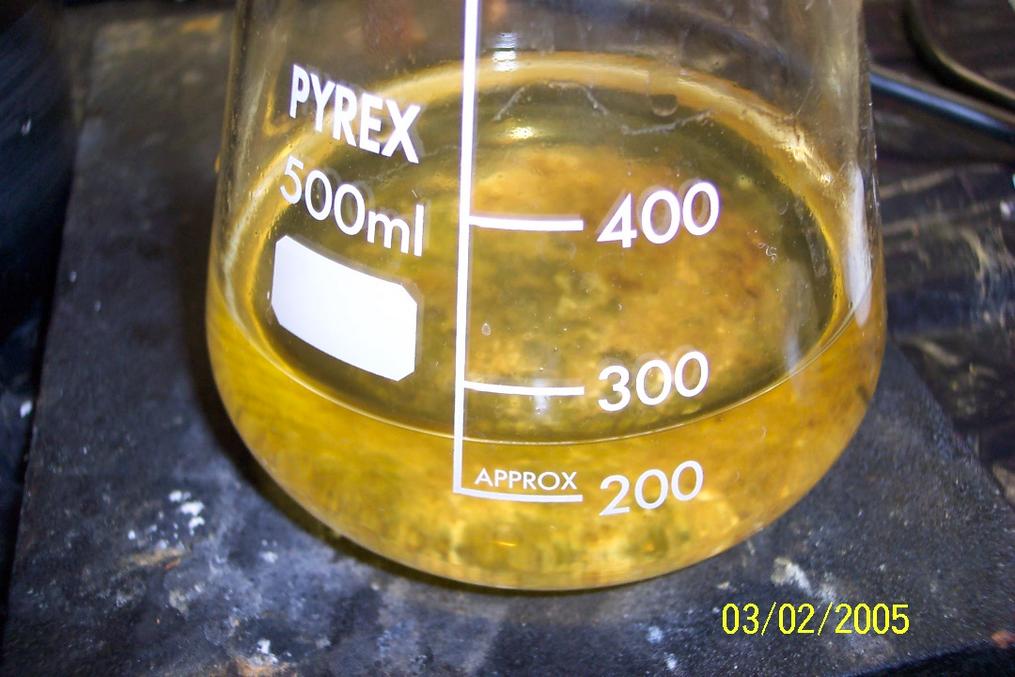

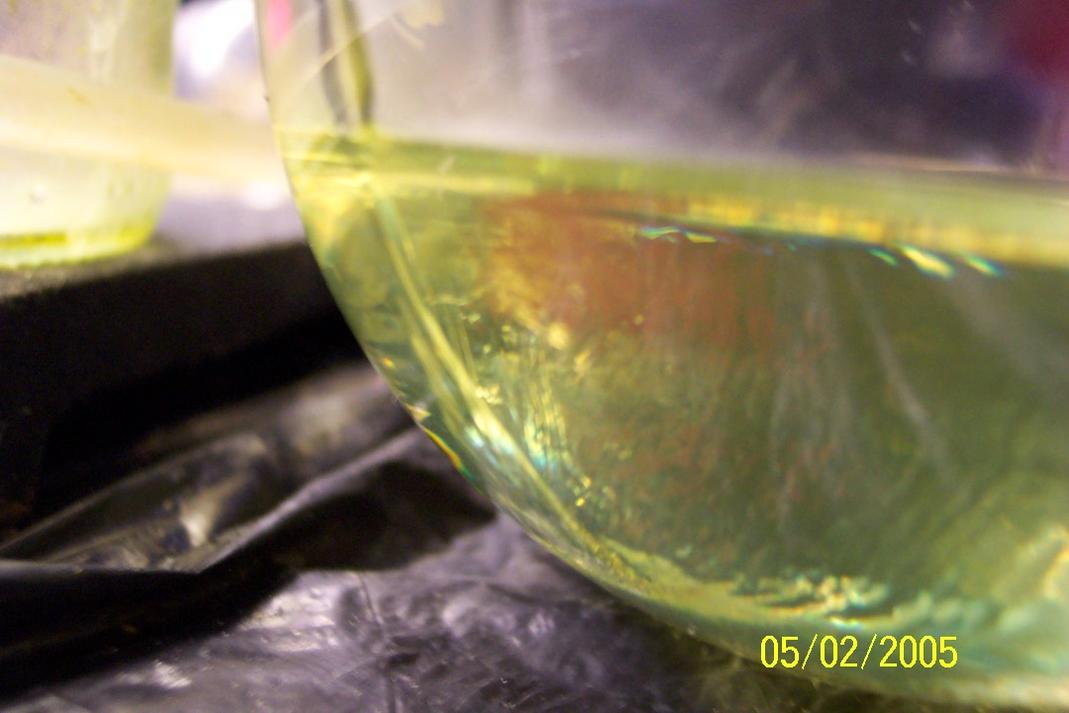

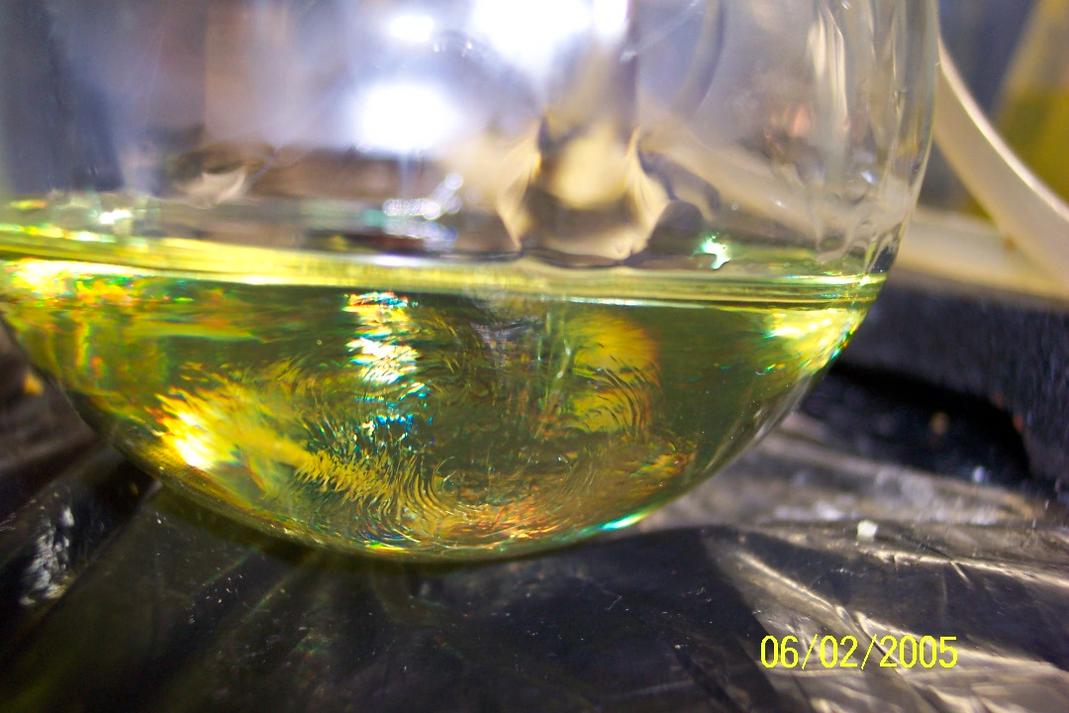

On cooling or upon addition of more (cold) concentrated sulfuric acid the oxidiser settles out in the form of lustrous, brown-red needles.

The product such obtained can be dissolved in organic acids, like acetic acid, and can be used in such solution to react with dissolved organic

compounds which otherwise would be destroyed by concentrated sulfuric acid.

The oxidiser itself remains unchanged in its solid form if all traces of water are excluded.

