kilowatt - 18-12-2021 at 06:10

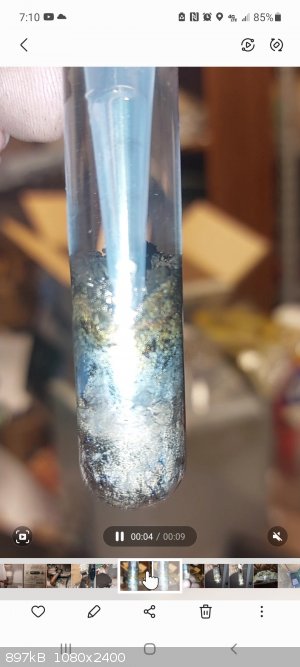

I need to prepare clean ampoules of cesium, and eventually rubidium and potassium for investment, use, or sale items. My plan for this is to fill

ampoules with purified (air and moisture removed) kerosene, and use a glass needle to insert the alkali metal under the kerosene. Then evacuate with a

vacuum pump until all the kerosene is gone, back-fill with argon, evacuate again and seal the ampoule with the ampoule body cooled in a bath of

fluorinert. I want to do 1/4" OD fused quartz ampoules filled with 1mmol of metal, and with enough empty space for me to seal, and to be used in high

vacuum systems and such.

I can draw pretty clean metal out of the middle of my test tubes, but I want to do a better job at separating the oxide/nitride slag so I don't

accidentally end up with a particle of that in any of my ampoules. A couple options I am considering are centrifuging it while molten, or using an

ultrasonic type setup while molten, to get it to separate into layers. I just don't want to break the glass, lose all that cesium and destroy

equipment or worse.

Additionally potassium and rubidium can form peroxides that would explode on any of these treatments. I intend to produce and keep those under only

purified kerosene with an argon cover in the first place so this doesn't happen, but I wish there was a way to destroy that or remove it if it did.