Bucher Process.-The synthesis of sodium cyanide by the interaction of sodium carbonate, carbon and nitrogen in the presence of iron as a

catalyst, according to the equation Na2C03+4C+N2 = 2NaCN+3CO 3 constitutes a promising method of nitrogen fixation, the commercial development of

which is still in its infancy. The catalytic effect of iron in promoting this formation of cyanides. at relatively low temperatures (800-1,000° C.)

was noted by Thompson in 1839. Bucher (Jour. Indust. and Eng. Chem., 1917, 9 . 2 33) drew renewed attention to the process, which has recently been

developed industrially in the United States by the Nitrogen Products Co. According to the procedure adopted at Saltville,Virginia (Jour. Indust. and

Eng. Chem., 1919, II. Imo), coke is ground to a fineness of 200 mesh, and after the admixture of a small quantity of iron the required quantity of

soda ash is added. The charge is moistened slightly, kneaded, and extruded in the form of briquettes, which are dried by the action of flue gases. The

briquettes are placed in vertical iron or nichrome retorts, which are heated externally in firebrick furnaces to a temperature of 900 to 1,000° C., a

current of nitrogen being led through the retorts. The briquettes, after treatment, contain about 20% to 30% of cyanide, which, in the plant in

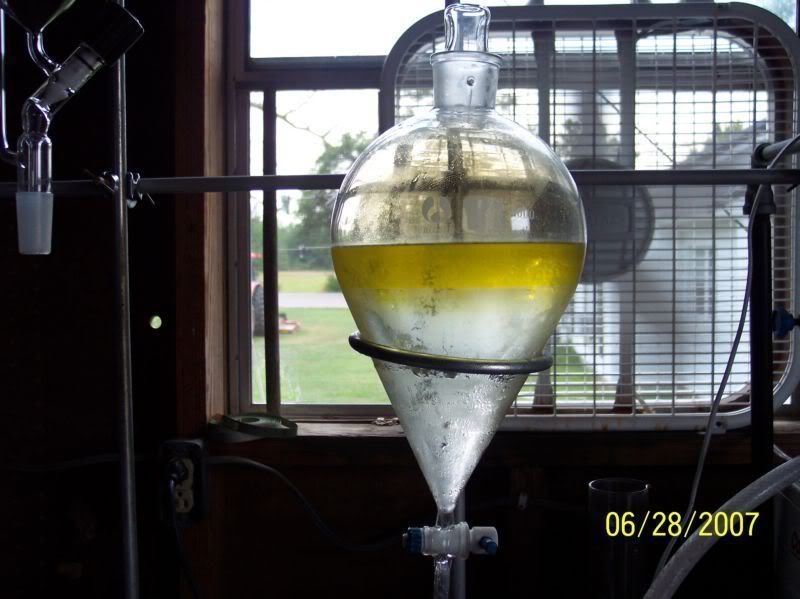

question, is removed in a somewhat novel manner by subsequent extraction with liquid ammonia, in which sodium cyanide is readily soluble. During this

extraction process, the main structure of the briquette remains undestroyed, and the uncombined residue may be used for further treatment with

nitrogen. The chief technical difficulty lies in the rapid deterioration of the iron retorts at the temperature employed for fixation, the life of

these being about 7 to 12 days. Nichrome retorts last longer, but are more expensive to replace. It has been proposed to use an electrically heated

type of furnace in which the charge itself forms the resistance. Further, pure nitrogen, although conducive to a high yield of cyanide, is not

essential for commercial success. Ferguson and Manning (Jour. Indust. and Eng. Chem., 1919, II. 94 6), in reviewing the replacement of nitrogen by

producer gas containing carbon monoxide, state that at 1,000°C. the presence of 15% of carbon monoxide in the nitrogen reduces the yield of cyanide

by about 30%, while, if the producer gas contains 60% of carbon monoxide, the yield is one-half of the value obtained with pure nitrogen. This

inhibitive effect of carbon monoxide, the reason for which lies in the reversibility of the equation Na 2 CO 3 +4C+N 2 2NaCN+3CO, is even more

pronounced at lower temperatures.

From: http://www.1911encyclopedia.org/Nitrogen_Fixation |

)

)

I am going to do this reaction with

aquenous solution + TBACl

I am going to do this reaction with

aquenous solution + TBACl

) and (during stirring with spoon) as H2O goes away, it spills into white powder. At this moment it looks like (previously prepared) KCN.

About KCN --> see page 4 of "Preparation of cyanides". Proof of content ? Read BTW1 in my last post (and yield of the precious nitrile was good

) and (during stirring with spoon) as H2O goes away, it spills into white powder. At this moment it looks like (previously prepared) KCN.

About KCN --> see page 4 of "Preparation of cyanides". Proof of content ? Read BTW1 in my last post (and yield of the precious nitrile was good

). Of course, some can say: it is bullshit, not NaCN in a jar but washing

powder... But this powder works

). Of course, some can say: it is bullshit, not NaCN in a jar but washing

powder... But this powder works

<sub>2</sub>C(OH)CN

<sub>2</sub>C(OH)CN