[Translated from: D.R.P. 205200, titled "Verfahren zur Herstellung eines Oxidationsmittels"]

The reaction involved in this process is:

MnO2 +MnSO4 +2H2SO4 --> Mn2(SO4)3 +2H2O

The preparation of this compound is comparable to the prep. of Mn-(IV)-sulfate, as described by neograviton, but the need of working with fuming hot

sulfuric acid is omitted, which seems to be a little healthier...

Also, like in neograviton's preparation, there is no need for purchasing watched items like potassium permanganate for the preparation of

activated manganese dioxide

An educated guess at last:

For the preparation of benzaldehyde from toluene, I think the procedure described by neograviton should work equally well with the use of

abovementioned Mn-(III)-sulfate, there is even no need of isolating this compound from the 60% sulfuric acid solution, use it as it is.

|

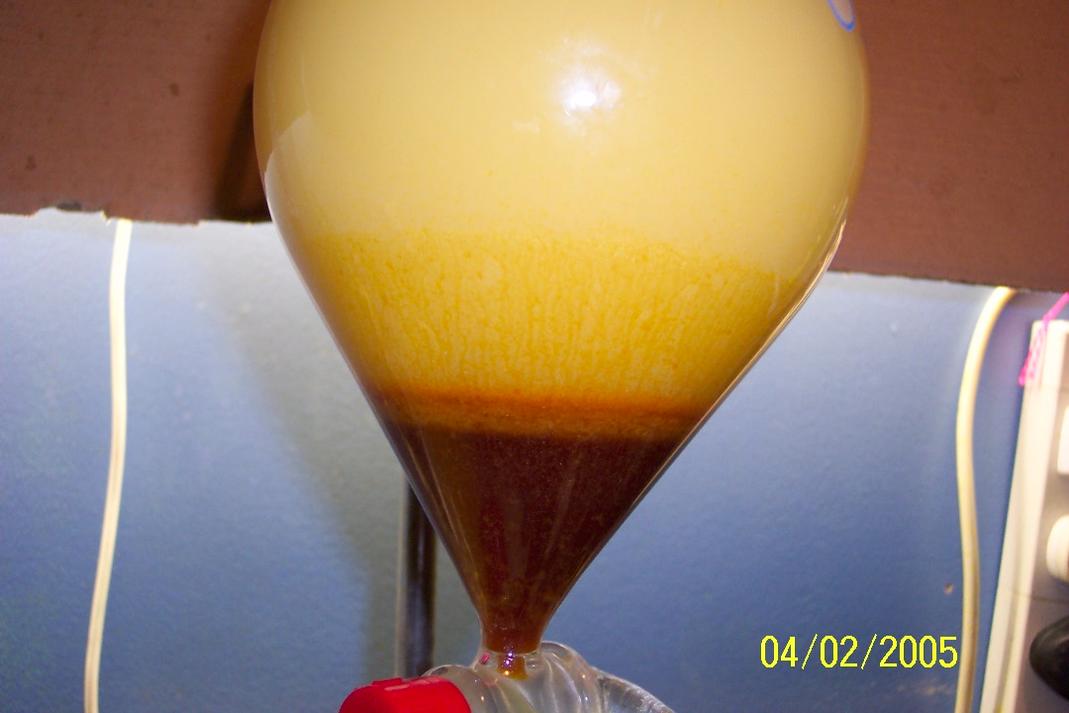

(I used vigorous stirring to break upper layer).

(I used vigorous stirring to break upper layer). but still that wouldn't

give precise aldehyde content..

but still that wouldn't

give precise aldehyde content..

. This reaction is more

suited for industry or for people who have cylinders, or for people who are really good at rigging up apparatti with 60 hoses and 10 washbottles,

suckback traps.

. This reaction is more

suited for industry or for people who have cylinders, or for people who are really good at rigging up apparatti with 60 hoses and 10 washbottles,

suckback traps.

But you bring a whole new meaning to digital photgraphy!

But you bring a whole new meaning to digital photgraphy!

.

.