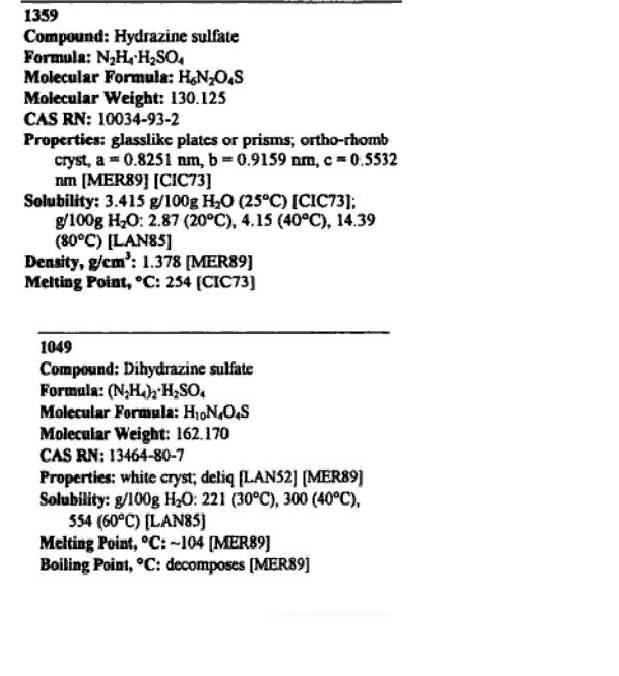

Yeah the Dihydrazine Sulfate reportedly is stable. The reason the acidic salt, the monohydrazine sulfate is the common form is because it is the low

solubility product precipitated from acidic solution which facilitates its isolation in relatively pure form from synthesis. So the monohydrazine

sulfate is the common form of commerce, and the common form for the reagent. But definitely there are other forms of further processed hydrazine

which are also stable and may be required for certain syntheses. It is a similar story for ammonia and other bases where various salts and/or even

the anhydrous base are stable but have their various differing properties and reactivity and storage requirements, toxicity, volatility, ect. ranging

from benign conditions to extreme. To make an analogy, hydrazine sulfate corresponds with ammonium bisulfate or sodium bisulfate and Dihydrazine

Sulfate is the neutral salt corresponding with ammonium sulfate or sodium sulfate which more correctly and precisely in reality are Diammonium Sulfate

and Disodium Sulfate.

As for the danger aspect of working with smaller volumes of material which should be easier to manipulate with the endproduct being the same hazard

....usually a simpler process manipulation of a smaller amount of raw material increases safety and is not any more risky ....so it seems it would

about the same or lower risk. I can't really report an observation on this because I haven't actually done this yet to confirm. What works on paper

doesn't necessarily always materialize that way in the experiment. But this one seems pretty straightforward like it ought to work okay.

There is another calcium salt of possible interest with regards to hydrazine conversion to azide and this is another possibility for experimentation

which was mentioned in another thread.

http://www.sciencemadness.org/talk/viewthread.php?tid=874&am...

It has seemed possible to me that an organic nitrite may facilitate the reaction somehow and is more selective in converting hydrazine to hydrazoic

acid than is free nitrous acid. It has therefore seemed possible that something like sorbitol or glycerin or isopropyl alcohol in an aqueous solution

of a neutral hydrazine salt such as Dihydrazine Sulfate, might react as a regenerable intermediate organic nitrite with Basic Calcium Nitrite

Ca(NO2)2 - Ca(OH)2 to yield an aqueous solution of Calcium Azide over precipitated Calcium Sulfate. The Calcium Azide solution might then be converted

to a solution of Sodium Azide with precipitation of Calcium Carbonate, by treatment of the solution with Sodium Carbonate. This is another

completely hypothetical and untested idea for an experiment.

It may not work at all in a beaker even though it seems to work fine on paper.

Attached is US4294813 which describes a synthesis of Basic Calcium Nitrite from Sodium Nitrite and Calcium Nitrate

|

Until then we shall examine what may be "other" bona fide methods than proposed by

either Curtius or Hogkinson, frankly both of which reports I greet with skepticism born of experience having difficulty confirming their reports. I

have successfully made azide many times and different ways, but all of these variations still have involved free hydrazine in alcohol reacted with an

organic nitrite in the presence of a base. It is perplexing to identify the alternate conditions where an aqueous reaction system may be used with

good results.

Until then we shall examine what may be "other" bona fide methods than proposed by

either Curtius or Hogkinson, frankly both of which reports I greet with skepticism born of experience having difficulty confirming their reports. I

have successfully made azide many times and different ways, but all of these variations still have involved free hydrazine in alcohol reacted with an

organic nitrite in the presence of a base. It is perplexing to identify the alternate conditions where an aqueous reaction system may be used with

good results.

Old Ph.D's don't go nutters with age, they only become "eccentric"

Old Ph.D's don't go nutters with age, they only become "eccentric"